Chloride ion permeation resistant concrete and construction method thereof

A chloride ion penetration and concrete technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of durability only considering the (water) penetration level, different technical levels, and different control methods. To achieve the effect of improving the anti-chloride ion penetration performance, improving the overall strength, and improving the impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

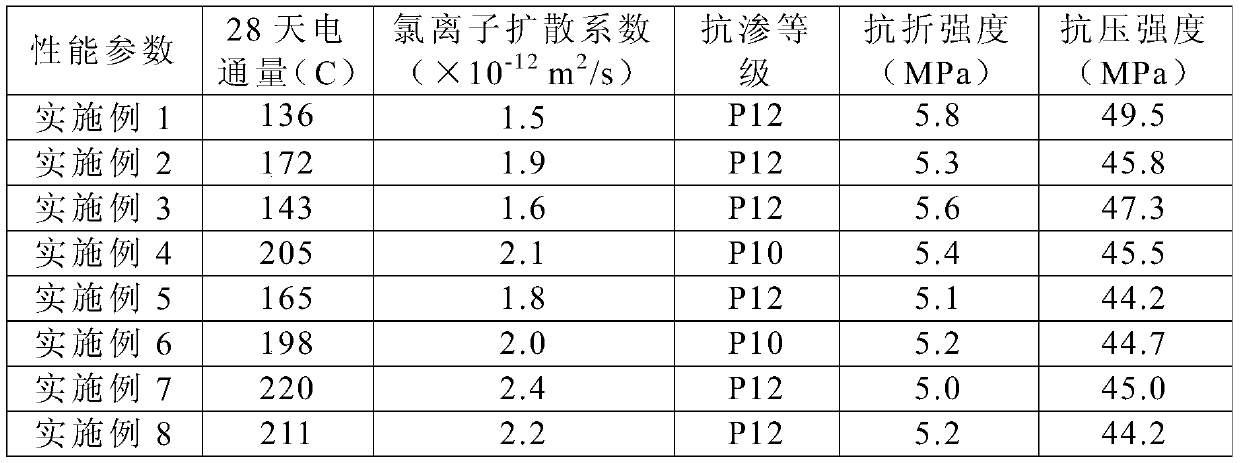

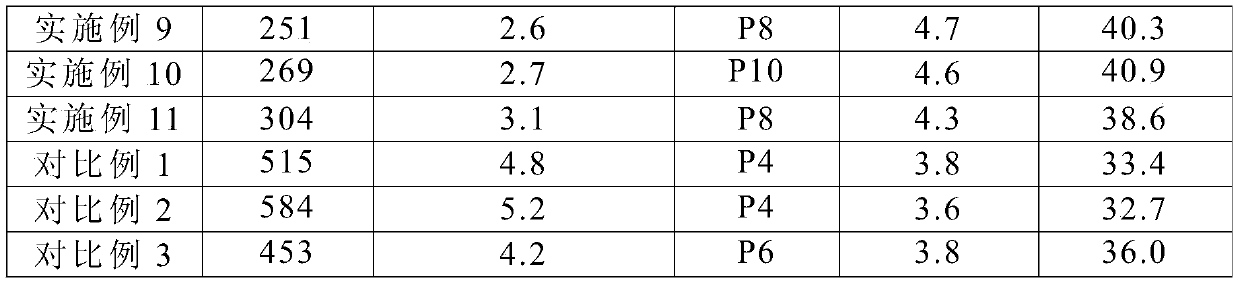

Examples

Embodiment 1

[0030] A kind of concrete resistant to chloride ion penetration. The raw materials include the following components in parts by weight: 260 parts of cement, 70 parts of fly ash, 60 parts of mineral powder, 680 parts of yellow sand, 1080 parts of crushed stone, 150 parts of water, and silica fume 20 parts, 7 parts of water reducing agent, 10 parts of compacting agent; 2 The mass percentage is 99wt%, Al 2 o 3 The mass percentage is 0.5wt%, and the specific surface area is 25000-28000m 2 / kg; the compacting agent is a mixture of 20wt% nano cerium oxide, 20wt% nano magnesia, and 60wt% zirconium dioxide; the water reducer is a mixture of polycarboxylate, casein, acrylic acid, The mass ratio is 3:2:1.

[0031] The concrete in this example is prepared by the following method: first add yellow sand and part of the crushed stone to the mixer for mixing, then add cement, fly ash, mineral powder, compacting agent, microsilica fume and mix together, then add water and water reducer to ...

Embodiment 2

[0034] A kind of concrete resistant to chloride ion penetration. The raw materials include the following components in parts by weight: 260 parts of cement, 70 parts of fly ash, 60 parts of mineral powder, 680 parts of yellow sand, 1080 parts of crushed stone, 150 parts of water, and silica fume 20 parts, 7 parts of water reducing agent, 10 parts of compacting agent; 2 The mass percentage is 96wt%, Al 2 o 3 The mass percentage is 2wt%, and the specific surface area is 25000-28000m 2 / kg; the compacting agent is a mixture of 30wt% nano cerium oxide, 10wt% nano magnesia, 60wt% zirconium dioxide; the water reducer is a mixture of polycarboxylate, casein, acrylic acid, The mass ratio is 3:2:1.

[0035] The concrete in this example is prepared by the following method: first add yellow sand and part of the crushed stone to the mixer for mixing, then add cement, fly ash, mineral powder, compacting agent, microsilica fume and mix together, then add water and water reducer to contin...

Embodiment 3

[0038] A kind of concrete resistant to chloride ion penetration. The raw materials include the following components in parts by weight: 260 parts of cement, 70 parts of fly ash, 60 parts of mineral powder, 680 parts of yellow sand, 1080 parts of crushed stone, 150 parts of water, and silica fume 20 parts, 7 parts of water reducing agent, 10 parts of compacting agent; 2 The mass percentage is 98wt%, Al 2 o 3 The mass percentage is 0.5wt%, and the specific surface area is 25000-28000m 2 / kg; the compacting agent is a mixture of 20wt% nano cerium oxide, 10wt% nano magnesia, 70wt% zirconium dioxide; the water reducer is a mixture of polycarboxylate, casein, acrylic acid, The mass ratio is 3:2:1.

[0039] The concrete in this example is prepared by the following method: first add yellow sand and part of the crushed stone to the mixer for mixing, then add cement, fly ash, mineral powder, compacting agent, microsilica fume and mix together, then add water and water reducer to cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com