Trigger and protection circuit of excimer laser high-voltage switch

An excimer laser, high-voltage switch technology, applied in emergency protection circuit devices, phonon exciters, circuits, etc., can solve problems such as interference and damage to trigger circuits, and achieve the effect of reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

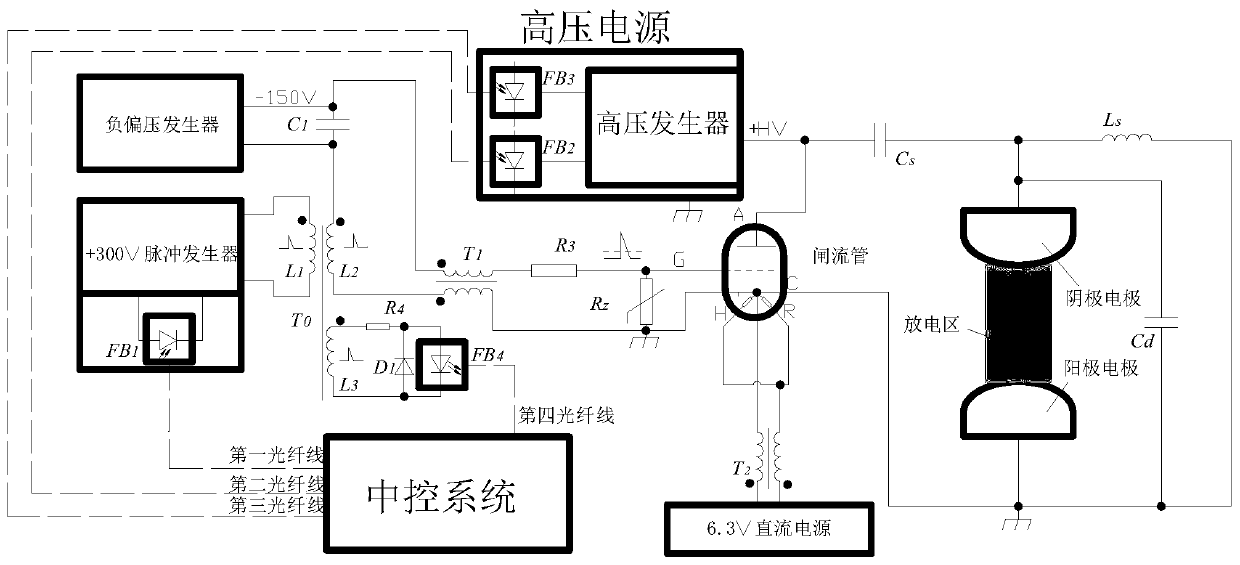

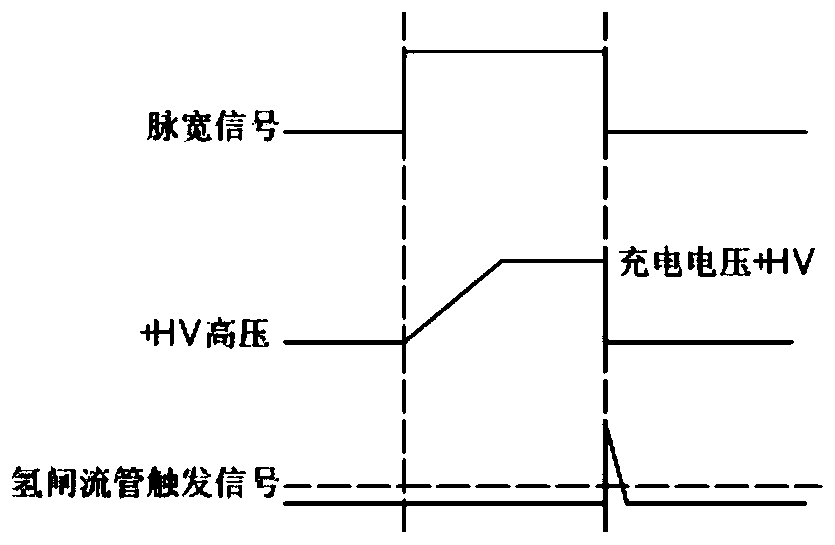

[0066] Embodiment 1. The high-voltage switch is a trigger and protection circuit of a hydrogen thyratron

