Anaerobic ammonia oxidation denitrification system and method for low-carbon-source sewage

An anammox and sewage technology, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of low efficiency of anammox reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

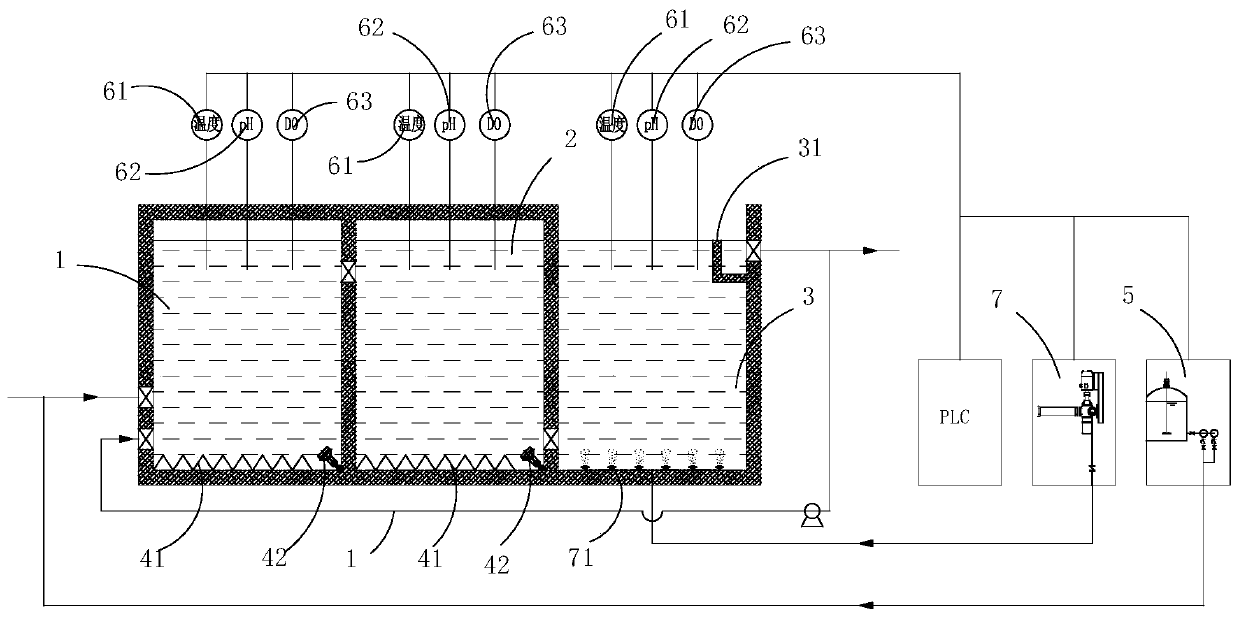

[0034] Such as figure 1 As shown, a low-carbon source sewage anaerobic ammonium oxidation denitrification system includes a regulating tank 1, which is suitable for adjusting the pH value, dissolved oxygen and temperature of sewage; Anaerobic ammonium oxidation treatment for sewage; and aerobic pool 3 connected with anaerobic ammonium oxidation pool 2, suitable for aerobic treatment of sewage.

[0035] The regulating pool 1 is provided with a sewage inlet for passing in sewage, and the aerobic pool 3 is provided with a water outlet.

[0036] Specifically, in this embodiment, a heating coil 41 and an agitator 42 are respectively set in the regulating tank 1 and the anammox tank 2 . The heating coil 41 circulates hot water to control the temperature of the sewage in the regulating tank 1 and the anammox tank 2 respectively, and the mixer 42 is used to stir the sewage to make the sewage react better.

[0037] Specifically, in this embodiment, an aerator 71 is provided in the ae...

Embodiment 2

[0049] A method for denitrification by anaerobic ammonium oxidation of low-carbon source sewage, using the anaerobic ammonium oxidation denitrification system for low-carbon source sewage of Embodiment 1, comprising the following steps:

[0050] In step a, the sewage is passed into the regulating tank 1, and the temperature, pH and dissolved oxygen parameters of the sewage are adjusted, so that the sewage meets the requirements of the anammox process;

[0051] Specifically, when the outside temperature is low, the heating coil 41 is heated by circulating hot water; the dosing device 5 adds acid and alkali to maintain the pH stability of the sewage.

[0052] The mixer 42 stirs to fully mix the sewage;

[0053] In step b, the sewage adjusted in step a is passed into the anammox tank 2, and the sewage reacts in the anammox tank 2 to generate nitrogen to degrade ammonia nitrogen and nitrous nitrogen in the sewage;

[0054] The nitrogen gas produced by the reaction is discharged f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com