Water loss protection structure for circulating fluidized bed boiler

A technology of circulating fluidized bed and protective structure, applied in steam boilers, steam boiler accessories, steam boiler components, etc., can solve problems such as high maintenance costs and loss of water supply, and achieve extended life, reduced waste, and a wide range of applications. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

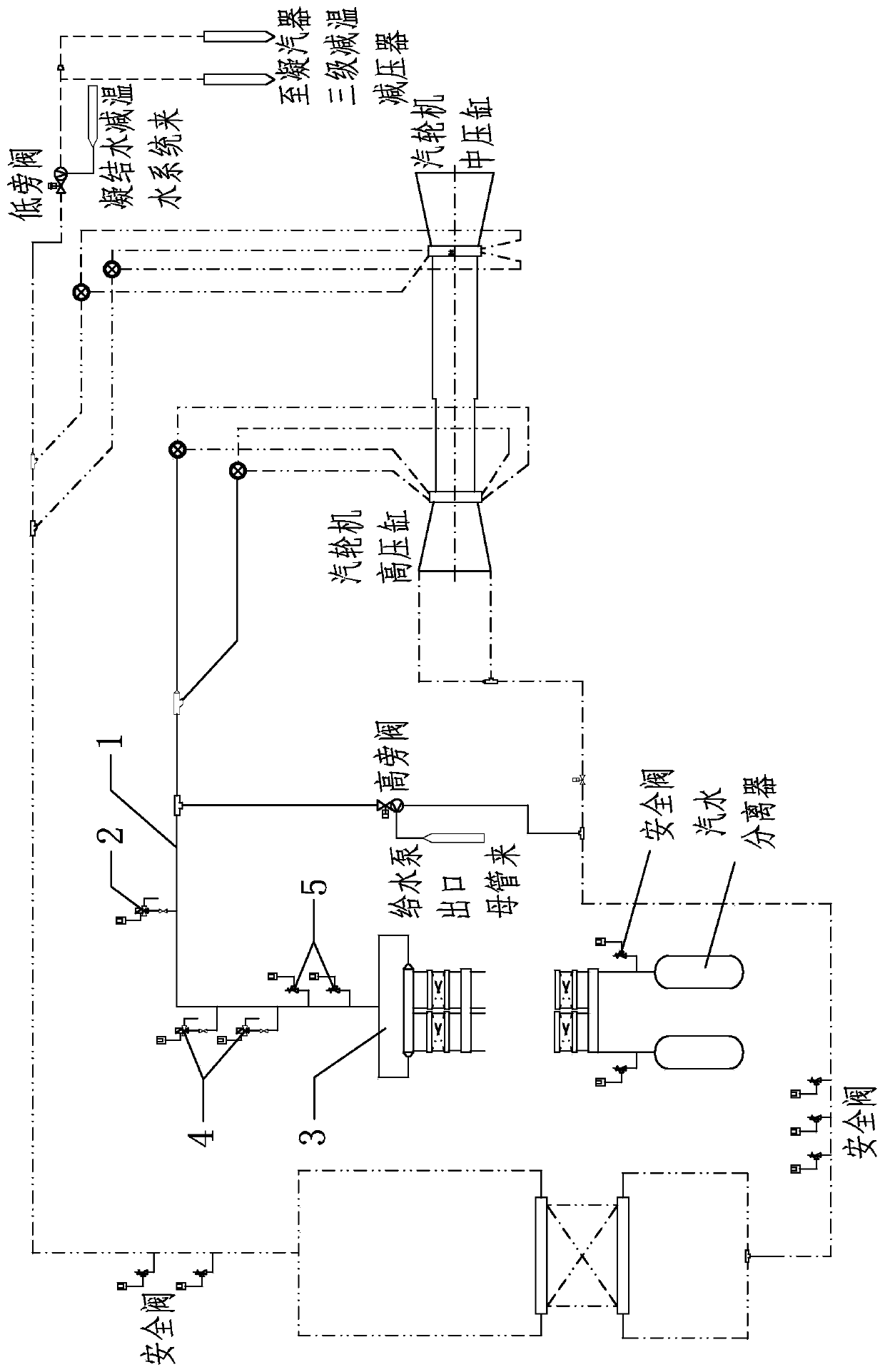

[0020] After the superheater 3 (or water-cooled wall) of the boiler is the outlet pipeline 1 of the superheater, and a safety valve and a PCV valve are arranged on the outlet pipeline 1 . After the loss of water accident, the steam pressure rises, and the PCV valve and safety valve will quickly take off after reaching the take-off pressure to discharge the steam. When the steam pressure falls back to the set reseating pressure, the PCV valve and safety valve are reseated.

[0021] Since the PCV valve and safety valve are set to protect the superheater, their capacity and take-off pressure are also selected according to the safety principle of protecting the superheater, and the parameter settings of the PCV valve and safety valve are stipulated by national standards and cannot be changed at will. Therefore, the arrangement of the existing valve body cannot discharge the steam in the heating surface at an optimal discharge rate so as to protect the heating surface.

[0022] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com