Method for removing nitrate in underground water by using hydrogen autotrophic denitrification granular sludge

A technology for autotrophic denitrification and nitrification, which is applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc. Problems such as nitrite accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

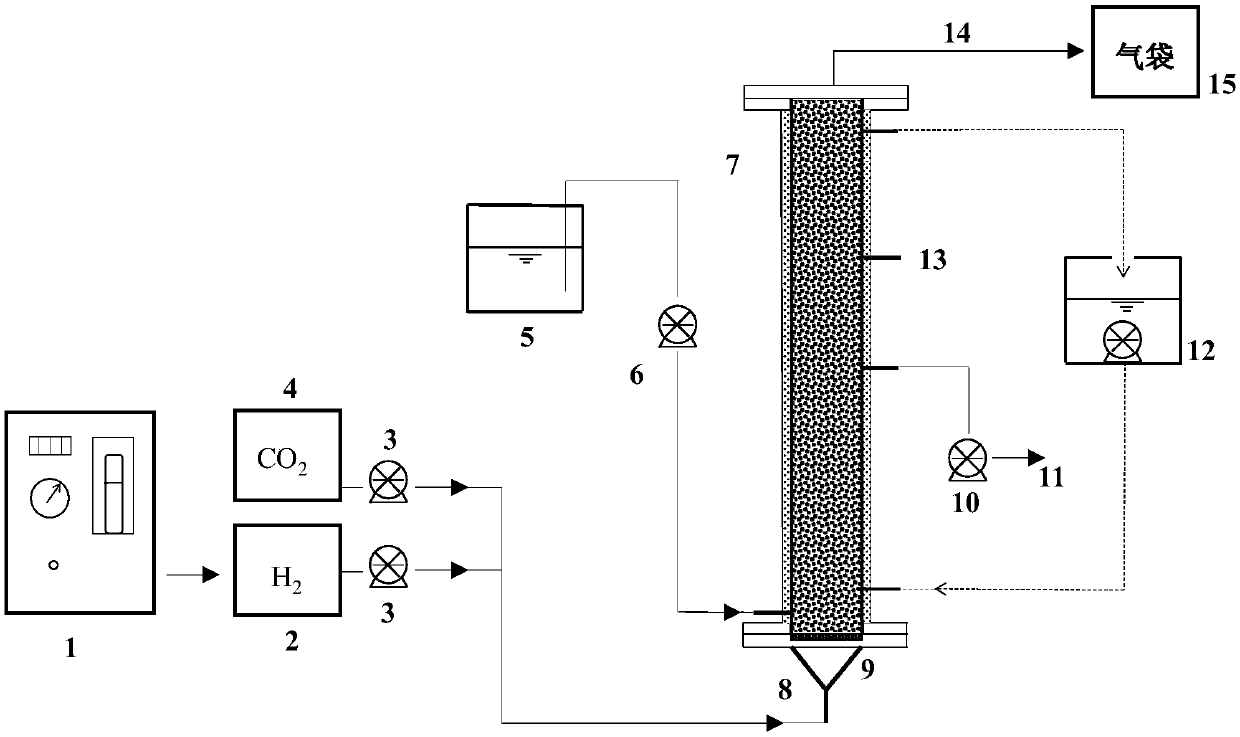

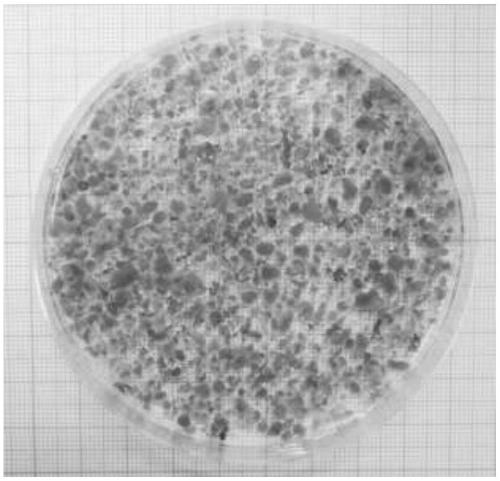

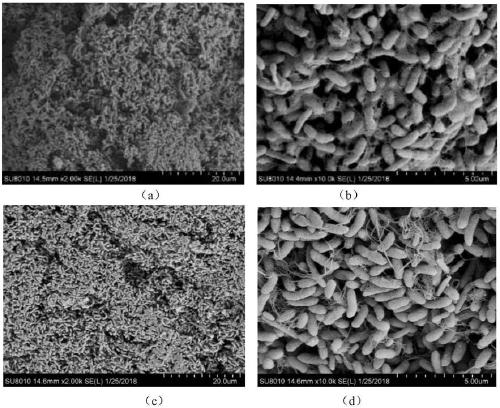

[0062] Embodiment 1, cultivating hydrogen autotrophic denitrification granular sludge

[0063] 1) Domestication and cultivation of hydroautotrophic denitrification flocculent sludge

[0064] Take the activated sludge of ordinary municipal sewage plant as inoculation sludge, the concentration is about 2.3gVSS / L, after inoculation, use H 2 Semi-continuous culture with self-prepared nutrient solution for 60 days. The composition of the culture solution is (contains the following substances per liter): 1.62gKNO 3 ,0.5gNaHCO 3 ,0.55gNaH 2 PO 4 2H 2 O, 2.11g K 2 HPO 4 ·3H 2 O and trace elements 7.3mgCaCl 2 2H 2 O,5.0mgFeSO 4 ·7H 2 O, 2.5 mg MnCl 2 4H 2 O, 0.5 mg CoCl 2 ·6H 2 O, 0.5mg (NH 4 ) 6 Mo 7 o 24 4H 2 O0.22mgZnSO 4 ·7H 2 O and 0.2 mg CuSO 4 ·5H 2O. The method of domestication and culture is sequential batch, and the sequence batch cycle is 12h. The pH of the culture system is 7.0±0.5, and the temperature is 30±1.0°C.

[0065] 2) The hydroautotrophi...

Embodiment 2

[0068] Example 2, using hydrogen autotrophic denitrification granular sludge reactor to treat simulated groundwater

[0069] Utilize the hydroautotrophic denitrification granular sludge cultivated in Example 1 to treat groundwater, maintain the reaction temperature at 30±0.5°C, add an appropriate amount of KNO 3 The simulated groundwater was used as the reactor feed water, and the denitrification effect, stability and effluent NO of the reactor were investigated. 2 - -N levels.

