Coiled tubing drilling fluid and method of use thereof

A technology for tubing and drilling plugs, which is applied in the field of coiled tubing drilling plugging fluids, can solve the problems of easy foaming of surfactants, low preparation concentration, and hindered entry, and achieves strong ability to carry drill cuttings and rubber, and easy operation in operating procedures. , The effect of simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051]A coiled tubing drilling fluid, consisting of coiled tubing drilling fluid A and coiled tubing drilling fluid B;

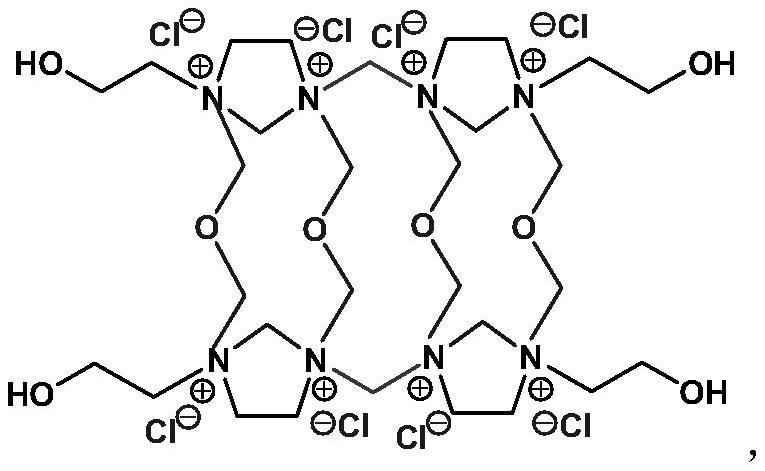

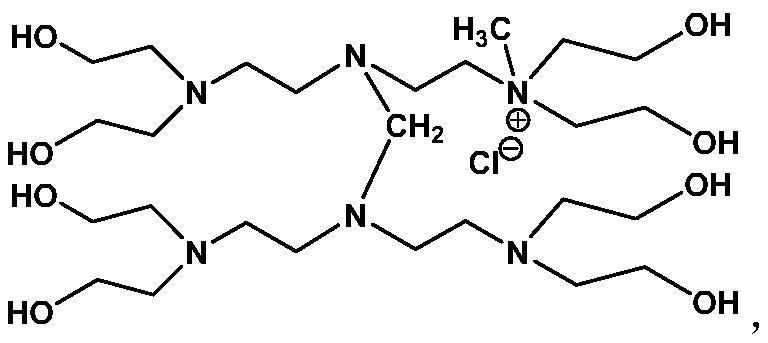

[0052] The preparation method of coiled tubing drilling plug fluid A is as follows: take 0.2 parts by weight of clay stabilizer and 0.3 parts by weight of friction reducer and dissolve them in 99.5 parts by weight of water, stir or circulate evenly to obtain 100 parts by weight of coiled tubing drilling plug Liquid A; Wherein, the clay stabilizer adopts the quaternary ammonium salt I with the following chemical structural formula:

[0053]

[0054] The antifriction agent is formed by mixing 5 parts by weight of Swire oil, 10 parts by weight of ethylene glycol, 15 parts by weight of isomeric tridecyl alcohol polyoxyethylene ether and 80 parts by weight of water;

[0055] The preparation method of coiled tubing drilling plug fluid B is as follows: take 0.3 parts by weight of drag reducer suspension and 0.2 parts by weight of clay stabilizer and dissolve the...

Embodiment 2

[0060] A coiled tubing drilling fluid, consisting of coiled tubing drilling fluid A and coiled tubing drilling fluid B;

[0061] The preparation method of coiled tubing drilling plug fluid A is as follows: 2 parts by weight of clay stabilizer and 5 parts of friction reducer are dissolved in 93 parts by weight of water, and stirred or circulated evenly to obtain 100 parts by weight of coiled tubing drilling plug Liquid A; wherein, the clay stabilizer adopts benzyl quaternary ammonium salt I with the following chemical structure:

[0062]

[0063] The antifriction agent is formed by mixing 15 parts by weight of Swire oil, 20 parts by weight of ethylene glycol, 40 parts by weight of isomeric tridecyl alcohol polyoxyethylene ether and 25 parts by weight of water;

[0064] The preparation method of coiled tubing drilling plug fluid B is: take 3 parts by weight of drag reducer suspension and 2 parts by weight of clay stabilizer and dissolve them in 95 parts by weight of water, st...

Embodiment 3

[0068] A coiled tubing drilling fluid, consisting of coiled tubing drilling fluid A and coiled tubing drilling fluid B;

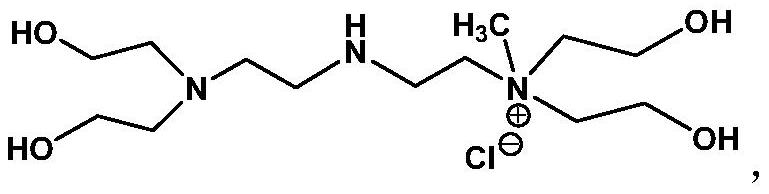

[0069] The preparation method of coiled tubing drilling plug fluid A is as follows: 0.5 parts by weight of clay stabilizer and 0.5 parts of friction reducer are dissolved in 99 parts by weight of water, and stirred or circulated evenly to obtain 100 parts by weight of coiled tubing drilling plug Liquid A; Wherein, the clay stabilizer adopts the sulfonyl quaternary ammonium salt VII with the following chemical structural formula:

[0070] The antifriction agent is formed by mixing 10 parts by weight of Swire oil, 15 parts by weight of ethylene glycol, 20 parts by weight of isomeric tridecyl alcohol polyoxyethylene ether and 55 parts by weight of water;

[0071] The preparation method of coiled tubing drilling plug fluid B is as follows: take 5 parts by weight of drag reducer suspension and 1 part by weight of clay stabilizer and dissolve them in 94 parts b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com