Improved low-toxicity high-efficiency orthoester miscible substance pharmaceutical adjuvant, preparation method and local sustained-release drug delivery preparation containing adjuvant

A technology of pharmaceutical excipients and ortho esters, which is applied to medical preparations with non-active ingredients, medical preparations containing active ingredients, and pharmaceutical formulas, etc., can solve problems such as damage to respiratory mucosa, vision, damage, and blindness, and achieve Improve the therapeutic index and compliance, the value of extensive clinical application, the effect of slow and uniform treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

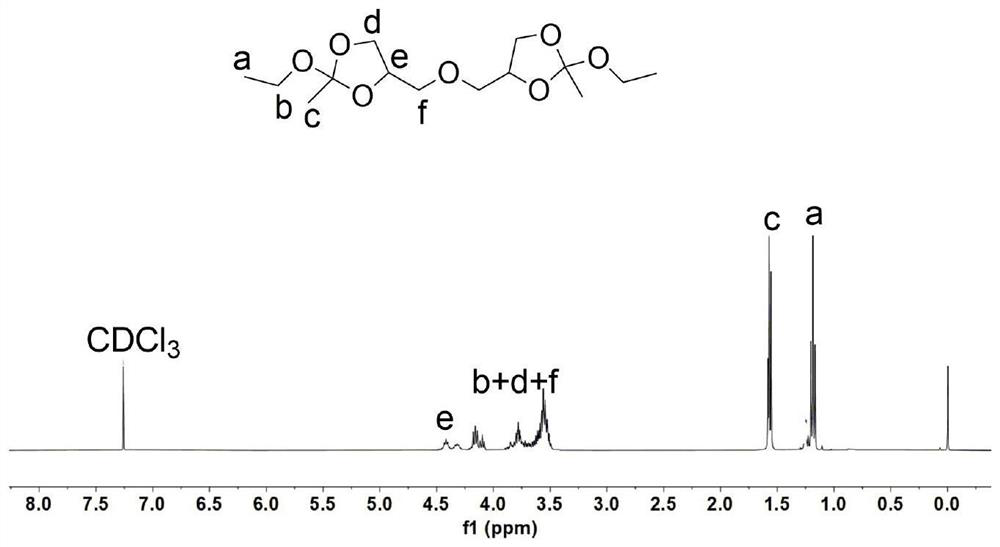

[0079] Synthesis of orthoester compound 4,4'-(oxybis(methylene))bis(2-ethoxy-1,3-dioxolane)(OE-1')

[0080] Under nitrogen protection, diglycerol (16.6 g, 0.1 mol), triethyl orthoacetate (48.67 g, 0.3 mol) and p-toluenesulfonic acid (344.4 mg, 0.002 mol) were added to the reaction flask, and acetonitrile (150 mL) was added. ) was dissolved and reacted at room temperature overnight. After the acetonitrile was removed by distillation under reduced pressure, the crude product was dissolved in ethyl acetate, extracted with saturated sodium carbonate solution, dried over anhydrous magnesium sulfate, and distilled under reduced pressure to remove ethyl acetate and excess triethyl orthoacetate to obtain a colorless oily product. rate of 78.4%, 1 HNMR as figure 1 shown.

Embodiment 2

[0082] Synthesis of orthoester compound 4,4'-(oxybis(methylene))bis(2-propoxy-1,3-dioxolane)(OE-2')

[0083] Under nitrogen protection, diglycerol (16.6 g, 0.1 mol), tripropyl orthoacetate (61.25 g, 0.3 mol) and p-toluenesulfonic acid (344.4 mg, 0.002 mol) were added to the reaction flask, and acetonitrile (150 mL) was added. ) was dissolved and reacted at room temperature overnight. After the acetonitrile was removed by distillation under reduced pressure, the crude product was dissolved in ethyl acetate, extracted with saturated sodium carbonate solution, dried over anhydrous magnesium sulfate, and distilled under reduced pressure to remove ethyl acetate and excess triethyl orthoacetate to obtain a colorless oily product. The rate was 76.2%.

Embodiment 3

[0085] Orthoester compound 4,4'-(oxybis(methylene))bis(2-(2-methoxymonomethyl ether polyethylene glycol)-1,3-dioxolane)(OE -3') synthesis

[0086] OE-1' (30.6g, 0.1mol), polyethylene glycol 550 monomethyl ether (165.0g, 0.3mol) and pyridine p-toluenesulfonate (502.6mg, 0.002mol) were added to the reaction flask, and at 135 The reaction was carried out under reduced pressure for 4 hours. The crude product was purified by dialysis using tetrahydrofuran containing a trace amount of triethylamine, the molecular weight cut-off of the used dialysis bag was 1000 Daltons, and the yield was 84.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com