Optical fiber sensor based on graphene-based composite structure and preparation method thereof

A fiber optic sensor and composite structure technology, applied in the direction of instruments, optics, light guides, etc., can solve the problems of limited adsorption capacity, achieve the effects of increased sensitivity, faster resistance change rate, and enhanced exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

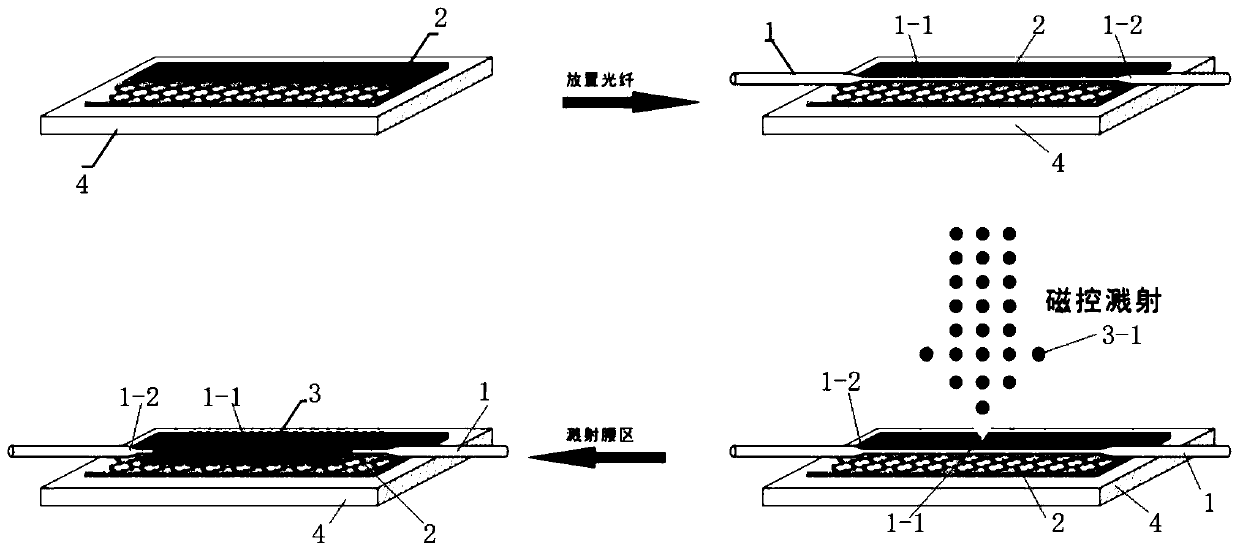

[0032] refer to image 3 , the present invention is based on the preparation method of graphene-based composite structure optical fiber sensor, comprises the steps:

[0033] S1, preparing a graphene substrate, forming a graphene film 2 on the upper surface of the glass slide 4;

