Thin-film capacitor integrating EMC and discharge functions and motor controller thereof

A technology for motor controllers and thin film capacitors, applied in the direction of thin film/thick film capacitors, capacitors, laminated capacitors, etc., can solve the problems of poor feasibility of epoxy potting process, damage to magnetic materials, poor firmness and insulation performance, etc. Achieve the effects of improving EMC performance and safety, reducing differential mode and common mode signals, and improving insulation reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

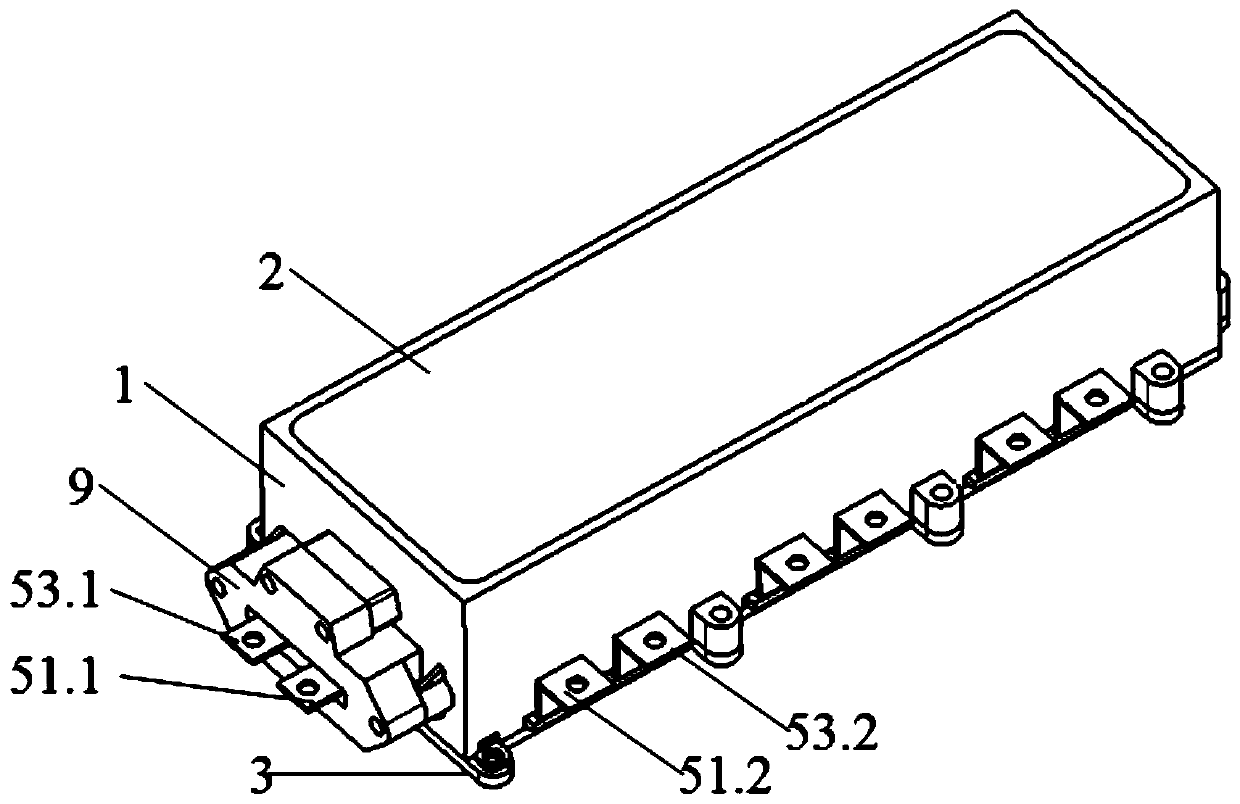

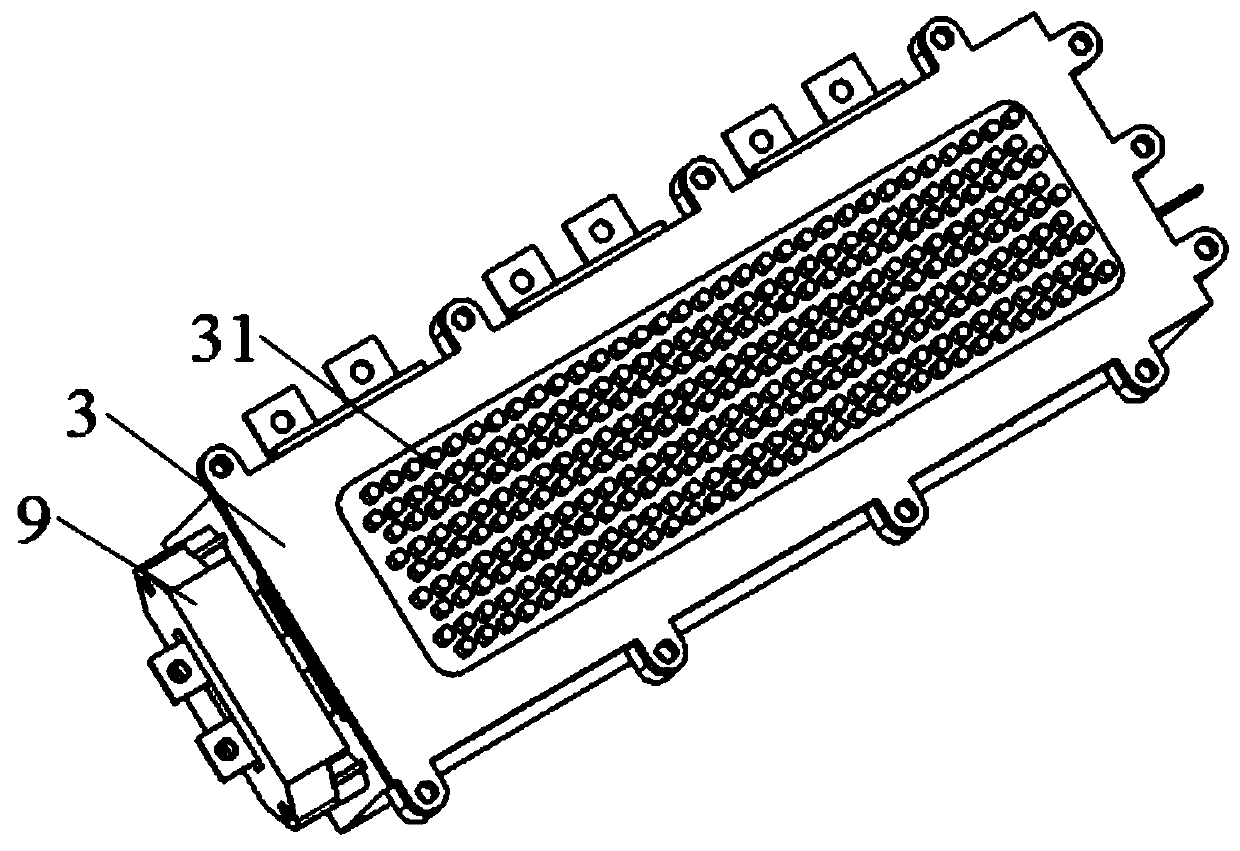

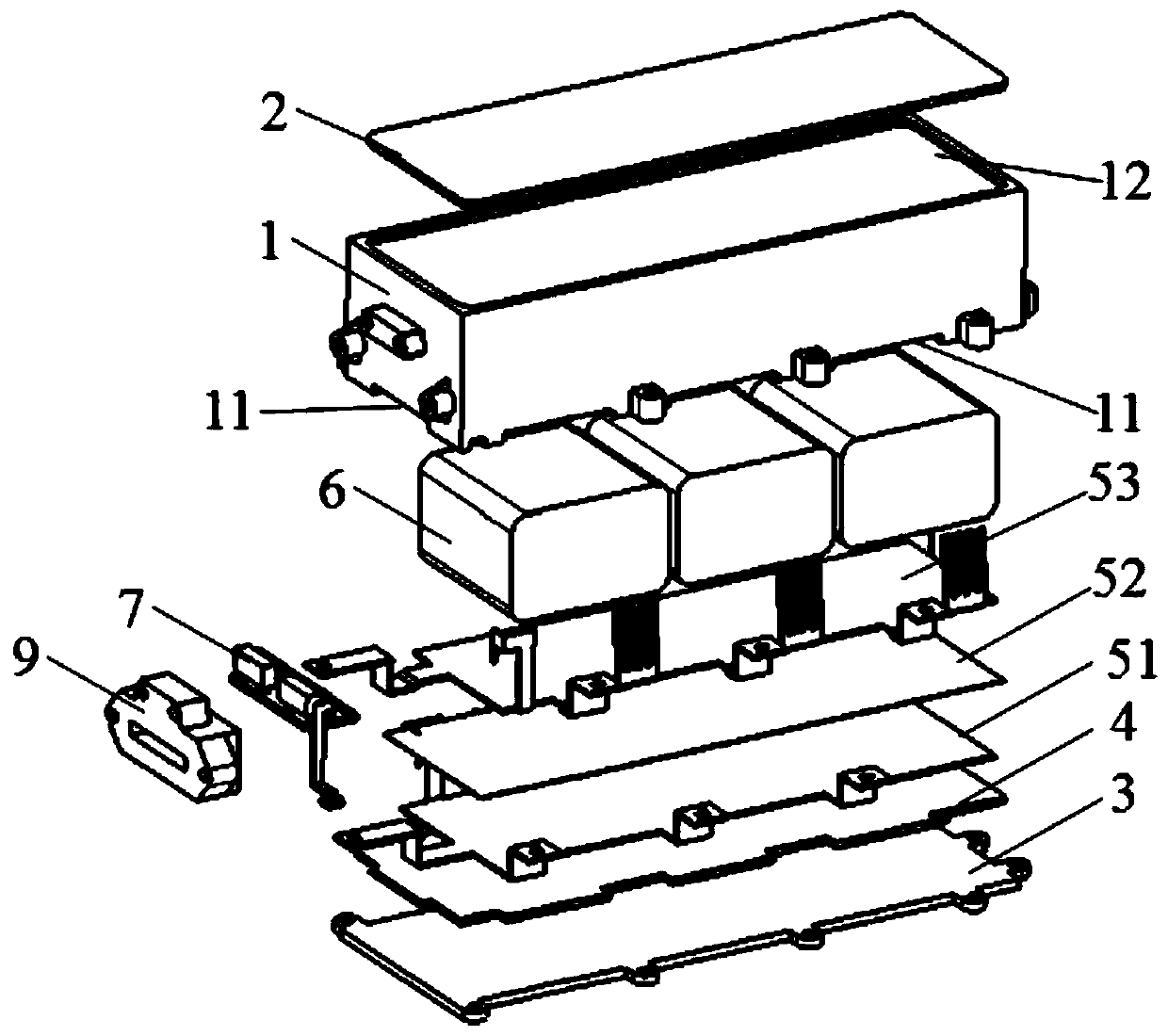

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0033] Such as Figure 1-5 As shown, the present invention provides a film capacitor with integrated EMC and discharge functions, including a capacitor case 1 with a top seal and a bottom opening, and a heat dissipation upper cover 2 and a water-cooled bottom plate 3 respectively arranged on the upper and lower ends of the capacitor case 1. Inside the casing 1, there are thermally conductive insulating pads 4, laminated busbars 5, and X capacitor core rolls 6 in order from bottom to top. The laminated busbars 5 are provided with EMC components including Y capacitors 71, bleeder resistors 72, and PCB boards 73. Module 7, the capacitor case 1 is filled with epoxy encapsulant 8 to package the X capacitor core roll 6 and the EMC module 7, and the surface of the capacitor case 1 is provided with a magnetic ring 9 for the input terminal of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com