Moulded tablet based on 3D printing mold and prepared from photo-curing material

A light-curing material, 3D printing technology, applied in additive processing, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc. Rate-adjustable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1. Ibuprofen molded tablet

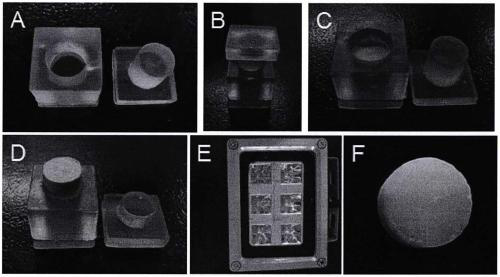

[0024] Step 1, establishment and printing of ibuprofen mold impression sheet mold model: use 3D modeling software to set up a circular ibuprofen impression sheet mold model complementary to the shape of ibuprofen impression sheet, consisting of the middle part of the mold, the base and its Press the cover to form and save it as an STL format file; input the STL file into the slicing software, obtain the slicing file, and transfer it to the photocuring method for 3D printing, and use the photosensitive resin as the material to print the ibuprofen mold. After the mold is printed, use The residual liquid photosensitive resin on the mold surface is rinsed with absolute ethanol, and dried to obtain the ibuprofen impression sheet mold;

[0025] Step 2. Preparation of ibuprofen molded tablets: Weigh 93 parts of ibuprofen and 7 parts of N-vinylpyrrolidone containing Irgacure 2959 in parts by weight, mix well, fully stir until completely m...

experiment example 1

[0030] Experimental example 1. Mold printing method

[0031] Step 1. Use 3D modeling software to build a circular model of the middle part of the mold that is complementary to the shape of the mold, and save it as an STL file; input the STL file into the slicing software, and after obtaining the slicing file, transfer it to the photocuring 3D Printing, using photosensitive resin as the material to print candy molds, after the mold is printed, rinse the residual liquid photosensitive resin on the surface of the mold with absolute ethanol, and obtain the stamped sheet mold after drying;

[0032] Step 2: Use 3D modeling software to build a model of the middle part of the circular mold that is complementary to the shape of the mold and save it as an STL file; use the STL file to print with polylactic acid PLA on the fused deposition method 3D printing to obtain the mold piece mold;

[0033] Step 3: Stick the mold printed with SLA and FDM on the conductive tape, spray gold on the su...

experiment example 2

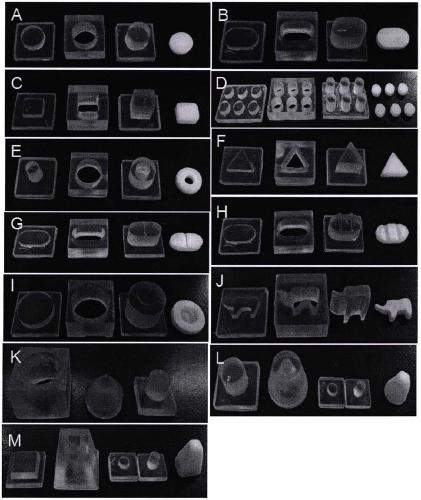

[0035] Experimental Example 2. Advantages of Ibuprofen Imprinted Tablets Compared with Common Compressed Tablets

[0036] According to Example 1, molded tablets of various shapes can be prepared. When special groups such as the elderly or children take medicine, the cartoon pattern can reduce children’s fear of taking medicine, and the tablet conforming to ergonomics can reduce the swallowing of medicine by the elderly. difficult question. The in vitro release experiment shows that the imprinted tablet has a longer release time than the compressed tablet and has a sustained release effect, which can reduce the side effects caused by the sudden release of the drug. The long-term release of the ibuprofen imprinted tablet can continue to play a role and reduce the patient's medication. times. In addition, compared with compressed tablets, molded tablets use very few excipients, which can reduce the toxic and side effects caused by excipients and improve the incompatibility of dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com