Light hydrocarbon oil gas recovery system carrying associated gas

An oil and gas recovery system and associated gas technology, applied in the direction of steam condensation, chemical instruments and methods, separation methods, etc., can solve the problems of dispersed and small amount of associated gas, economic loss, good volatility, etc., to reduce unsafe factors, The effect of increasing economic benefits and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

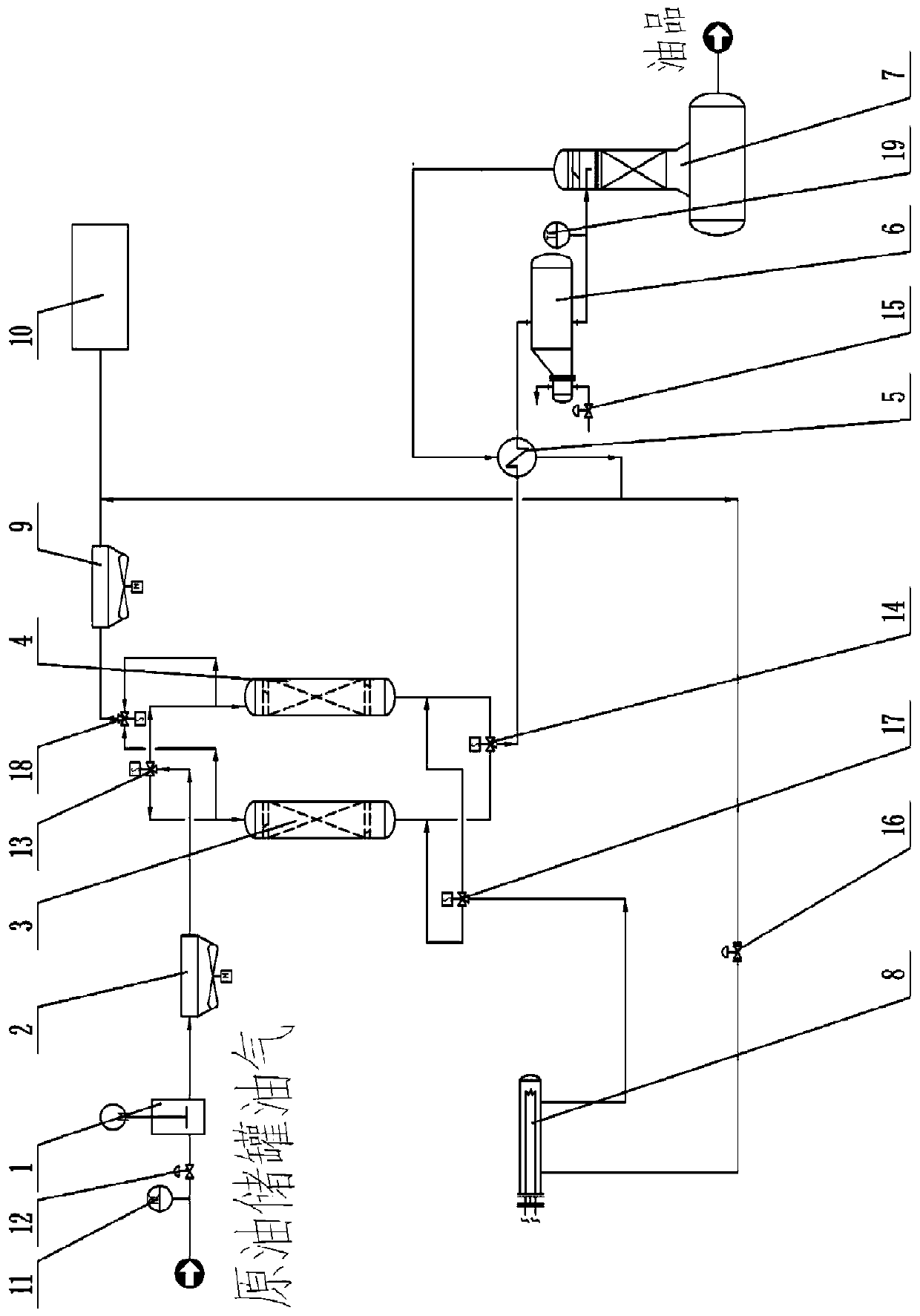

[0015] A light hydrocarbon oil and gas recovery system carrying associated gas, including raw gas compressor 1, air cooler 2, molecular sieve tower A3 and molecular sieve tower B4, precooler 5, evaporator 6, deethanizer 7, crude oil storage tank volatilization The oil and gas coming out are transported through the pipeline to the raw material gas compressor 1 for pressurization, the raw material gas compressor 1 is connected to the air cooler 2 through the pipeline, and the air cooler 2 is divided into two branch pipelines through the pipeline, and the two branch pipelines are respectively connected to the molecular sieve tower A3 and The air inlet of molecular sieve tower B4, the gas outlets of molecular sieve tower A3 and molecular sieve tower B4 are connected to precooler 5 through pipelines, precooler 5 is connected to evaporator 6 through pipelines, and the condensation outlet of evaporator 6 is connected to deethylation through pipelines The air inlet of the alkane tower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com