Composition for automobile interior skin and manufacturing method thereof

A technology for automotive interiors and compositions, applied in vehicle components, chemical instruments and methods, vehicle safety arrangements, etc., to achieve the effects of excellent powder fluidity, excellent sensitivity characteristics, excellent light weight and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0109] Preparation Example: Production of Ether-Containing Polyester Polyol

[0110] A first mixture comprising 44 parts by weight of adipic acid, 20 parts by weight of 1,4-butanediol and 36 parts by weight of polytetramethylene ether diol having a hydroxyl value of 448.8 mgKOH / g was prepared. alcohol. The first mixture was heated from room temperature to a first heating temperature of 150° C., and then maintained at the first heating temperature for 60 minutes. Next, the first mixture was heated from the first heating temperature to a second heating temperature of 230° C., and kept at the second heating temperature for 30 minutes. Thereafter, while maintaining the second heating temperature, a vacuum degree of 720 mmHg was applied to the first mixture, and then the first mixture was reacted until the acid value of the first mixture reached 0.3 mgKOH / g or lower, thereby producing a product having 12.3 % condensed water content and 74.8 mgKOH / g hydroxyl value of ether-contain...

example 1 and example 2 and comparative example 1 to comparative example 6

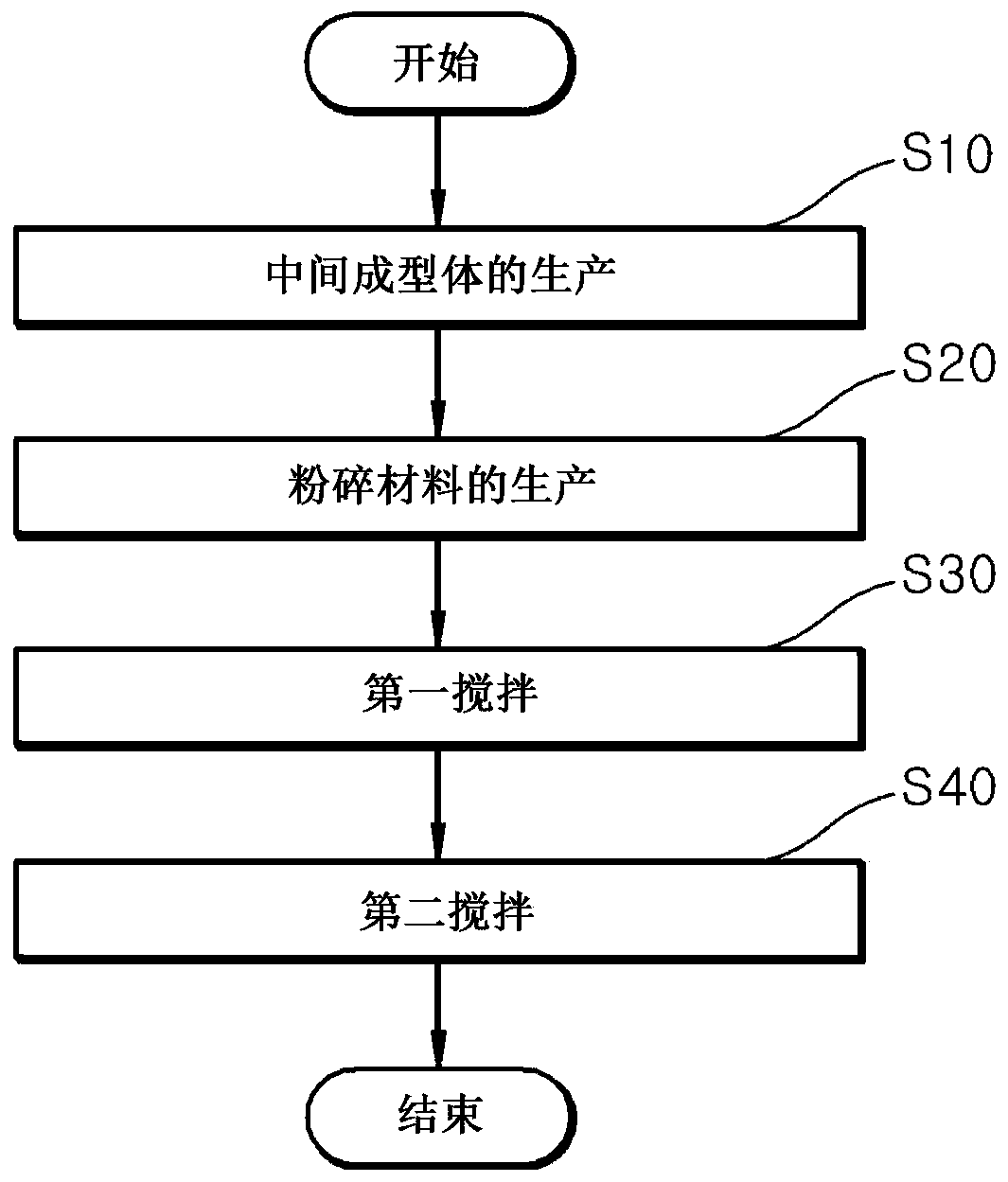

[0120] These components were introduced into an extruder according to the components and contents shown in Table 1 below, and then melted and kneaded. The kneaded material is water-cooled and cut to produce an intermediate shaped body in the form of pellets. Thereafter, the intermediate shaped body was dried and pulverized at -100°C, whereby a pulverized material was obtained. Next, the pulverized material is introduced into the thermal mixer, and the first stirring is performed at a blade rotation speed of 500 rpm to 1500 rpm and at a temperature of 80°C to 110°C. The stirred pulverized material is introduced into the cooling mixer, and second stirring is performed at a blade rotation speed of 200 rpm to 1000 rpm for 30 seconds to 300 seconds, thereby manufacturing a composition for an automobile interior skin in a powder form.

