Light emitting diode with PIPN structure and preparation method thereof

A technology of light-emitting diodes and structural layers, which is applied to electrical components, circuits, semiconductor devices, etc., can solve the problem of excessively fast decay of light-emitting diode luminous efficiency, and achieve the effects of reducing electron transmission efficiency, reducing built-in electric field, and improving collision probability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

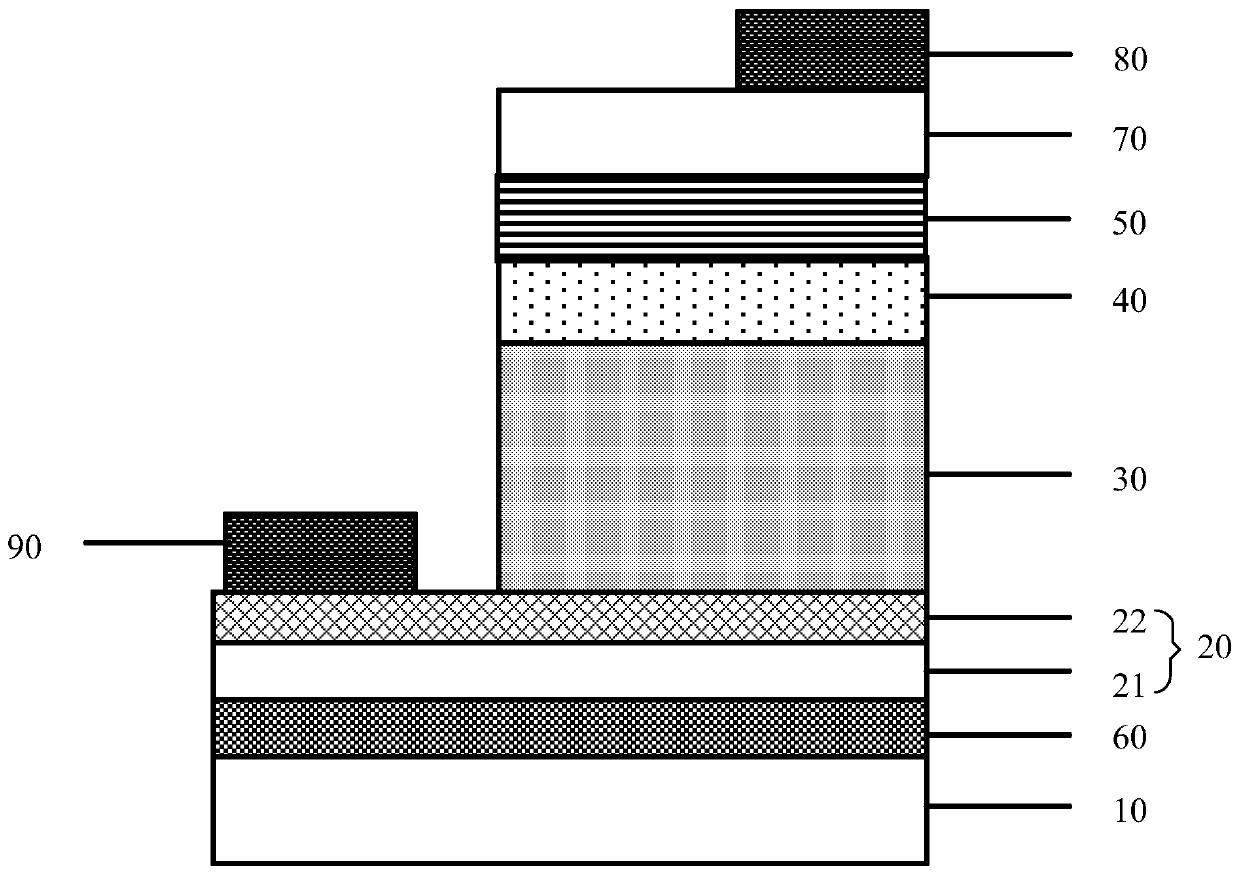

[0088] Correspondingly, the embodiment of the present application provides a method for preparing a light-emitting diode with a PIPN structure, such as Figure 4 shown, including:

[0089] S101: providing a base;

[0090] S102: sequentially forming an N-type structure layer, a P-type insertion layer, an active layer, an electron blocking layer, and a P-type hole supply layer on the surface of the substrate.

