Bimetal wear-resistant seamless composite steel pipe and forming process thereof

A composite steel pipe and bimetal technology, which is applied in the direction of pipes, rigid pipes, furnace types, etc., can solve the problems of tube length limitation, bimetallic pipe failure, and prone to delamination, and achieves less damage and strong connection stability. , the overall combination of strong effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

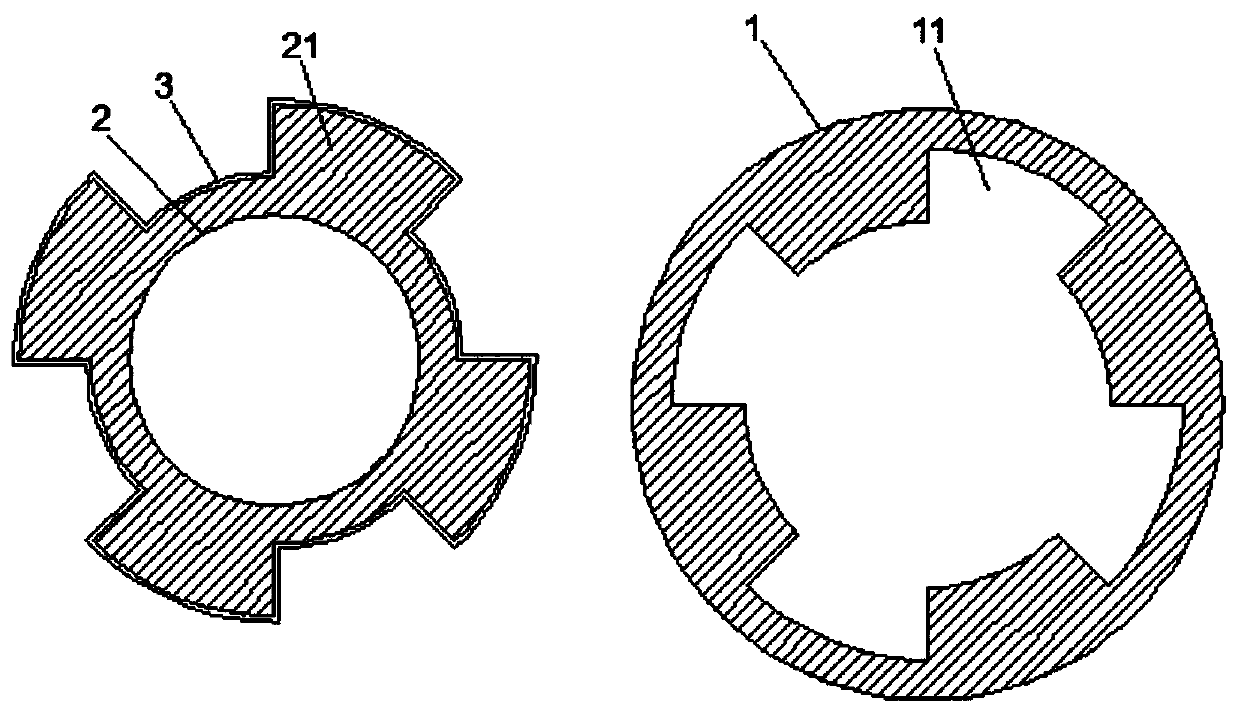

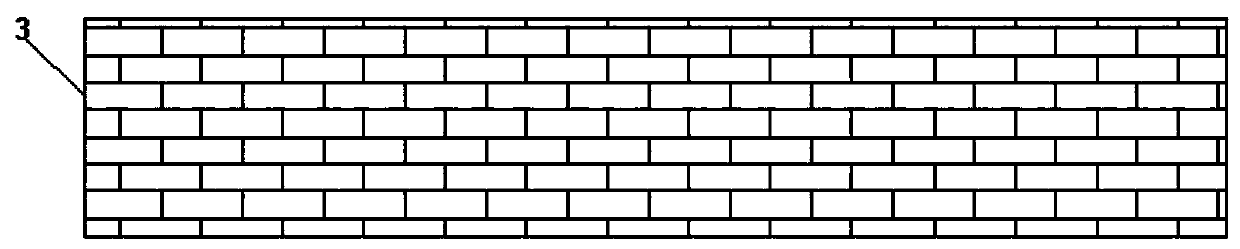

[0031] A bimetallic wear-resistant seamless composite steel pipe, comprising an outer pipe 1, an inner pipe 2 assembled and mated, and a transition surface 3 between the outer pipe 1 and the inner pipe 2, the inner wall of the outer pipe 1 has an annular array of inner slots 11, The circular array on the outer wall of the inner pipe 2 has external inserts 21 adapted to be inserted into the inner slots 11, the number of the inner slots 11 and the outer inserts 21 is 3-5, and the sections of the inner slots 11 and the outer inserts 21 are trapezoidal structure, there are 4 in the figure;