example 1 and example 2 and comparative example 1 to comparative example 7

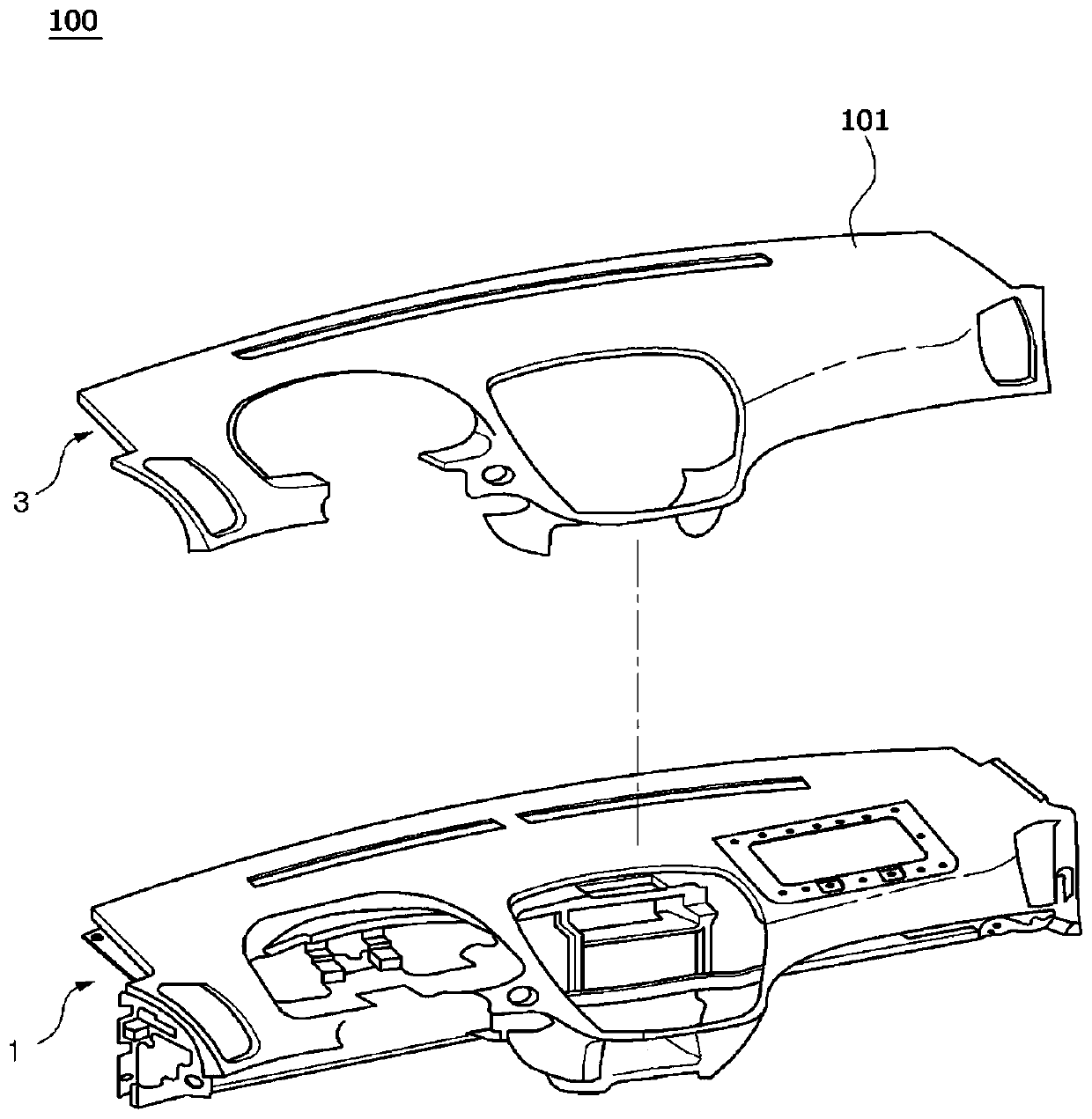

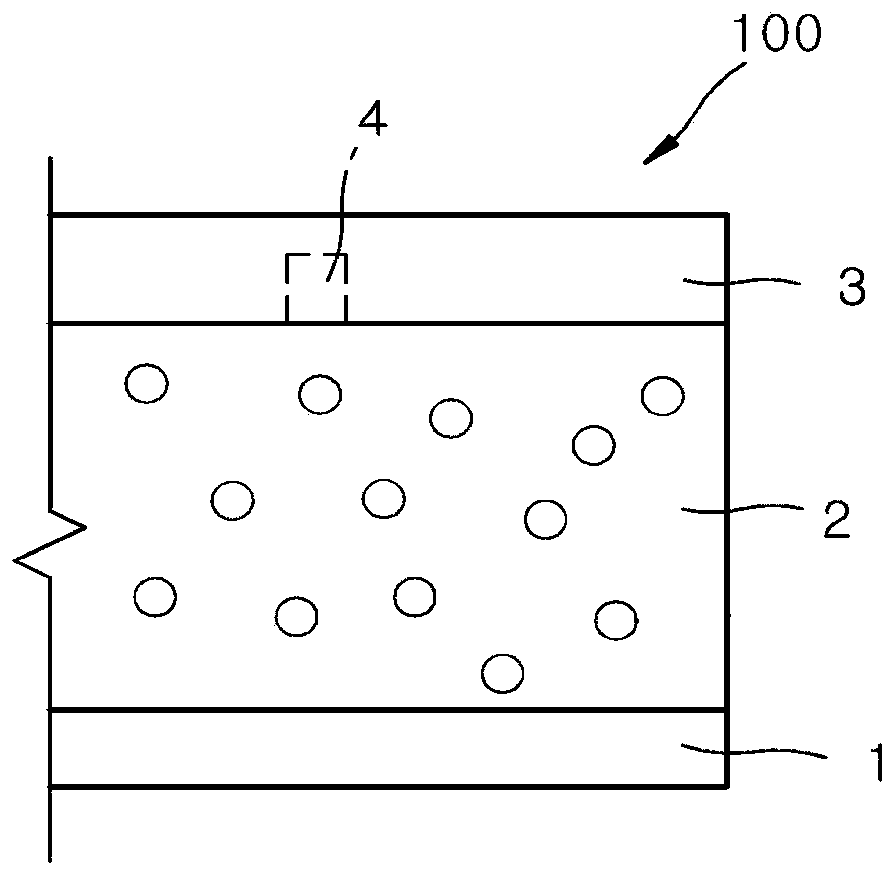

[0134] Prepare a 3mm to 4mm thick core layer comprising a matrix resin comprising a polypropylene-based resin, a styrene-diene based polymer and an inorganic filler, and form a 3mm to 5mm thick layer containing Foam layer of polyurethane foam. Then, the compositions for automotive interior skins produced in each of Examples 1 and 2 and Comparative Examples 1-7 were subjected to slip molding to form a 0.8 mm thick skin layer on the surface of the foam layer. At this time, the core layer and the skin layer are formed without undergoing the skin scoring process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| apparent density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com