Data center waste heat power generation device based on liquid cooling IT (Internet Technology) equipment

A waste heat power generation and data center technology, applied in mechanical equipment, steam engine installations, electrical digital data processing, etc., can solve the problems of underutilization of cooling liquid heat, waste of low-temperature heat sources, etc. pressure, reducing the effect of the cooling device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

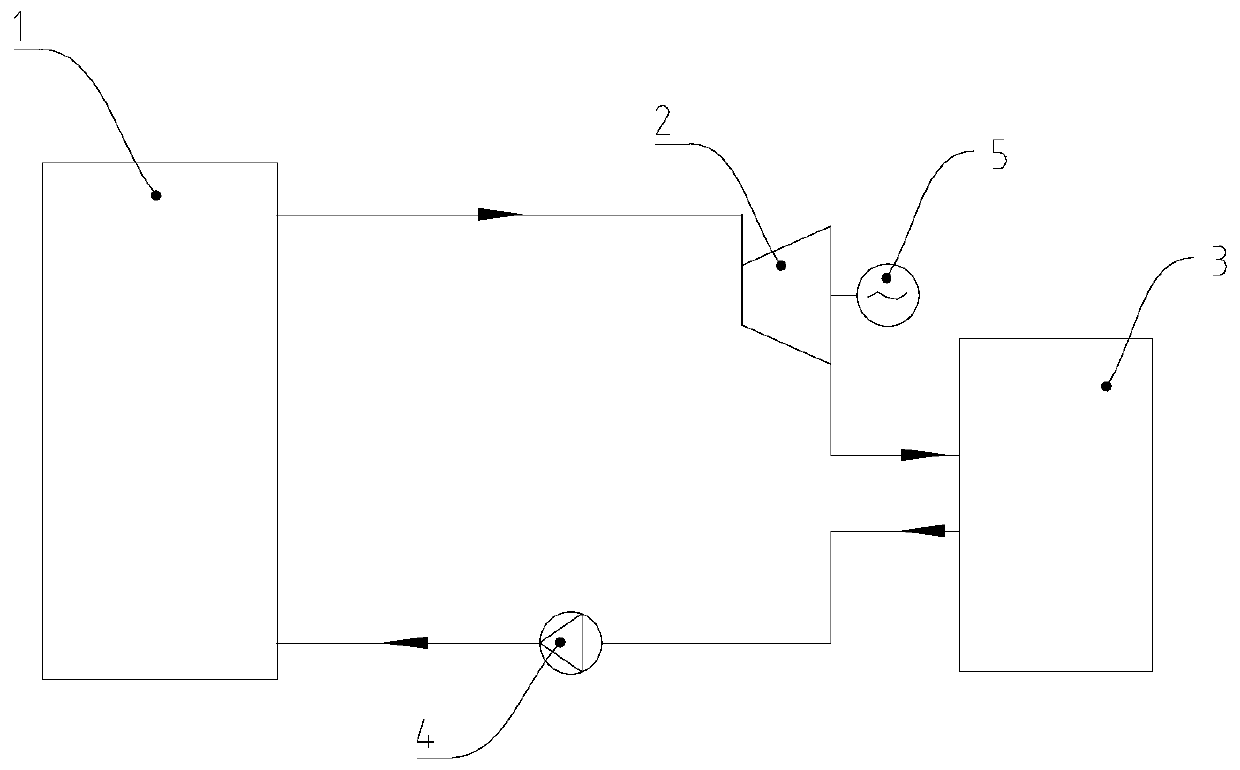

[0021] refer to figure 1 , a data center waste heat power generation device based on liquid-cooled IT equipment, including: an immersion-type liquid-cooled server 1, a turbine 2, a condenser 3, and a working medium pump 4 connected in sequence to form a circulation loop, that is, an immersion-type liquid-cooled server The outlet of 1 is connected to the inlet of turbine 2 , the outlet of turbine 2 is connected to the inlet of condenser 3 , and the outlet of condenser 3 is connected to the inlet of immersion liquid cooling server 1 through working medium pump 4 . The turbine 2 is also provided with a generator 5, the power output of the turbine 2 acts on the generator 5, and the condenser 3 is an evaporative condenser.

[0022] Working process: The submerged liquid-cooled server 1 generates heat and directly transfers the heat to the cooling liquid filled in it. The flat machine 2 does work, so that the turbine 2 drives the generator 5 to generate electricity. The steam from t...

