Diamond dry particles, glazed brick with positioning diamond flashing effect and preparation method of glazed brick

A dry grain and diamond technology, applied in the positioning of diamond glazed glazed tiles and their preparation, in the field of diamond dry grains, can solve the problems of unrealistic ceramic tiles, dirty white tiles, and inability to achieve flashing effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

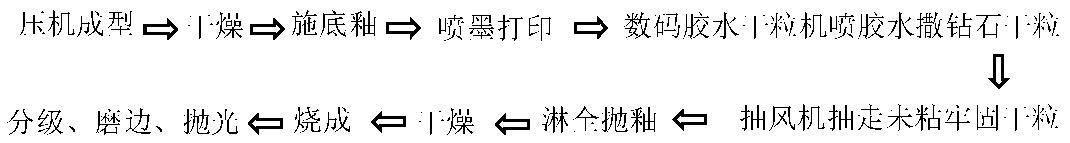

[0028] figure 1 The manufacturing flow of the ceramic tile of 1st Embodiment is shown. Such as figure 1 As shown, the green body is firstly prepared, and the green body can be formed from a common ceramic base material by a press.

[0029] The body can then be dried. The drying time can be 1-1.5 hours, and the moisture content of the dried billet can be controlled at 0.3-0.5%.

[0030] Then, base glaze is applied on the green body. The undercoat glaze is not particularly limited, and any undercoat glaze known in the art can be used. In some embodiments, the chemical composition of the primer can include: by mass percentage, SiO 2 : 55~60%, Al 2 o 3 : 21~24%, Fe 2 o 3 : 0.16~0.46%, TiO 2 : 0.15~0.25%, CaO: 0.1~0.3%, MgO: 0.1~0.3%, K 2 O: 4.0~5.0%, Na 2 O: 2.0~3.0%, ZrO 2 : 6.0~10.0%, loss on ignition: 3.0~4.0%.

[0031] The way of applying the bottom glaze can be spray glaze and so on. The specific gravity of the bottom glaze can be 1.40~1.45, and the glaze amoun...

Embodiment 1

[0044] (1) Weigh the following raw materials: kaolin 8%, albite 23%, potassium feldspar 13%, calcite 20%, alumina 8%, burnt talc 3%, zinc oxide 4%, selected zircon Sand (150 mesh to 250 mesh) 21%;

[0045] (2) The above raw materials are mixed, melted in a furnace at 1550°C, and water-quenched to obtain a transparent glass body.

[0046] (3) The transparent glass body is crushed and sieved into a certain particle size distribution to obtain dry diamond particles. The particle size of dry diamond particles is 60-80 mesh: 40%, 80-100 mesh: 30%, 100-150 mesh: 30%. The chemical composition of diamond dry particles is: SiO 2 : 48.06%, Al 2 o 3 : 17.32%, Fe 2 o 3 : 0.28%, TiO 2 : 0.18%, CaO: 11.10%, MgO: 1.07%, K 2 O: 1.87%, Na 2 O: 3.05%, ZnO: 3.88%, ZrO 2 : 12.69%, loss on ignition: 0.49%;

[0047] (4) Press dry pressing;

[0048] (5) Drying, the drying time is 1.2h, and the moisture content of the dried billet is 0.4%;

[0049] (6) Spray glaze, specific gravity 1.42,...

Embodiment 2

[0059] Weigh the following raw materials: kaolin 8%, albite 28%, potassium feldspar 13%, calcite 20%, alumina 6%, burnt talc 3%, zinc oxide 4%, selected zircon sand (150 mesh ~ 250 mesh) 18%.

[0060] (2) The above raw materials are mixed, melted in a furnace at 1550°C, and water-quenched to obtain a transparent glass body.

[0061] (3) The transparent glass body is crushed and sieved into a certain particle size distribution to obtain dry diamond particles. The particle size of dry diamond particles is 60-80 mesh: 40%, 80-100 mesh: 30%, 100-150 mesh: 30%. The chemical composition of diamond dry particles is: SiO 2 : 50.23%, Al 2 o 3 : 16.52%, Fe 2 o 3 : 0.30%, TiO 2 : 0.16%, CaO: 11.16%, MgO: 1.05%, K 2 O: 1.85%, Na 2 O: 3.58%, ZnO: 3.86%, ZrO 2 : 10.74%, loss on ignition: 0.45%;

[0062] (4) Press dry pressing;

[0063] (5) Drying, the drying time is 1.2h, and the moisture content of the dried billet is 0.4%;

[0064] (6) Spray glaze, specific gravity 1.42, glaz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com