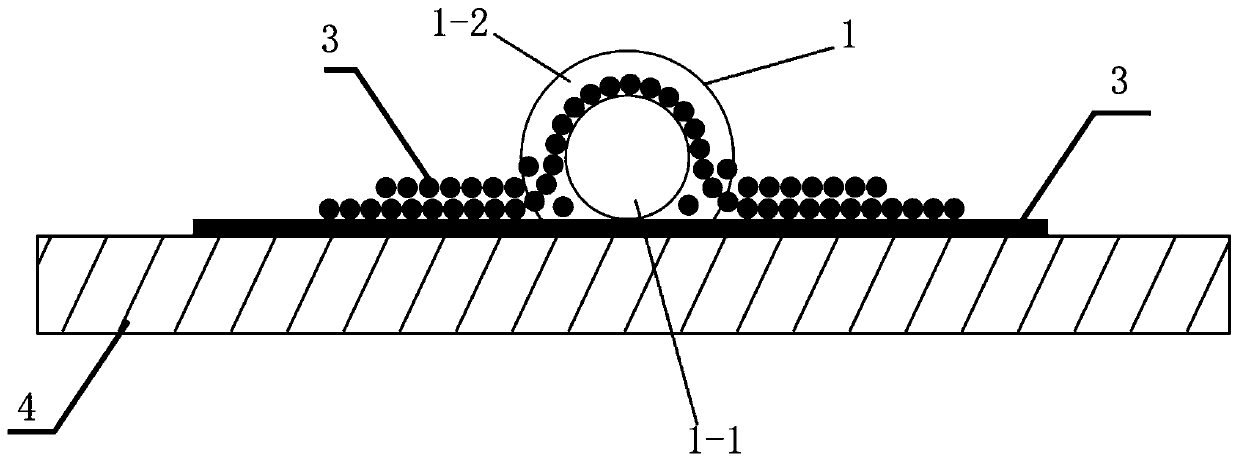

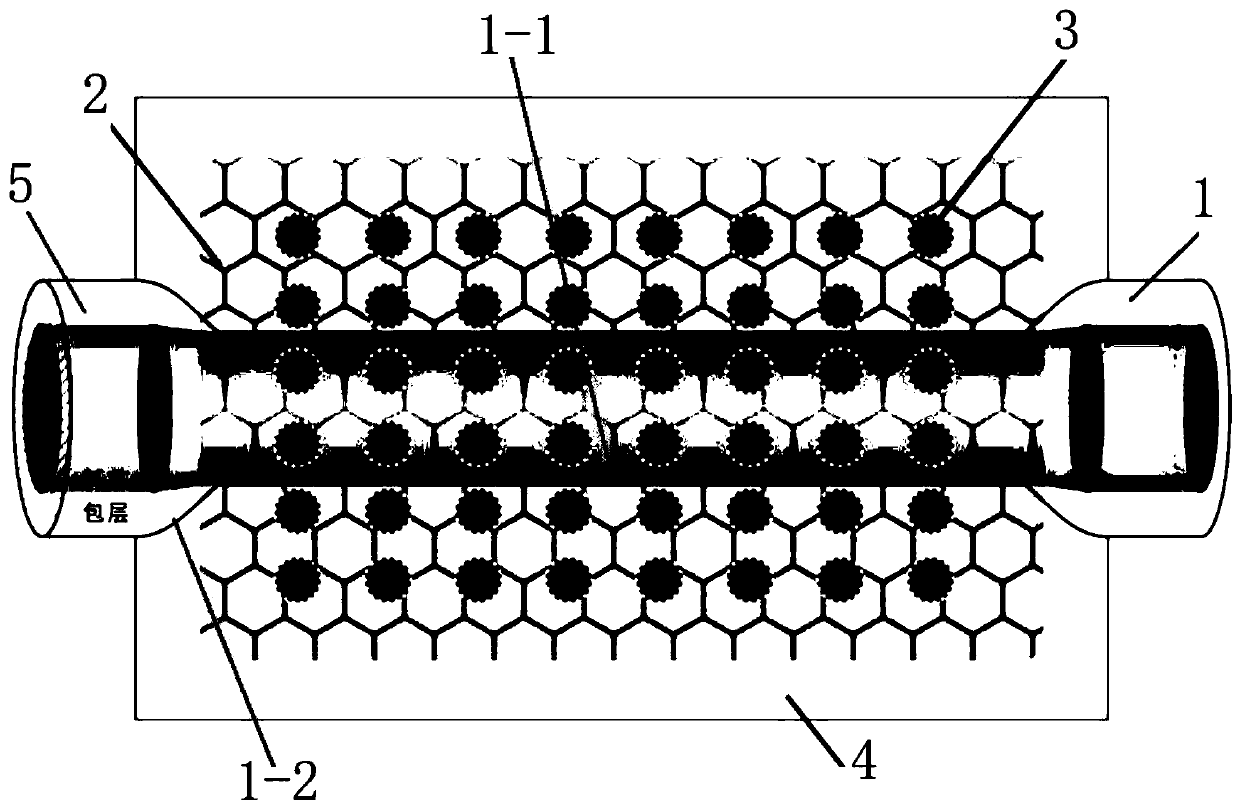

[0034] S2, the sensor body structure 1 is obtained by using the fusion tapering method, and the waist region 1-1 of the sensor body structure 1 is in the micro-nano scale;

[0035] S3, placing the waist region 1-1 of the sensor body structure 1 on the surface of the graphene substrate; using the magnetron sputtering method, sputtering metal oxide on the exposed surface of the waist region 1-1 and the surface of the graphene substrate, The bare surface of the region 1-1 and the surface of the graphene substrate form a metal oxide film 3 with gas-sensing properties, and the waist region 1-1 and the graphene substrate are bonded together through the metal oxide film 3 to form a sensing region.

[0036]...

Embodiment

[0051] like image 3 As shown, the preparation method of the present embodiment based on the graphene-based composite structure optical fiber sensor comprises the following steps:

[0052] (a) graphene film 2 is placed on the surface of slide glass 4;

[0053] (b) The waist region 1-1 of the transfer sensor body structure 1 is placed flat on the top of the graphene film 2;

[0054] (c) by WO 3 For the target sputtering waist region 1-1, WO 3 The particles are sputtered on the exposed surface of the waist region and the surface of the graphene film 2, and form WO 3 Nanofilm, WO 3 The nano-film bonded the waist region 1-1 and the graphene film 2 to obtain graphene and WO 3 A light sensor with a composite structure, that is, a fiber sensor based on a graphene-based composite structure of the present invention.

[0055] The following is the detailed structure and characteristics of each step:

[0056] Preparation of graphene paper substrate by vacuum filtration technology ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com