Device and method for quickly determining recrystallization temperature of metal material

A technology of recrystallization temperature and metal materials, which is applied in the direction of material crystallization, measuring devices, and analysis of materials, can solve the problems of unintuitive results, inconvenient operation, and high operating costs, so as to quickly determine the recrystallization temperature, reduce errors and man-made Interference, the effect of easy operation of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

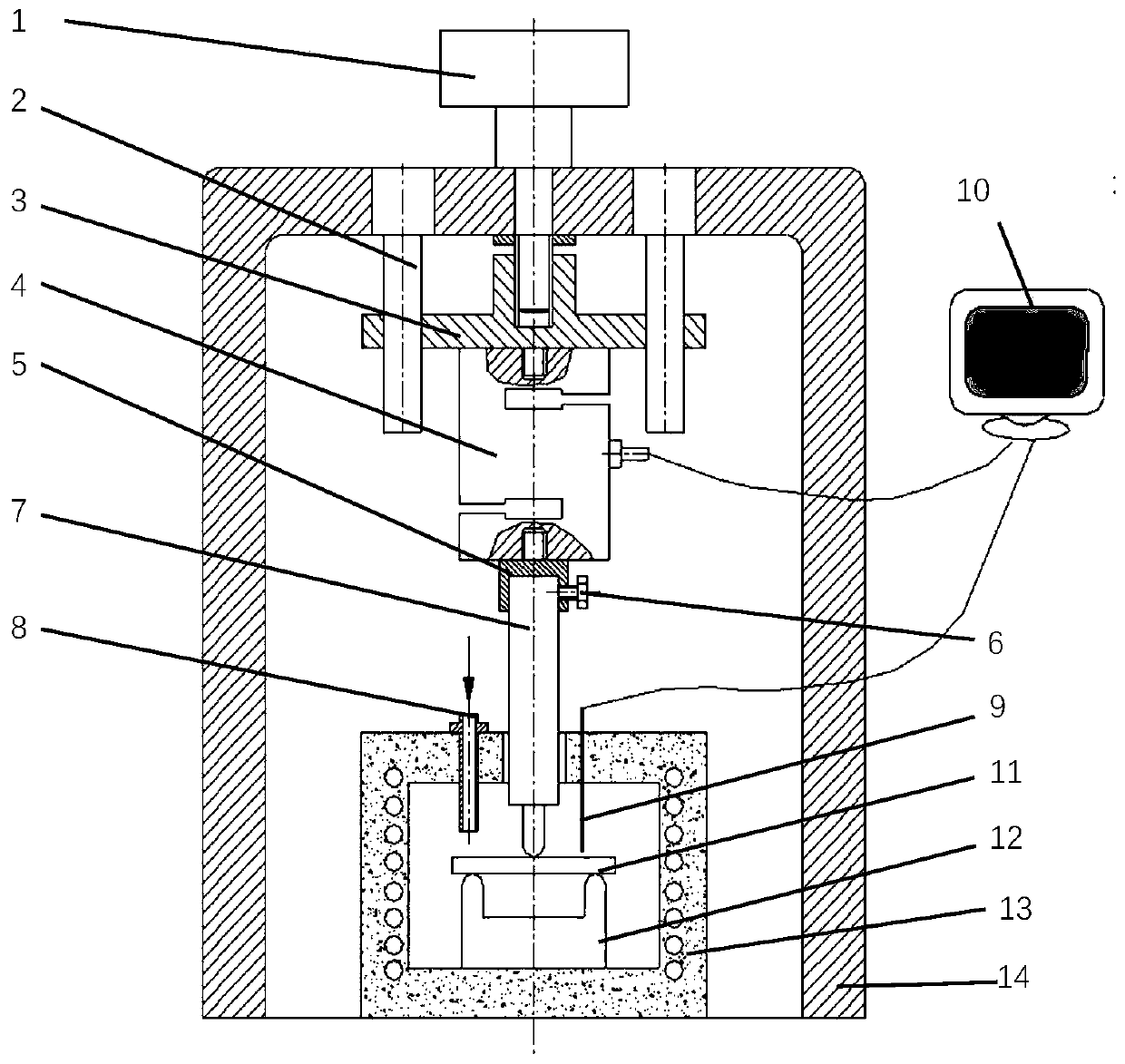

Method used

Image

Examples

Embodiment 1

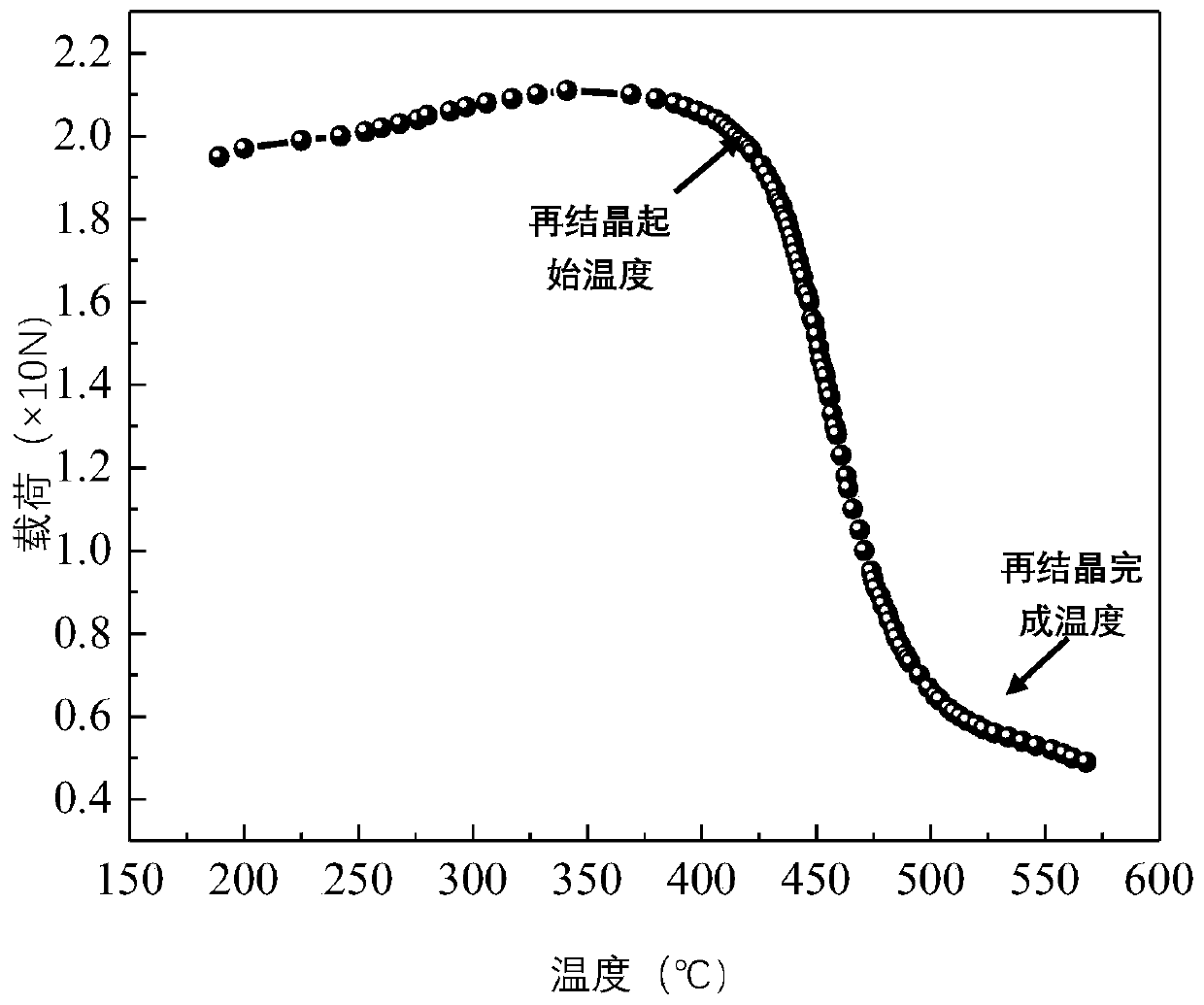

[0024] Example 1: Determination of the recrystallization temperature of 70% cold-rolled deformed H85 brass

[0025] (1) Take a H85 brass sample (length 60mm, width 10mm, thickness 0.5mm) with a cold rolling deformation of 70%, perform three-point bending deformation under the protection of argon, and keep the load constant at 20N;

[0026] (2) Continuously heat the heat treatment furnace at a heating rate of 0.5°C / s, and record the continuous temperature rise load-temperature change curve, such as figure 2 shown;

[0027] (3) Accurately analyze the alloy recrystallization temperature according to the metal material heating load-temperature change curve.

Embodiment 2

[0028] Example 2: Determination of the recrystallization temperature of 90% cold-rolled deformed Cu-Cr-Zr alloy

[0029](1) Take a C18150 sample (length 70mm, width 15mm, thickness 1.0mm) with a cold rolling deformation of 90%, perform three-point bending deformation under the protection of argon, and keep the load constant at 25N;

[0030] (2) Continuously heat the heat treatment furnace at a heating rate of 0.5°C / s, and record the continuous heating load-temperature change curve;

[0031] (3) Accurately analyze the alloy recrystallization temperature according to the metal material heating load-temperature change curve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com