[0070] The sludge used in this test is the hydroautotrophic denitrification granular sludge cultivated in Example 1, and the inoculation sludge concentration in the reactor is 2.44g VSS / L.

[0071] The granular sludge reactor operates continuously for 12 days in accordance with the SBR method, and each SBR cycle is 35 minutes, including water inflow for 3 minutes, reaction for 22 minutes, precipitation for 8 minutes, and drainage for 2 minutes. The test water is to add a certain amount of KNO 3 ta...

Embodiment 3

[0075] Example 3, using hydrogen autotrophic denitrification granular sludge reactor to treat simulated groundwater under low temperature conditions

[0076] Utilize the hydroautotrophic denitrification granular sludge cultivated in Example 1 to treat groundwater, maintain the reaction temperature at 15±0.3°C, add an appropriate amount of KNO 3 The simulated groundwater was used as the reactor feed water, and the denitrification effect, stability and effluent NO of the reactor were investigated. 2 - -N levels.

[0077] The sludge and reactor used in this test are the hydrogen autotrophic denitrification granular sludge and sludge after the end of Example 2.

[0078] The granular sludge reactor operates continuously for 11 days in accordance with the SBR method, in which the cycle is 85 min for 7 days and the cycle is 75 min for 4 days. When the cycle is 85 minutes, water is fed for 3 minutes, reaction is 72 minutes, precipitation is 8 minutes, and water is drained for 2 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com