Metal coil splitting machine

A technology of metal coils and slitting machines, which is applied to metal processing machinery parts, metal processing equipment, shearing devices, etc., to achieve the effects of reducing work load, delaying wear, and solving quality defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

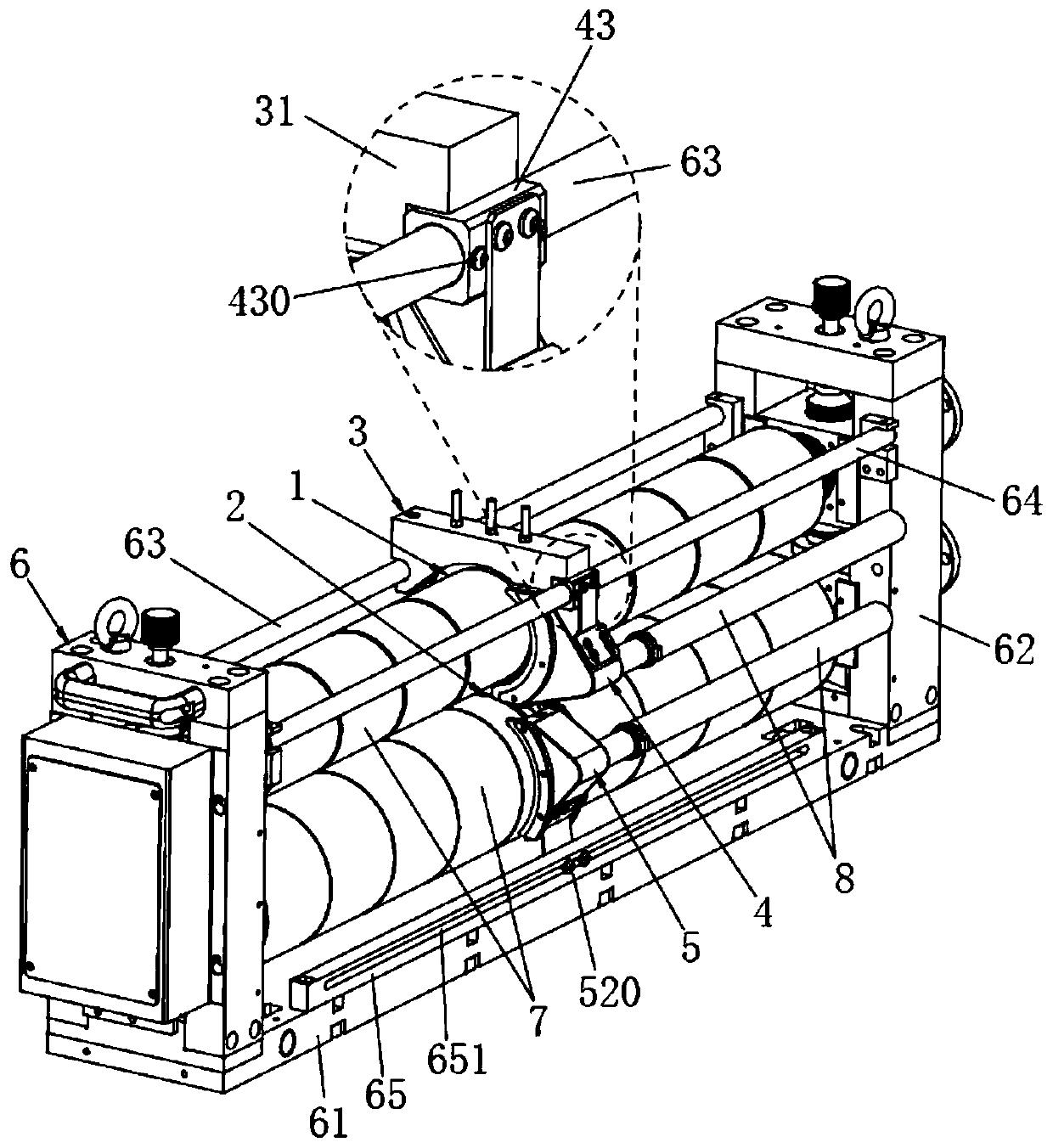

[0042] Such as figure 1 As shown in , the traditional battery pole piece slitting machine includes an upper shaft and a lower shaft arranged in parallel up and down. And two columns 62 that are vertically arranged on the base 61, the upper rotating shaft and the lower rotating shaft are horizontally arranged between the two columns 62; Knife 2 and two splitting knives are fixed on the rotating shaft through the spacer 7. It is understandable that the upper splitting knife 1 and the lower splitting knife 2 can be fixed on the two rotating shafts by using the hydraulic locking knife seat instead of the spacer 7. Above, the upper slitting knife 1 and the lower slitting knife 2 are co-located up and down, and the battery electrode coil to be slit is cut by the two slitting knives after passing between the upper slitting knife 1 and the lower slitting knife 2 cut apart.

[0043] During the use of this slitting machine, the upper cutting knife 1 wears too fast, resulting in a high...

