Method for preparing perforated structure optical cavity F-P optical fiber sensor based on gold-gold bonding

A technology of optical fiber sensor and optical cavity, which is applied in the direction of using optical devices to transmit sensing components, metal material coating technology, vacuum evaporation plating, etc., can solve the problem of low production efficiency of F-P optical fiber sensors, the inability to promote large-scale utilization, and bonding Process requirements are very high, to achieve the effect of ensuring alignment, high controllability, and no chipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

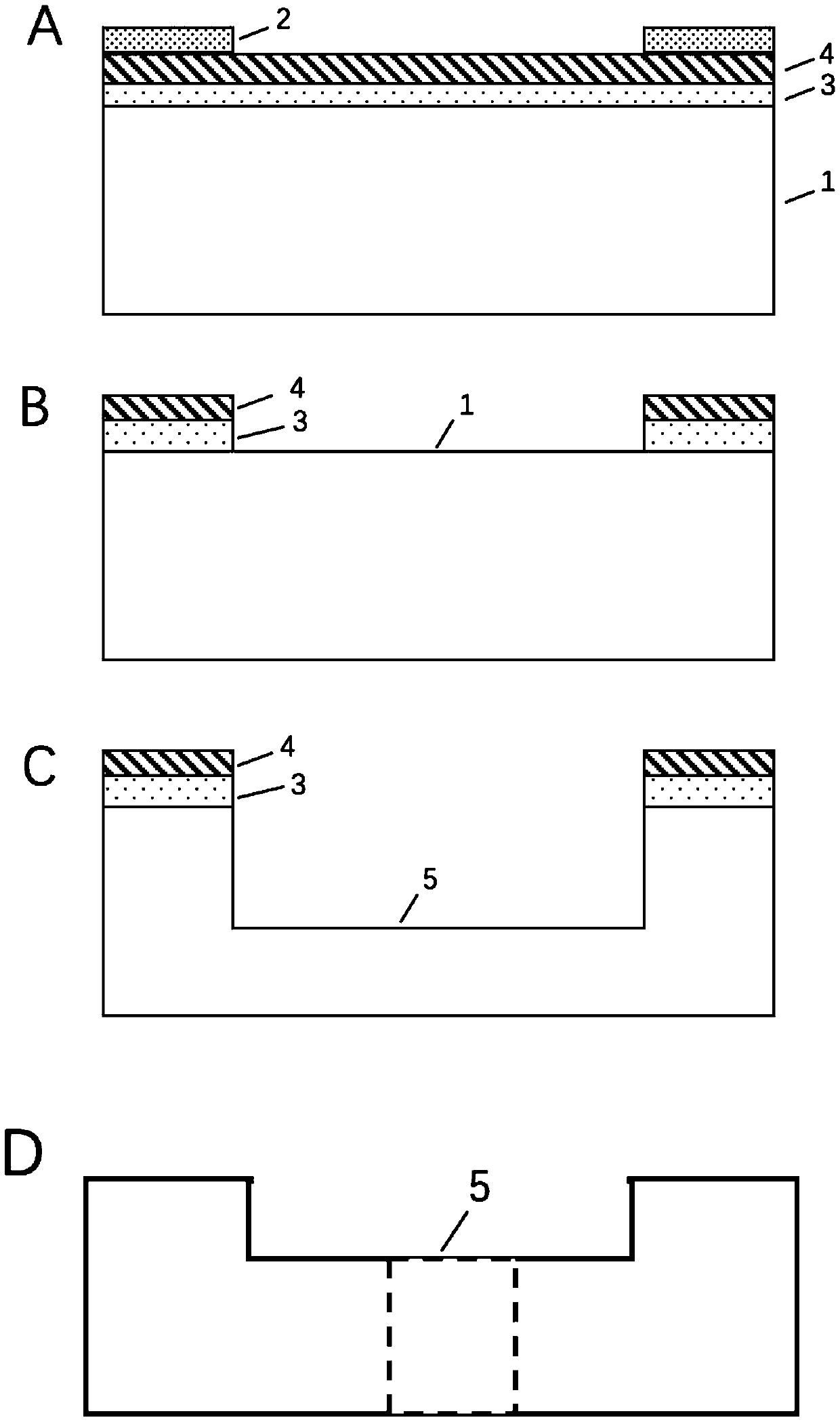

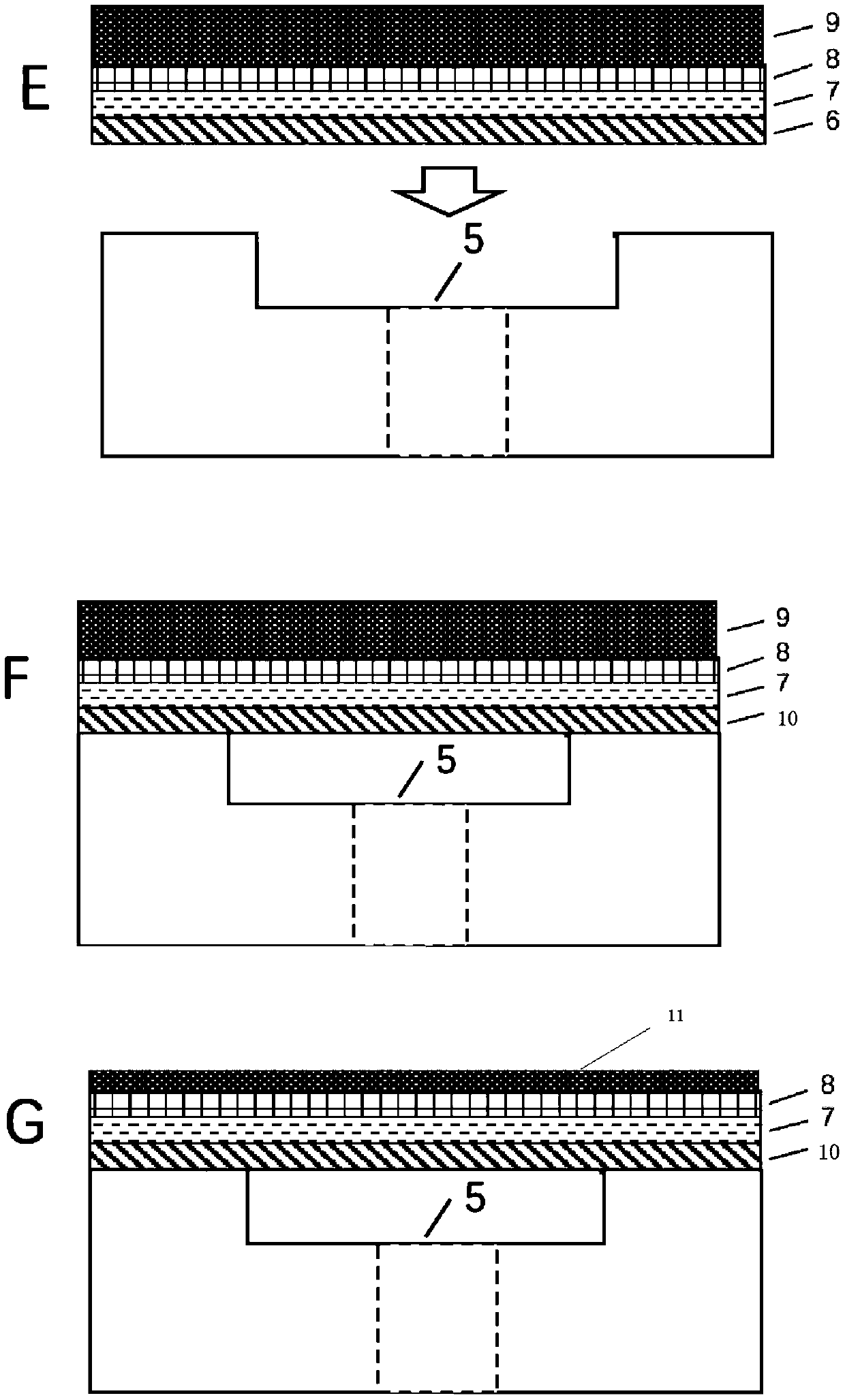

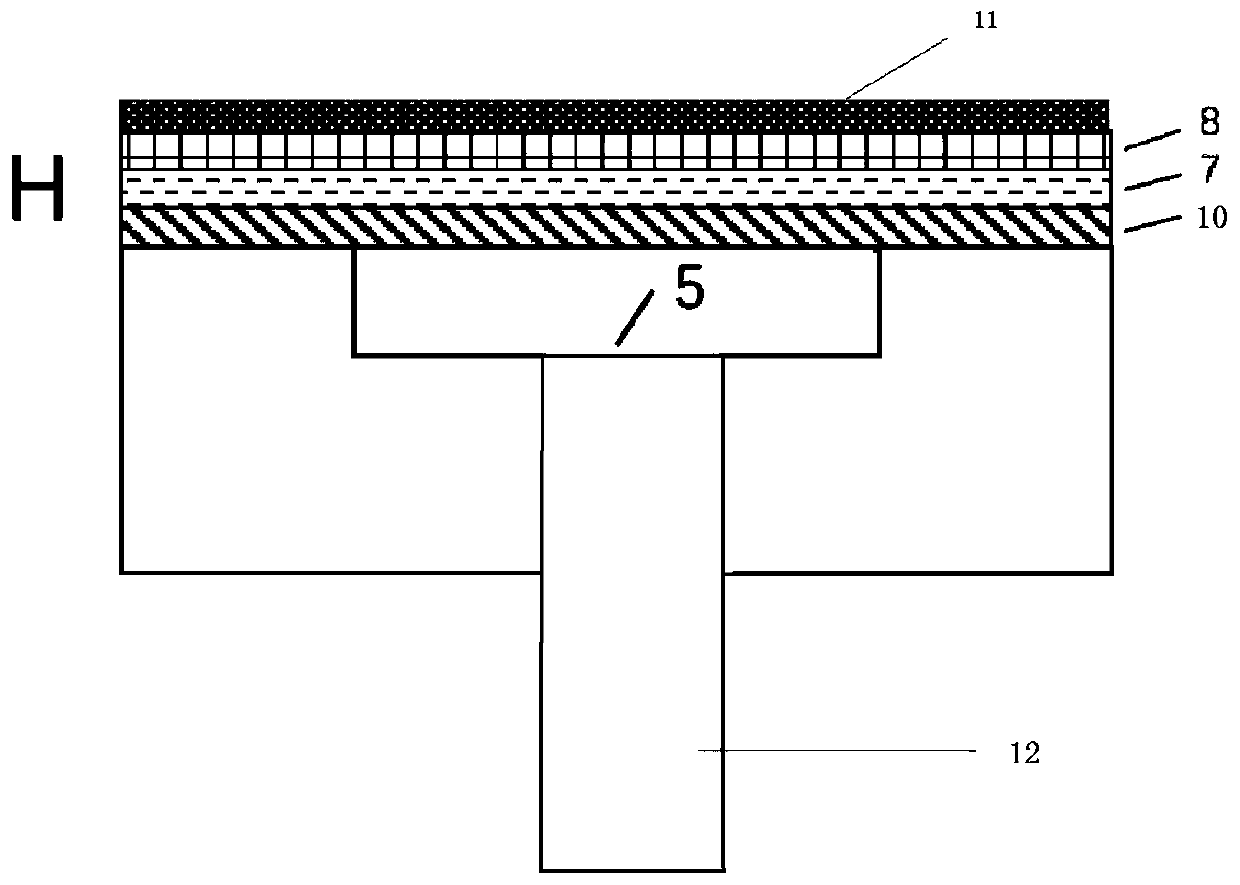

[0047] A method for preparing a perforated structure optical cavity F-P fiber sensor based on gold-gold bonding,

[0048] Ni / Au and Ti / Pt / Au thin films were prepared by sputtering on borosilicate glass and silicon wafer respectively, and a patterned Ni / Au mask was formed on borosilicate glass by wet etching. The