Composite graphene high-strength construction waste cement mortar and preparation method thereof

A composite graphene and construction waste technology, which is applied in the field of composite graphene high-strength construction waste cement mortar and its preparation, can solve the problem of difficult use of recycled fine aggregate for concrete, construction waste utilization rate less than 5%, and high apparent density of components, etc. problem, to achieve the effect of reducing frictional resistance, reducing the amount of water, and densely distributed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

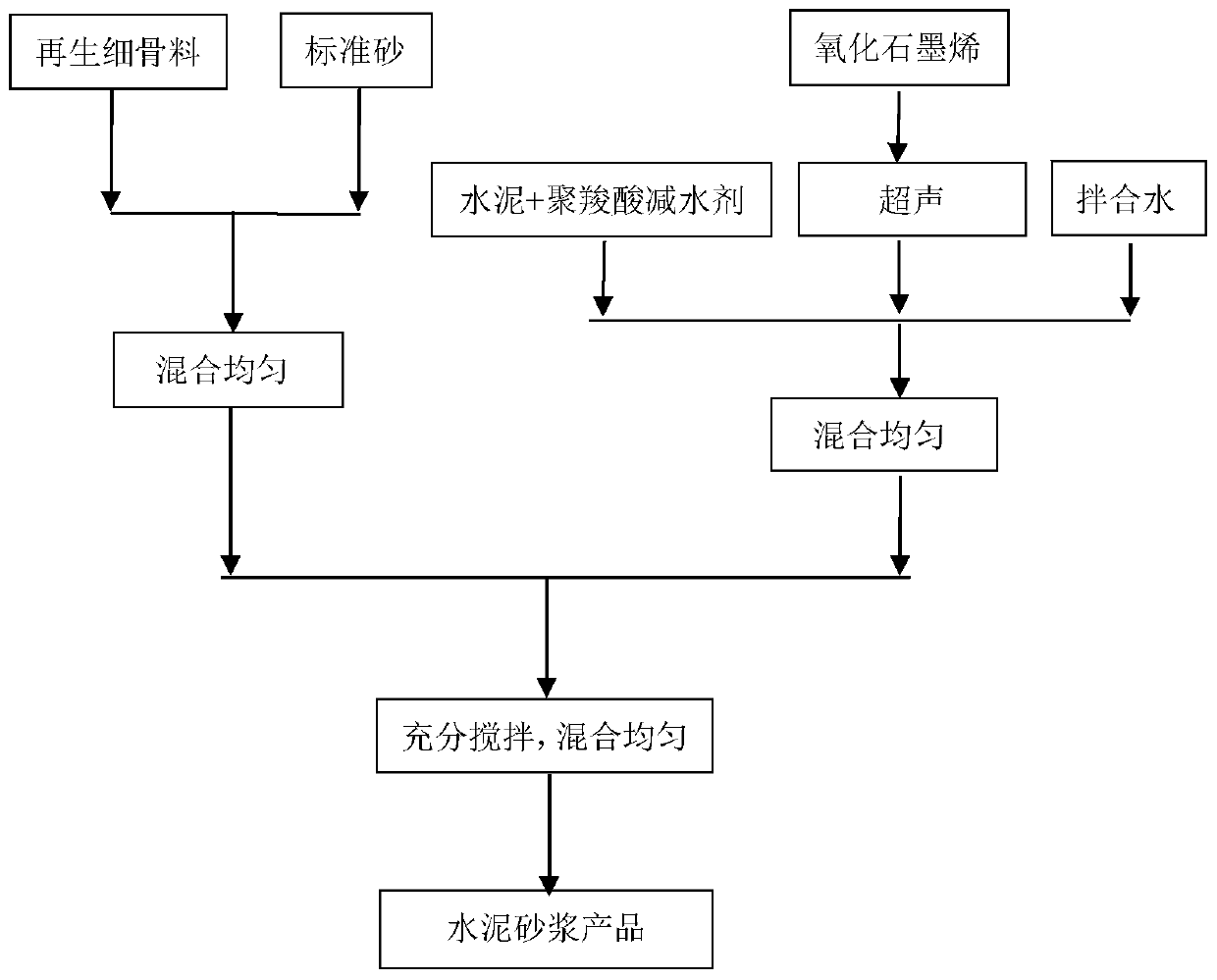

Method used

Image

Examples

Embodiment 1

[0033] The invention adopts construction waste as a raw material, crushes it with a roller crusher, and screens fine particles between 10 mesh and 60 mesh as regenerated fine aggregate, so as to realize resource recycling and turn waste into treasure. The physical properties of the obtained recycled fine aggregate are shown in Table 1.

[0034] Table 1

[0035]

[0036] The physical and chemical properties of graphene oxide GO used in this example are shown in Table 2.

[0037] Table 2

[0038]

[0039] The proportioning of each raw material of the present embodiment composite graphene high-strength construction waste cement mortar is by weight:

[0040] 12 parts of mixing water;

[0041] 22 parts of 42.5 grade ordinary Portland cement;

[0042] 19.8 parts of recycled fine aggregate;

[0043] 46.2 parts of standard sand;

[0044] Graphene oxide is 0.02% of the total amount of cement;

[0045] The polycarboxylate water reducer is 0.02% of the total amount of cement...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com