Multi-scale structure alloy material, preparation method and application thereof

An alloy material, multi-scale technology, applied in the field of multi-scale structure alloy material preparation, can solve the problems of difficulty in preparing high-density high-performance alloy materials, uncontrollable solid-liquid phase volume fraction ratio, and difficulty in preparing semi-solid slurry, etc. Achieve the effect of excellent comprehensive performance, integration of processing and heat treatment, improvement of internal quality and comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

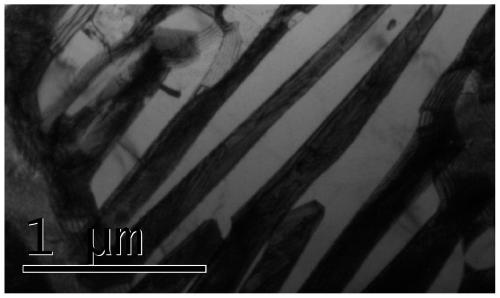

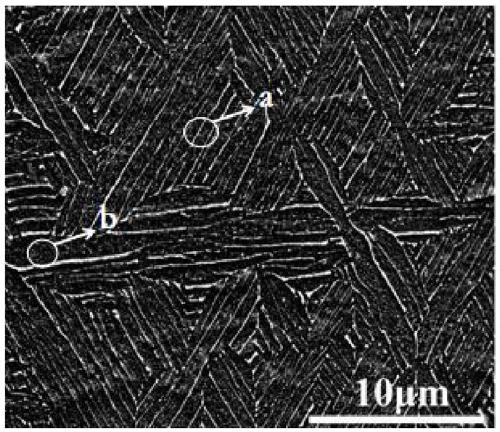

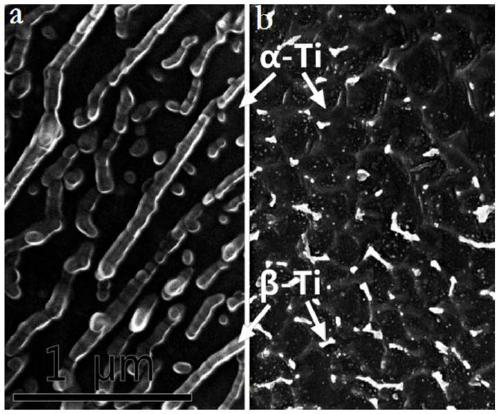

Image

Examples

Embodiment 1

[0046] The preparation method based on the alloy material in situ refinement grain of the present invention comprises the following steps:

[0047] (1) Densification and sintering of alloy powder: Weigh 20g of Ti-6Al-4V atomized alloy powder, put it into a graphite mold with a diameter of φ20mm and H50mm, pre-press with a pressure of 20MPa, and then put it into spark plasma sintering In the furnace cavity of the system, the sintering equipment: SPS-3.20MK-IV spark plasma sintering system; apply and maintain a sintering pressure of 30MPa through the upper and lower electrode plates, vacuumize to 10-2Pa, and then fill it with high-purity argon for protection. Pulse current rapid sintering, the process conditions are as follows:

[0048] Sintering method: pulse current;

[0049] Duty ratio of pulse current: 12:2;

[0050] Sintering pressure: 30MPa;

[0051] Heating rate: 100K / min;

[0052] Sintering temperature Ts: 1100°C;

[0053] Among them, the starting temperature of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com