Gear shaft steel manufacturing method capable of achieving direct cold forging

A manufacturing method and cold forging technology, applied in the field of gear shaft steel and its manufacturing, can solve the problems of increasing energy consumption, increasing production cost, increasing processing cycle, etc., to achieve improved steel shaping, cold working shaping, and good surface quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

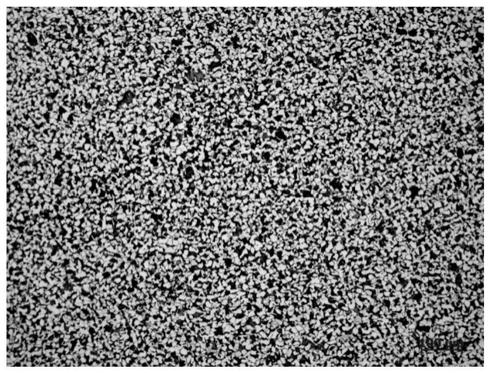

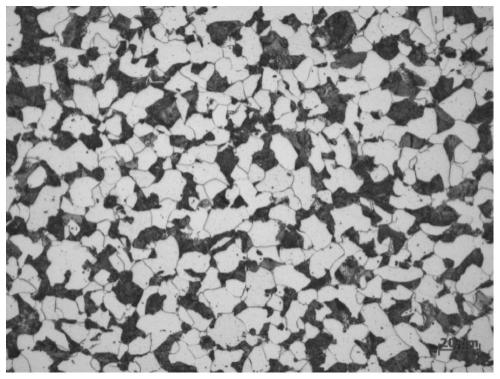

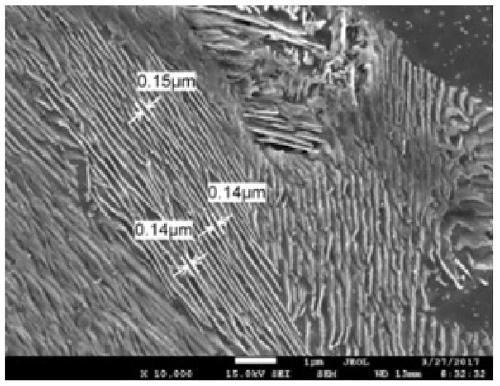

Image

Examples

Embodiment 1—3

[0032] Manufacture the gear shaft steel that can be directly cold forged in the embodiments of the present invention 1 to 3 according to the following procedures:

[0033] 1) Smelting: After smelting in a 100-ton steelmaking furnace, carry out LF refining outside the furnace. The white slag time is 25-60 minutes, and the total refining time must reach at least 40 minutes. During the degassing process, argon gas is used to stir the molten steel, and the mass percentage of each chemical element is strictly controlled according to the requirements.

[0034] 2) Continuous casting: The molten steel is continuously cast into a 240mm×240mm square billet, and the degree of superheat during pouring in the tundish is controlled to be 10-40°C. In order to control the segregation of materials, advanced end electromagnetic stirring and continuous casting light reduction advanced equipment and technology are used in continuous casting. Gained continuous casting slab chemical composition pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com