Embodiment 2

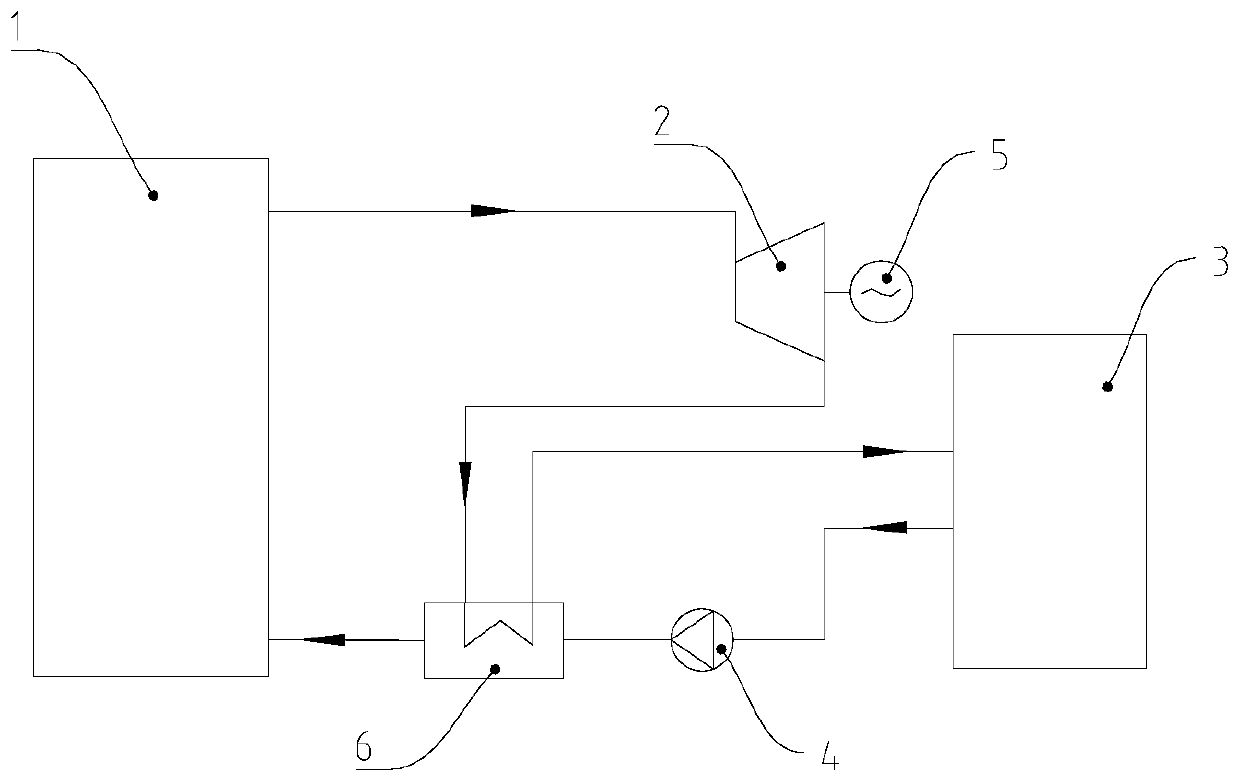

[0024] refer to figure 2 , this embodiment adds a regenerator 6 on the basis of embodiment 1, the turbine 2 is connected to the inlet of the high temperature side of the regenerator 6, the outlet of the high temperature side is connected to the condenser 3, and the outlet of the working medium pump 4 It is connected to the inlet of the low-temperature side of the regenerator 6 , and the outlet of the low-temperature side of the regenerator 6 is connected to the submerged liquid-cooled server 1 .

[0025] Working process: The submerged liquid-cooled server 1 generates heat and directly transfers the heat to the preheated coolant in the regenerator 6. The coolant absorbs the heat and evaporates into steam, which enters the turbine 2 and drives the turbine 2. Work, so that the turbine 2 drives the generator 5 to generate electricity. The steam from the turbine 2 first enters the regenerator 6 to exchange heat with the liquid from the working medium pump 4, dissipates part of the...

