Efficient three-dimensional sulfide end face coupler applied to communication waveband and preparation method thereof

An end-face coupling and sulfide technology, which is used in the coupling of optical waveguides, instruments, optical waveguides and light guides, etc., can solve the problems of large mode field mismatch loss, high insertion loss of on-chip devices, and low theoretical coupling efficiency, so as to avoid indirect Insertion loss, low insertion loss, solve the effect of low coupling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

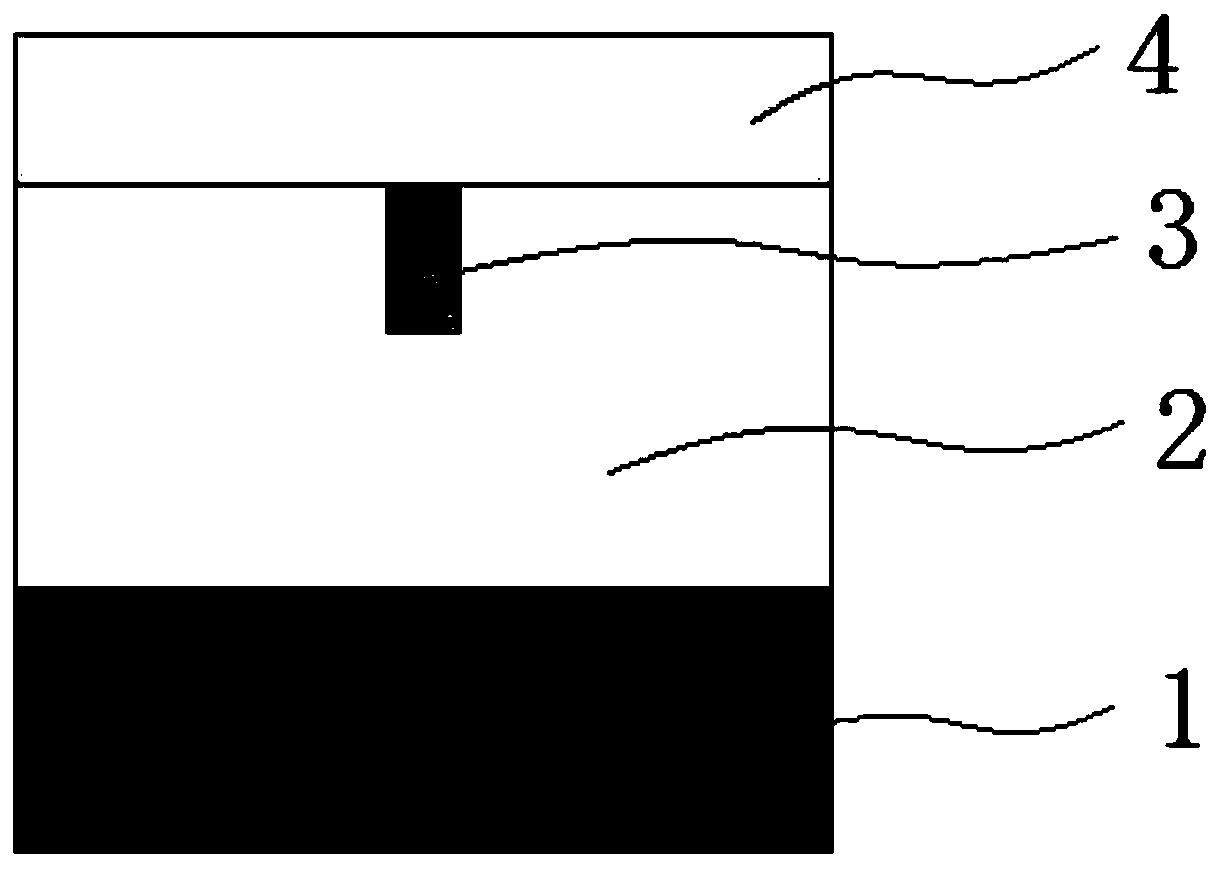

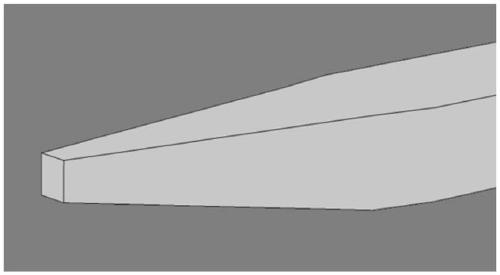

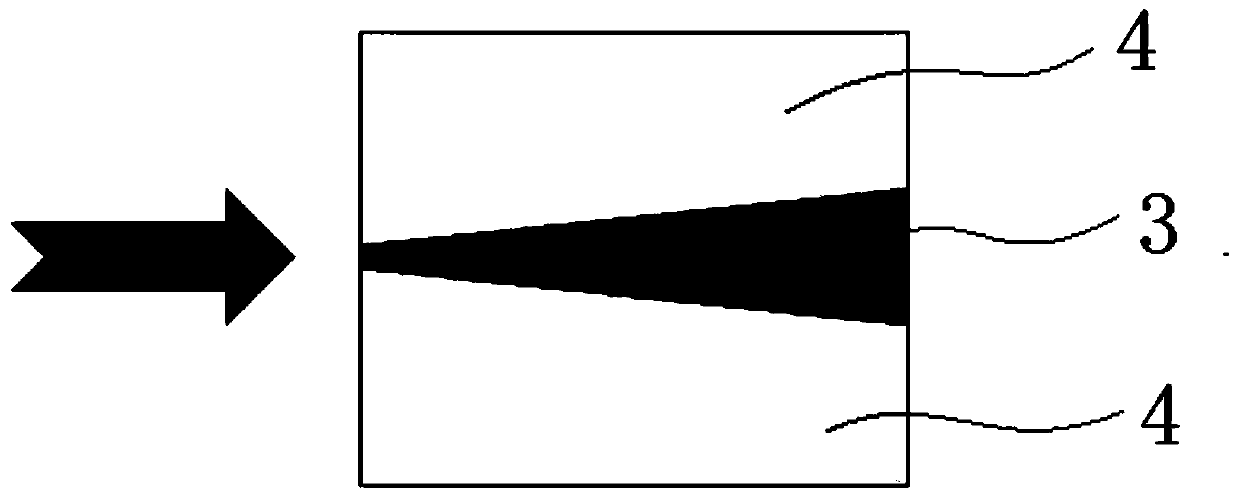

[0031] combine Figure 5 and Figure 6 To illustrate this embodiment, germanium, arsenic and sulfur compounds are selected as the material for the core 3 of the end-face coupler, and the refractive index of the germanium, arsenic and sulfur compounds in the 1550 nm band can be made to be 2.3029 through compound composition design. The design of the size of the narrow end of the fiber core 3 can effectively amplify the waveguide mode field to match the input light field. The size of the wide end of the coupler core 3 is suitable for dispersion control of nonlinear devices in the 1550nm communication band. The upper cladding layer 4 and the lower cladding layer 2 are silicon dioxide, and the refractive index at a wavelength of 1550 nm is 1.444. The height of the upper cladding layer 4 can at least be embedded in the core 3 layers, and the height of the lower cladding layer 2 is 3 μm.

[0032] The width of the narrow end of the core 3 of the sulfide end-face coupler is 150nm-4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com