[0067] Depend on figure 1 As shown, the circuit includes: central control system, high voltage generator, pulse generator, negative bias generator, hydrogen thyratron, capacitor C 1 , Transformer T 0 , Divider resistance R 4 , Diode D 1 , common mode choke coil T 1 , current limiting resistor R 3 , Varistor R Z , common mode choke coil T 2 , inductance L S , discharge capacitor C d , Energy storage capacitor C S , cathode electrode, anode electrode, fiber optic head FB 1 , Fiber head FB 2 , Fiber head FB 3 , Fiber head FB 4 ,DC power supply.

[0068] The central control system generates an optical pulse width signal and a charging reference voltage optical signal; the optical pulse width signal is used to indicate the time of light; the charging reference voltage optical signal is used to indicate the magnitude of the final charging voltage.

[0069] The ce...

Embodiment 2

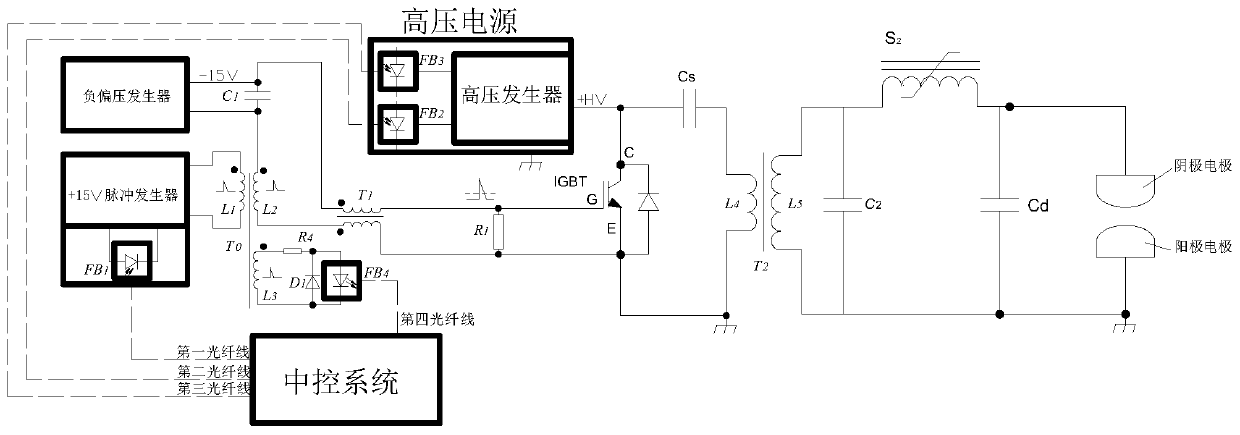

[0108] Embodiment 2, the high-voltage switch is an IGBT, that is, a trigger and protection circuit of an insulated gate bipolar transistor

[0109] Depend on image 3 As shown, the circuit includes: central control system, pulse generator, negative bias generator, high voltage generator, IGBT, capacitor C 1 , Transformer T 0 , Divider resistance R 4 , Diode D 1 , common mode choke coil T 1 , Snubber resistance R 1 , Transformer T 2 , Energy storage capacitor C S , Voltage doubling capacitor C 2 , discharge capacitor C d , cathode electrode, anode electrode, fiber optic head FB 1 , Fiber head FB 2 , Fiber head FB 3 , Fiber head FB 4 , magnetic switch S 2 .

[0110] The central control system generates an optical pulse width signal and a charging reference voltage optical signal; the optical pulse width signal is used to indicate the time of light; the charging reference voltage optical signal is used to indicate the magnitude of the final charging voltage.

[011...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com