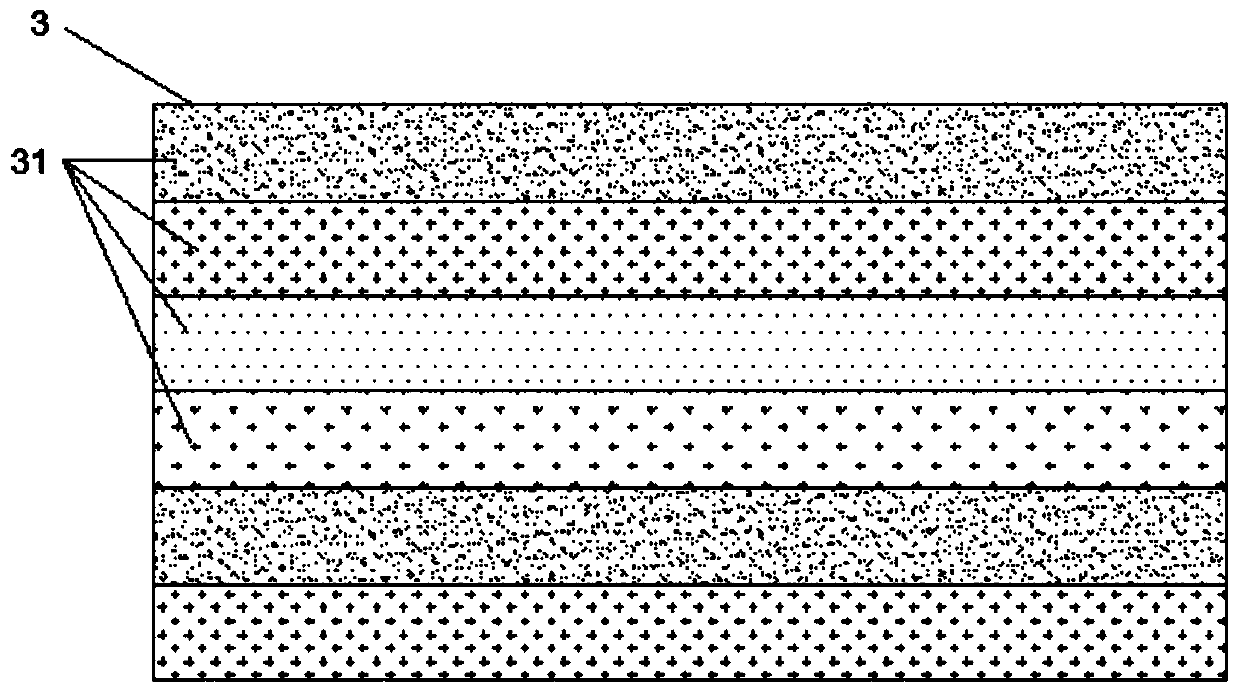

[0032] Among them, the material of the outer pipe 1 and the inner pipe 2 is selected according to the national standard requirements of the corresponding field, such as, but not limited to, any one of 304, 304L, 316, 316L, 347, 825, Q345, L245, and L360; the transition surface 3. Diversified metal composite layers with carbon fiber cloth 31 as the skeleton (composed of alternately laying strip...

Embodiment 2

[0041] A bimetal wear-resistant seamless composite steel pipe, including an outer pipe (Q345) assembled and matched, an inner pipe (304), and a transition surface between the outer pipe and the inner pipe. The circular array on the outer wall of the pipeline has external inserts that fit and plug into the inner slots. The number of the inner slots and the outer inserts is four, and the cross-section of the inner slots and the outer inserts is a trapezoidal structure.

[0042] The preparation process of the transition surface is as follows. Take the unidirectional carbon fiber cloth, place it in 8wt% polyvinyl alcohol aqueous solution, soak it at 60±2°C for 10 minutes, take it out and dry it, then put it in 36.5wt% sodium silicate solution, take out the liquid The amount is 95%, and then the composite particles are laid in strips on the front and back of the unidirectional carbon fiber cloth. After the laying is completed, it is dried at 55°C for 20 minutes, and then placed in a...

Embodiment 3

[0051] A bimetallic wear-resistant seamless composite steel pipe, including an outer pipe (Q345) and an inner pipe (L245) for assembly and matching, and a transition surface between the outer pipe and the inner pipe. The circular array on the outer wall of the pipeline has external inserts that fit and plug into the inner slots. The number of the inner slots and the outer inserts is four, and the cross-section of the inner slots and the outer inserts is a trapezoidal structure.

[0052] The preparation process of the transition surface is as follows. Take the unidirectional carbon fiber cloth, put it in 8wt% polyvinyl alcohol aqueous solution, soak it at 65±1°C for 10 minutes, take it out and dry it, then put it in 35wt% sodium silicate solution, take out the amount of liquid 90%, and then lay composite particles on the front and back of the unidirectional carbon fiber cloth in the form of strips. After the laying is completed, dry at 60°C for 10 minutes, and place it in a 35wt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Pressure resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com