A multimode fiber coupling system

A technology of multi-mode optical fiber and coupling system, applied in the field of lighting, can solve the problems of large optical fiber coupling loss, enlarged optical fiber diameter, easy burning and melting of optical fiber, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

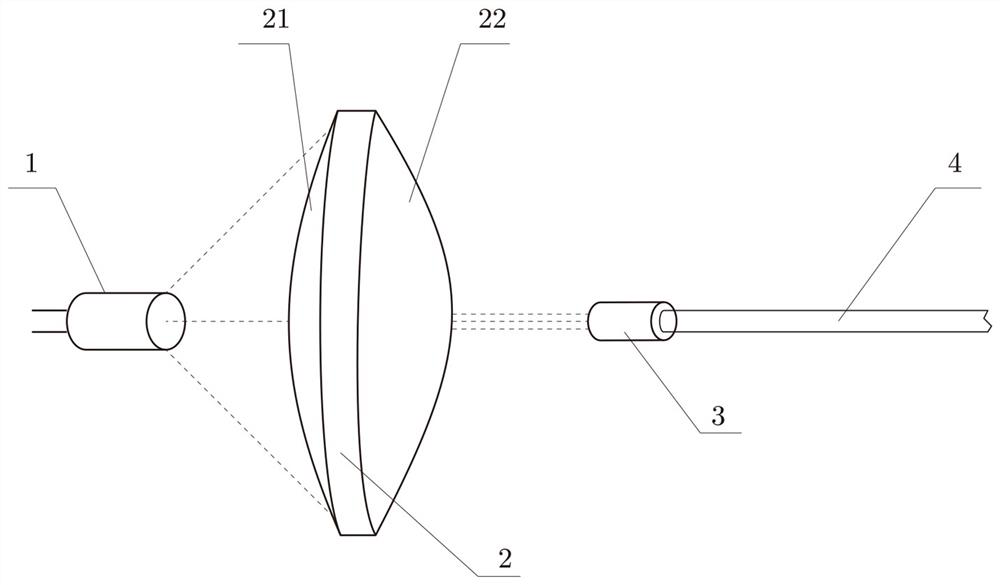

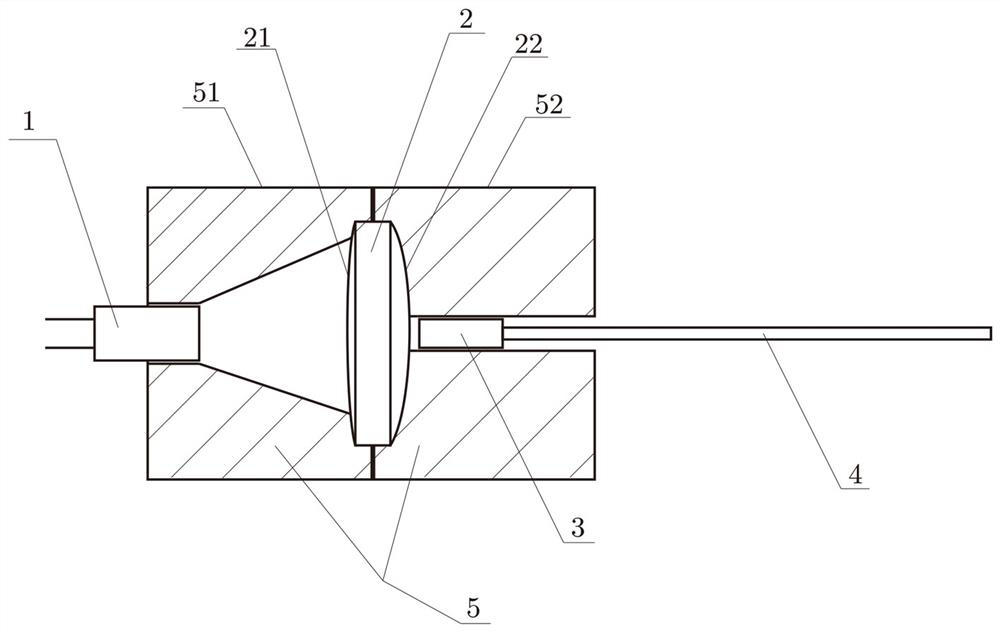

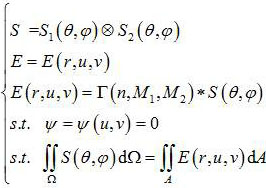

[0043] Example 1: The laser light source is a semiconductor laser, the laser light source 1 emits a special-shaped light beam, the beam is diffused in the horizontal axis direction, and the beam is converged in the vertical axis direction. The multimode optical fiber 4 is a multimode optical fiber with a core diameter of 62.5 μm. The multimode fiber collimator 3 adopts a C-lens fiber collimator. The design method combining ODE and SMS in the non-imaging design method is used to obtain two single-dimensional optical surface characteristic curves at the light entrance end according to the light exiting edge rays in the horizontal and vertical axis directions of the light source, and then combine them into the incoming light by tensor product. End free-form surface 21 . Using the same method, two single-dimensional optical surface characteristic curves of the light-emitting end are obtained according to the light-emitting edge rays in the horizontal and vertical axis directions ...

example 2

[0044] Example 2: The laser light source is a semiconductor laser, the laser light source 1 emits a special-shaped light beam, the beam in the horizontal axis direction is diffused, and the beam in the vertical axis direction is converged. The multimode optical fiber 4 is a multimode optical fiber with a core diameter of 62.5 μm. Optical fiber collimator 3 adopts G-lens optical fiber collimator.

[0045] The design method combining ODE and SMS in the non-imaging design method is used to obtain two single-dimensional optical surface characteristic curves at the light entrance end according to the light exiting edge rays in the horizontal and vertical axis directions of the light source, and then combine them into the incoming light by tensor product. End free-form surface 21 . Using the same method, two single-dimensional optical surface characteristic curves of the light-emitting end are obtained according to the light-emitting edge rays in the horizontal and vertical axis di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com