Regeneration and recovery method of retired nickel cobalt lithium manganate battery cathode material

A technology of lithium nickel cobalt manganese oxide and battery positive electrode, which is applied in the field of regeneration and recovery of positive electrode materials, can solve the problems of polluted environment, low metal recovery rate, and complicated operation of treatment methods, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

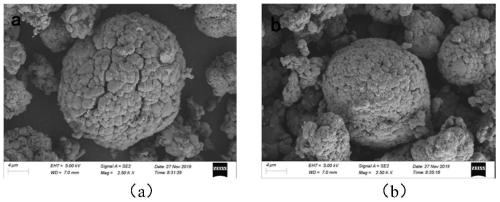

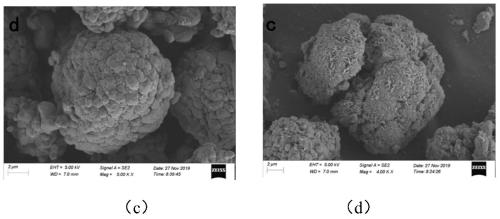

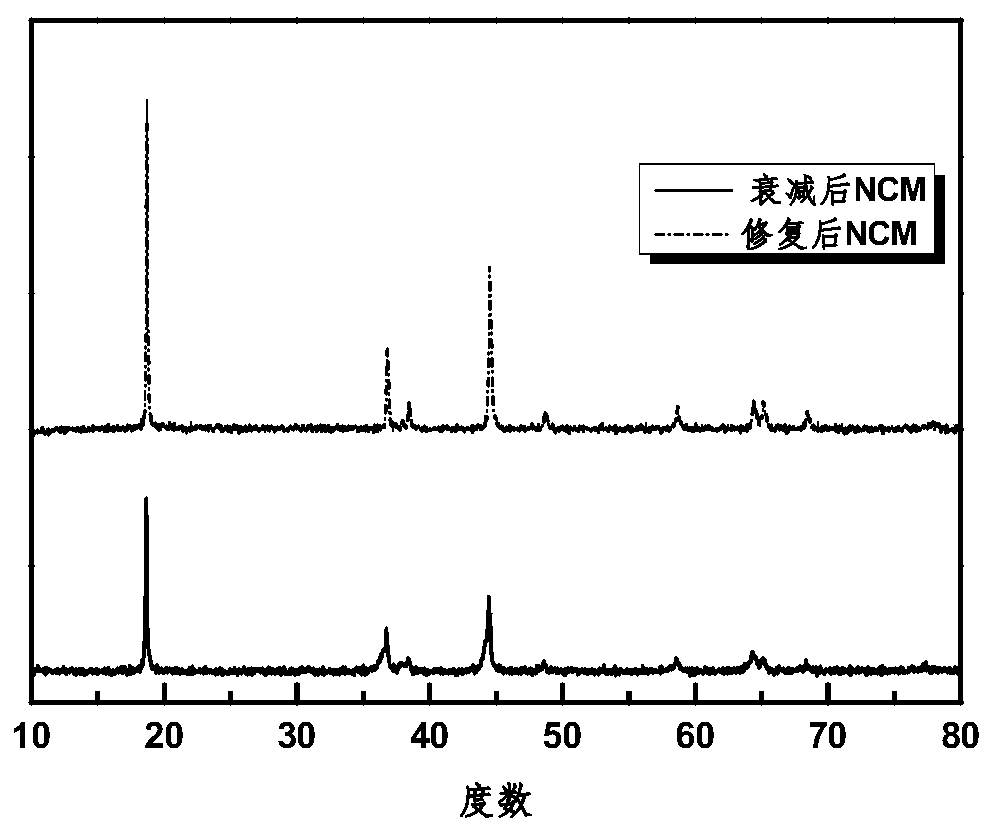

Image

Examples

Embodiment 1

[0029] In this embodiment, a method for regenerating and recycling the cathode material of a decommissioned nickel-cobalt lithium manganate battery comprises the following steps:

[0030] (1) Discharge the decommissioned lithium-ion battery three times to reduce the energy in the battery system, and then disassemble it to obtain the positive electrode sheet;

[0031] (2) Put the positive electrode sheet obtained in step (1) into a calciner, calcinate at 500°C, take it out for about 30 minutes, pass through a 200-mesh screen to remove aluminum foil and other impurities, and obtain a high-purity positive electrode material;

[0032] (3) adding lithium salts such as lithium nitrate, lithium carbonate, lithium hydroxide to the positive electrode material obtained in step (2) and mixing by ball milling;

[0033] (4) Put the mixed material obtained in step (3) into an atmosphere calcination equipment, and calcine at a high temperature of 450° C. for 5 hours under an oxygen atmospher...

Embodiment 2

[0036] In this embodiment, a method for regenerating and recycling the cathode material of a decommissioned nickel-cobalt lithium manganate battery comprises the following steps:

[0037] (1) Discharge the decommissioned lithium-ion battery three times to reduce the energy in the battery system, and then disassemble it to obtain the positive electrode sheet;

[0038] (2) Put the positive electrode sheet obtained in step (1) into a calciner, calcined at 300°C, take it out for about 6 hours, pass through a 200-mesh screen to remove aluminum foil and other impurities, and obtain a high-purity positive electrode material;

[0039] (3) adding lithium salts such as lithium nitrate, lithium carbonate, lithium hydroxide to the positive electrode material obtained in step (2) and mixing by ball milling;

[0040] (4) Put the mixed material obtained in step (3) into the atmosphere calcination equipment, calcine at 600° C. for 4 hours under an oxygen atmosphere, and obtain a repaired posi...

Embodiment 3

[0043] In this embodiment, a method for regenerating and recycling the cathode material of a decommissioned nickel-cobalt lithium manganate battery comprises the following steps:

[0044] (1) Discharge the decommissioned lithium-ion battery 5 times to reduce the energy in the battery system, and then disassemble it to obtain the positive electrode sheet;

[0045] (2) Put the positive electrode sheet obtained in step (1) into a calciner, calcined at 600°C, take it out for about 30 minutes, pass through a 200-mesh screen to remove aluminum foil and other impurities, and obtain a high-purity positive electrode material;

[0046] (3) adding lithium salts such as lithium nitrate, lithium carbonate, lithium hydroxide to the positive electrode material obtained in step (2) and mixing by ball milling;

[0047] (4) Put the mixed material obtained in step (3) into an atmosphere calcination equipment, calcine at a high temperature of 300° C. for 6 hours under an oxygen atmosphere, and ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com