optical cavity is etched on the borosilicate glass, and the laser drilling technology is used to process the penetrating hole on the borosilicate glass substrate and then bonded with gold and gold to complete the fabrication of the optical cavity. The specific steps are as follows: figure 1 Shown:

[0049] (1) successively sputtering thickness is the Ni film 3 of 200nm and the Au film 4 of 600nm on the surface of borosilicate glass 1, forms Ni / Au alloy film; One side of borosilicate glass 1 sputtering metal film is thrown with a homogenizer Layer photoresist positive resist (AZ1500) 2, then align the photoresist plate for exposure and development, and put it into the ...

Embodiment 2

[0058] A method for preparing a perforated structure optical cavity F-P optical fiber sensor based on gold-gold bonding as described in Example 1, the difference is:

[0059] The laser drilling is femtosecond laser drilling, the femtosecond laser wavelength is 800nm, the pulse width is 120fs, the repetition frequency is 250KHz, and the maximum pulse energy is 6μJ; the diameter of the penetrating hole is 126-130 microns.

experiment example

[0062] Experimental example, spectrum experiment

[0063] Build a test light path, such as image 3 As shown, it includes a data processing terminal 10 , a spectrometer 11 , an output light source 12 , a light circulator 13 , and a sensor 14 . The output light source 12 is connected to the fiber optic circulator 13 , the fiber optic circulator 13 is connected to the sensor 14 , the spectrometer 11 is connected to the fiber optic circulator 13 , and the data processing terminal 10 is connected to the spectrometer 11 . The sensors 14 are optical fiber sensors manufactured in Example 1 and Comparative Example 1, respectively.

[0064] In the experiment, the output light source 12 adopts 850nm wavelength LED, the spectrometer 11 adopts Ocean Optics HR4000 fiber optic spectrometer, and the data processing terminal 10 is a computer processor. The return interference spectrum collected by the spectrometer is as follows: Figure 4 , Figure 5 as shown, Figure 4 In order to compa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com