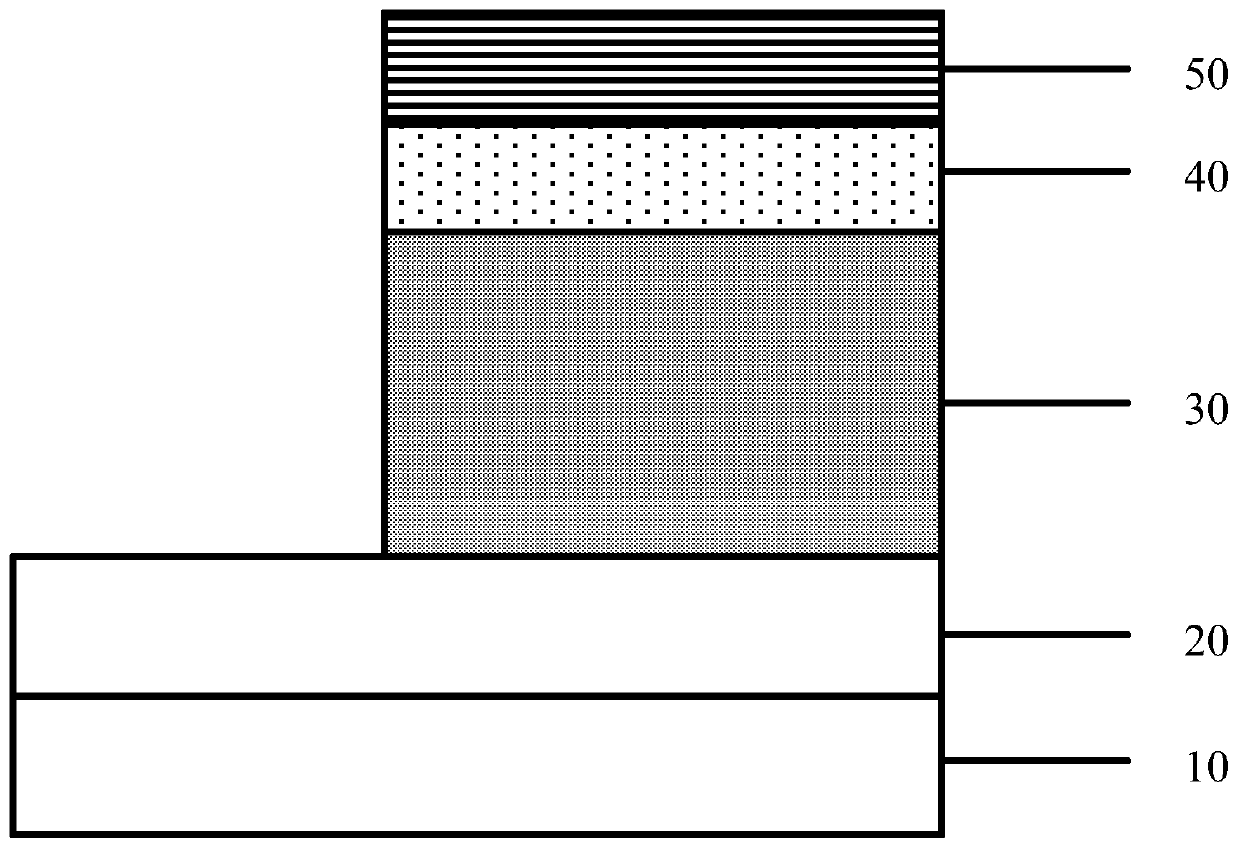

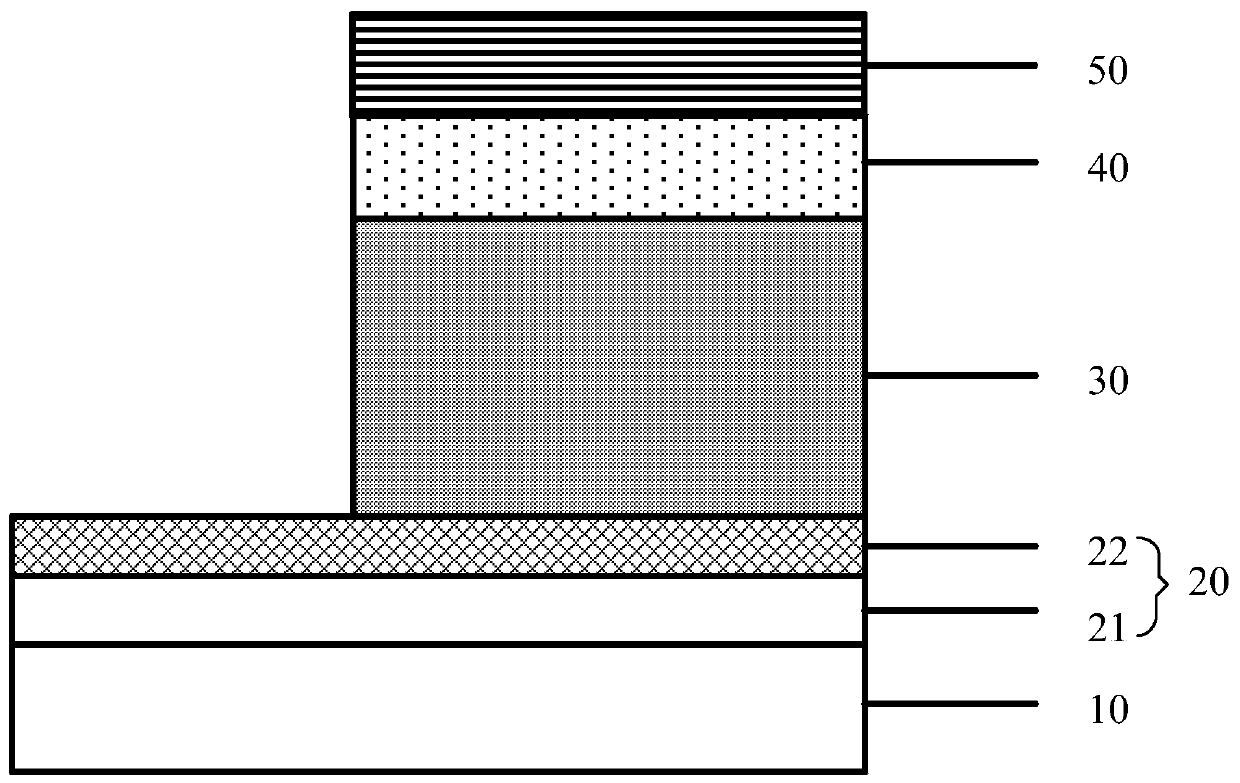

[0091] The cross-sectional structure schematic diagram of the light-emitting diode of the PIPN structure refers to figure 1 , for GaN LEDs, refer to figure 2 , optionally, the N-type structure layer includes: a U-GaN layer and an N-GaN electron supply layer; wherein,

[0092] The N-GaN electron supply layer is located on the surface of the U-GaN layer away from the substrate;

[0093] The active layer includes multiple layers of indium gallium nitride layers and multiple layers of gallium nitride layers alternately stacked;

[0094] The P-type hole supply layer incl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com