Embodiment 3

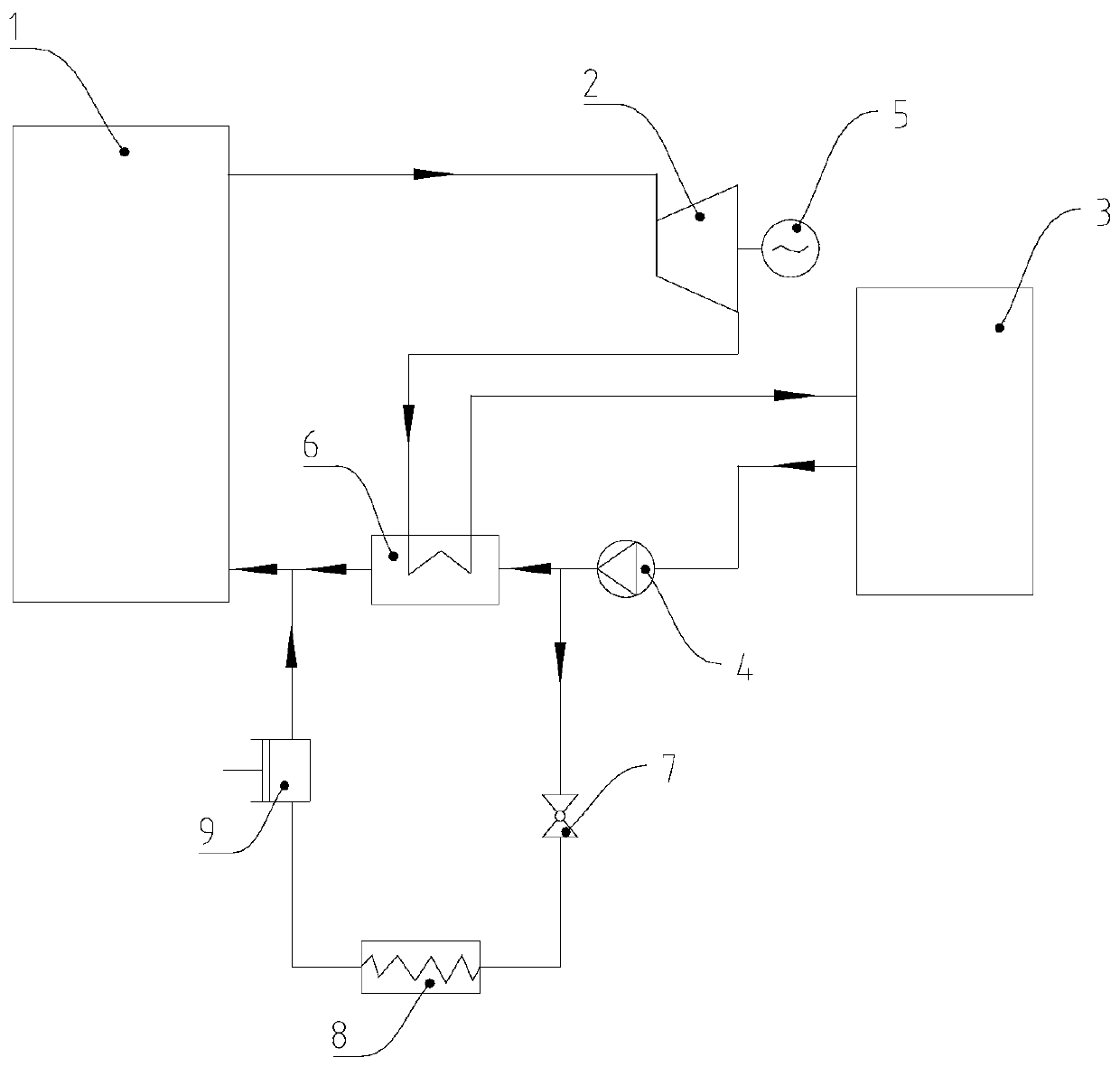

[0027] refer to image 3 In this embodiment, on the basis of Embodiment 2, a branch in parallel with the regenerator 6 is set at both ends of the low-temperature side of the regenerator 6, and the branch includes in turn: an expansion valve 7, an evaporator 8 and a compressor 9.

[0028] Working process: The submerged liquid-cooled server 1 generates heat and directly transfers the heat to the mixture of the coolant preheated in the regenerator 6 and the coolant heated up and pressurized by the compressor 9, and the coolant absorbs heat and evaporates The steam enters the turbine 2, drives the turbine 2 to do work, and the turbine 2 drives the generator 5 to generate electricity. Heat exchange, dissipate part of the heat, and then enter the condenser 3 to further condense into a liquid. The liquid from the condenser 3 is pressurized by the working medium pump 4 to the supercooled liquid under the evaporation pressure and enters the regenerator 6 to absorb heat. One way goes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com