Embodiment 2

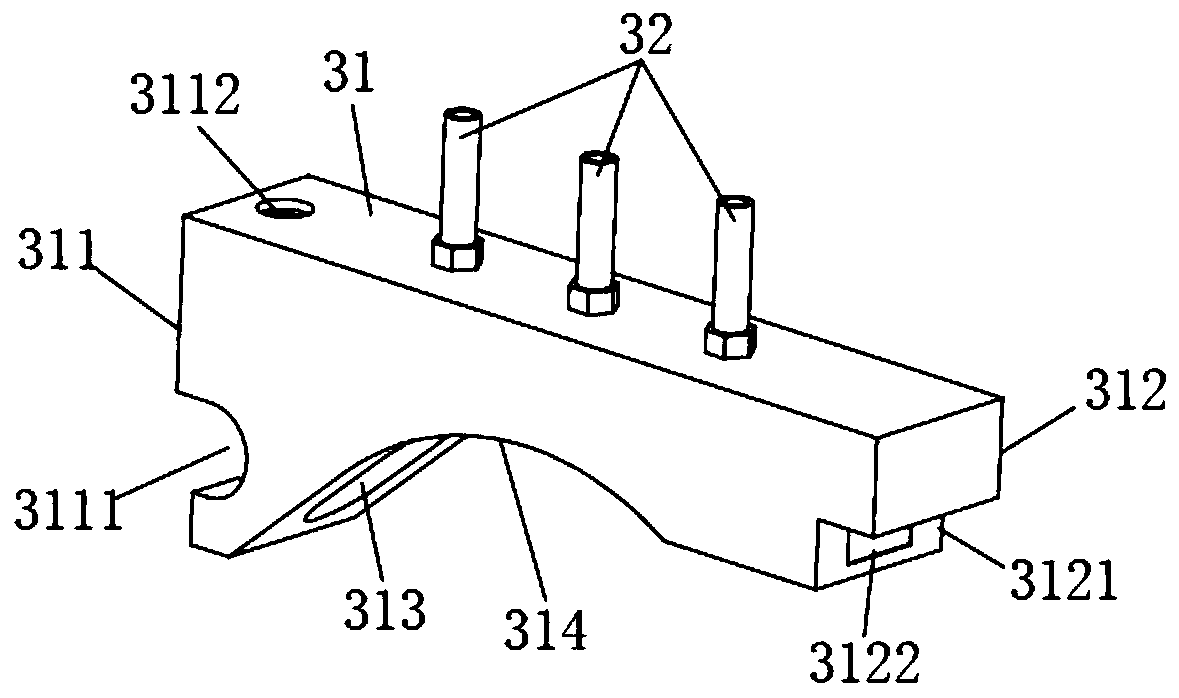

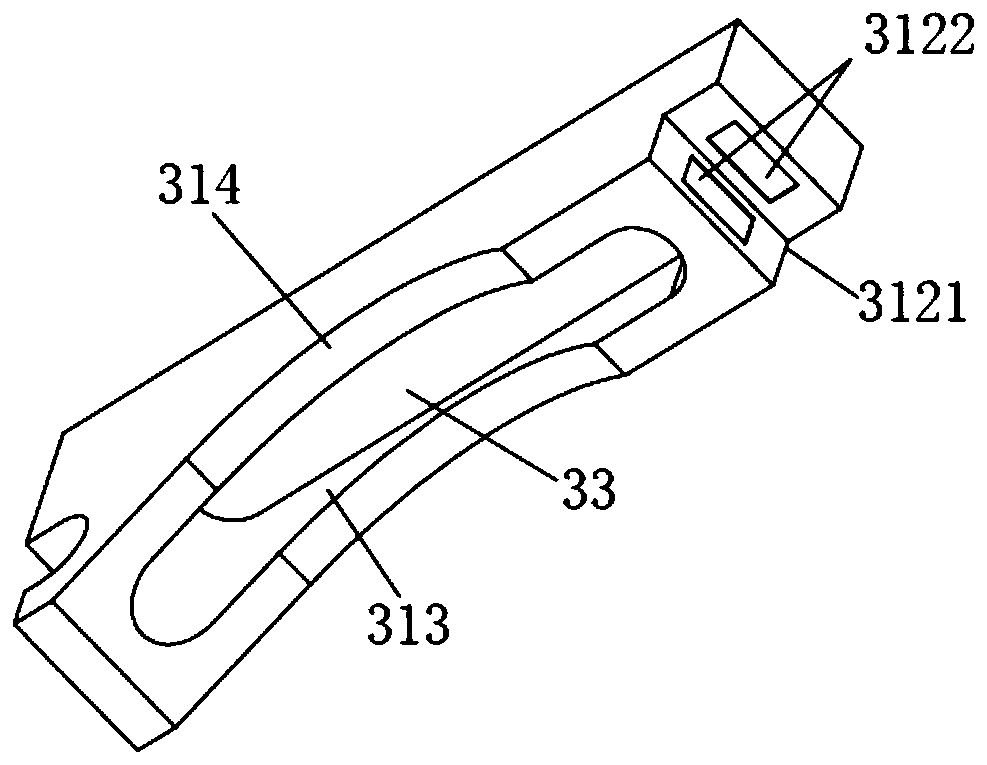

[0052] A kind of metal coil cutting machine of the present embodiment, basic structure is the same as embodiment 1, and difference and improvement are, as figure 2 with image 3 As shown in , the abutment 31 has a first connecting end 311 and a second connecting end 312, the first connecting end 311 has a side slot 3111, and the upper side of the abutment 31 is provided with a The fastening bolt I 3112 in the card slot 3111; the second connecting end 312 has a step bayonet 3121, and the inner side of the step bayonet 3121 is provided with a magnetic piece 3122, and the magnetic piece 3122 is preferably a permanent magnet alloy block .

[0053] During installation, the side clamping groove 3111 is clamped on the first crossbar 63, and the step bayonet 3121 is clamped on the second crossbar 64 at the same time, after the position is adjusted, tighten the fastening bolts I3112 fixes the first connecting end 311, and the second connecting end 312 is sucked and fixed on the seco...

Embodiment 3

[0055] A kind of metal coil slitting machine in the present embodiment, basic structure is the same as embodiment 2, and difference and improvement are, as figure 1 As shown in , it also includes an upper dust suction cover assembly 4, which is covered on the outside of the upper cutting knife 1; and a lower dust suction cover assembly 5, which is covered on the outside of the lower cutting knife 2; the upper dust suction The cover assembly 4 and the lower dust suction cover assembly 5 are used to absorb debris and dust generated by the slitting process. The upper dust suction hood assembly 4 and the lower dust suction hood assembly 5 are respectively connected to an external dust suction device through flexible connecting pipes 8 .

[0056] After the knife surface cleaning device 3 is installed on the slitting machine, although it can protect the upper slitting knife 1, the debris and dust generated by the slitting cannot be removed in time, resulting in a large amount of deb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com