High-speed avalanche photodetector chip with carrier and manufacturing method thereof

A detector chip, avalanche photoelectric technology, applied in the field of optical transmission network, can solve the problems of low chip coupling efficiency, difficult to achieve receiving sensitivity, reduced capacitance and chip distribution parameters, etc., to improve the chip transmission rate, reduce the overall distribution parameters, The effect of improving the reception sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

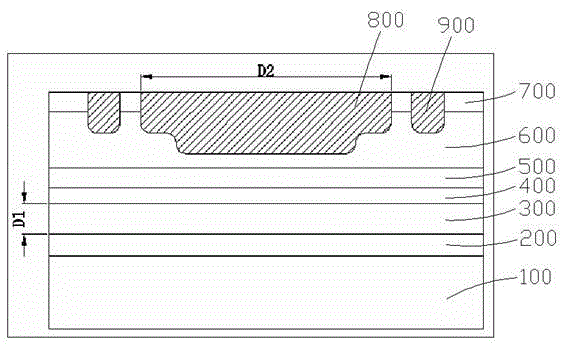

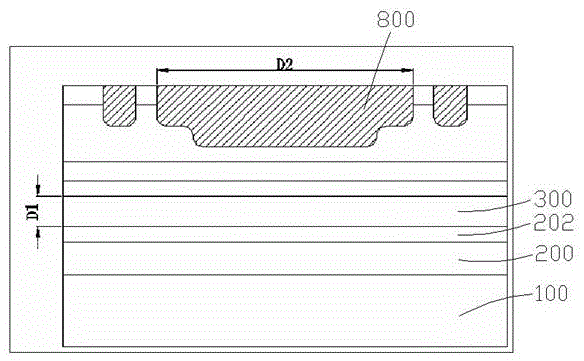

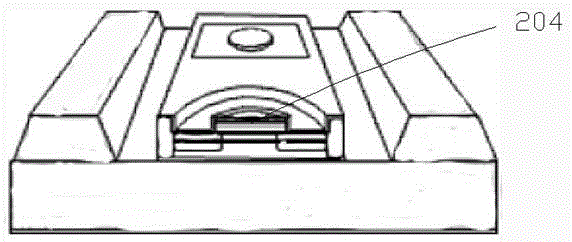

[0032] see Figure 4 to Figure 7 , the present invention provides a high-speed avalanche photodetector chip with a carrier, which is mainly composed of three parts, specifically including: a carrier 13, several solder balls 12 welded on the carrier 13, and soldered to the carrier in a flip-chip manner. The epitaxial wafer 40 on several welding balls 12, the carrier 13 is a ceramic carrier, and a metal pattern is formed on its surface, and the radius R1 of the welding ball 12 is greater than 10um and less than 50um, which can ensure that after welding, the epitaxial wafer 40 and The distance D3 between the carriers 13 is larger than 10um. The epitaxial wafer 40 includes: a substrate 18, a buffer layer 19 formed on the substrate 18, an absorption layer 20 formed on the buffer layer 19, a transition layer 21 formed on the absorption layer 20, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com