A DC motor parallel control system and current following control method

A DC motor and control system technology, applied in the direction of DC motor speed/torque control, control system, and control of multiple DC motors, can solve problems such as increased cost, programming difficulties, and complicated equipment connections, and achieve current response speed Fast, excellent control accuracy and stability, superior effect of real-time control performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In the description of the present invention, it should be noted that unless otherwise specified and limited, the terms "installation", "connection" and "connection" should be understood in a broad sense, for example, it can be a fixed connection or a detachable connection. Connected, or integrally connected; it may be mechanically connected or electrically connected; it may be directly connected or indirectly connected through an intermediary, and it may be the internal communication of two components. Those of ordinary skill in the art can understand the specific meanings of the above terms in the present invention in specific situations.

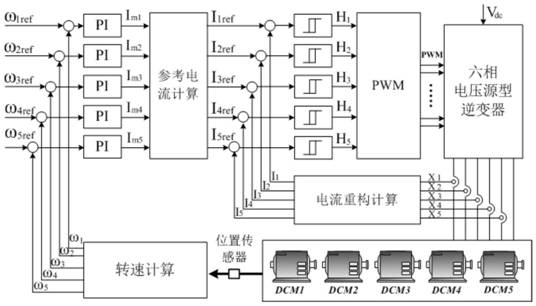

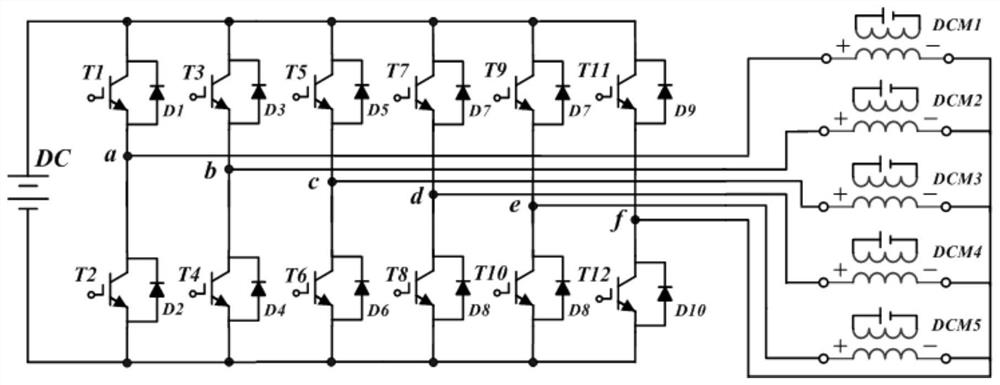

[0048] see figure 1 , the present invention provides a DC motor parallel control system, comprising:

[0049] Speed adjustment module: adjust the difference between the reference speed and the actual speed.

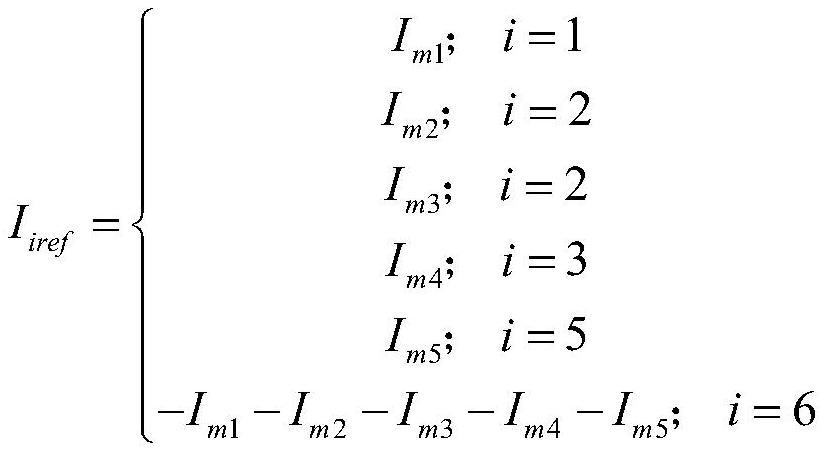

[0050] Reference current calculation module: use the output signals of the five speed regulation modules to calculate six r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com