Lithium negative pole piece, preparation method thereof and lithium battery

A lithium negative electrode and pole piece technology, applied in the lithium negative pole piece and its preparation, lithium battery field, can solve the problems of lithium waste, shedding, protective layer failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

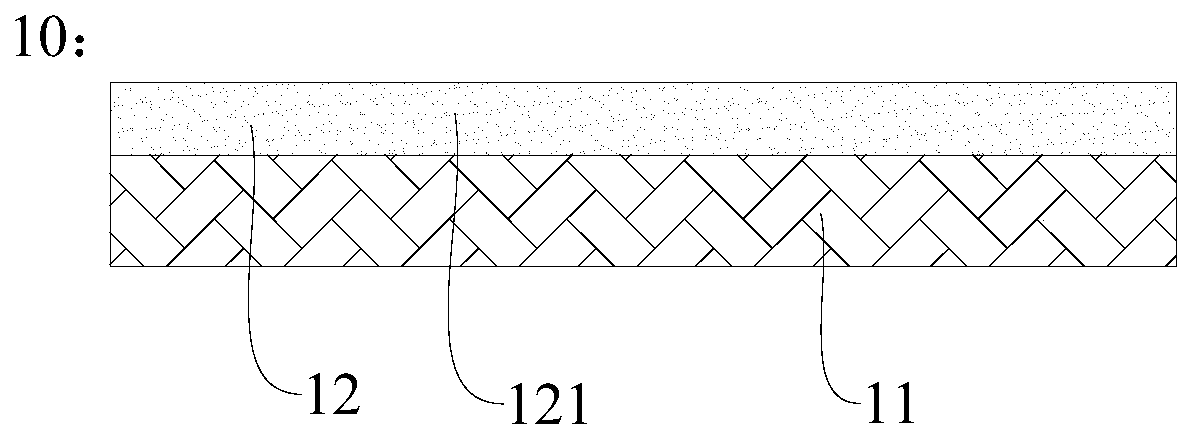

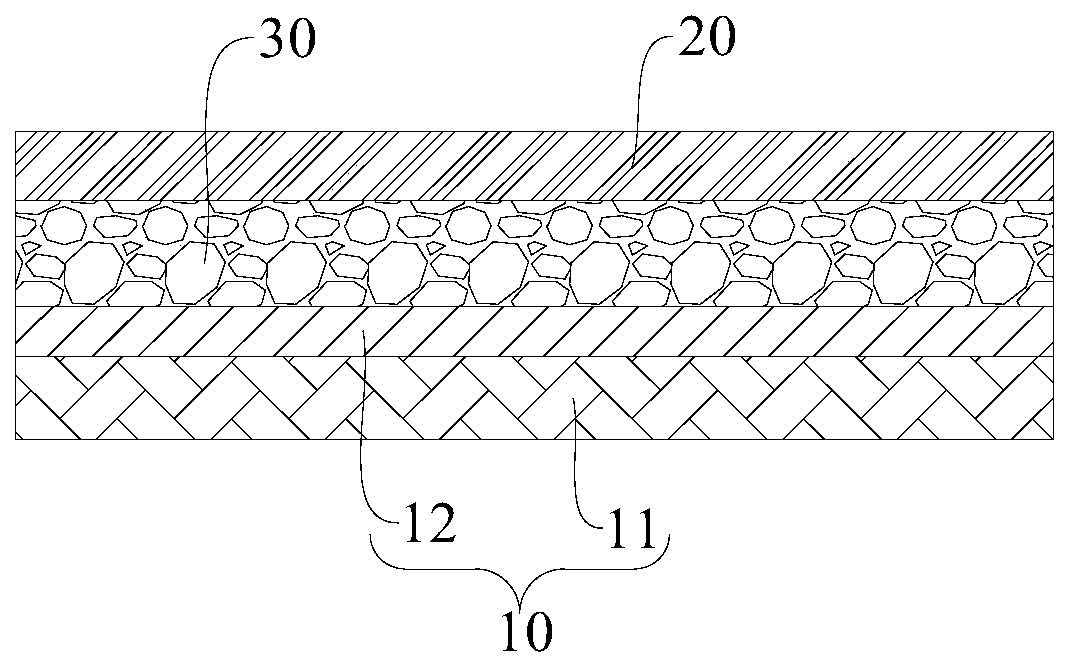

Embodiment 1

[0045] In the glove box, take 0.1g of natural graphite and evenly sprinkle it on the negative electrode of the metal lithium foil, then apply and press it manually, and react at 60°C for 6 hours. Remove the excess graphite powder on the surface to obtain a metal lithium negative electrode sheet with a protective layer of 10nm thickness, wherein the protective layer includes a lithium carbide layer and a graphite layer adsorbed on the surface of the lithium carbide layer, and the lithium negative electrode sheet is cut for later use. The positive electrode material, sulfide electrolyte (LPSCl) is used as the electrolyte membrane, and the assembly cycle test of the all-solid-state battery is carried out. After 27 cycles, the battery capacity retention rate is 96.3%. The specific test results are as follows Figure 4 shown.

Embodiment 2

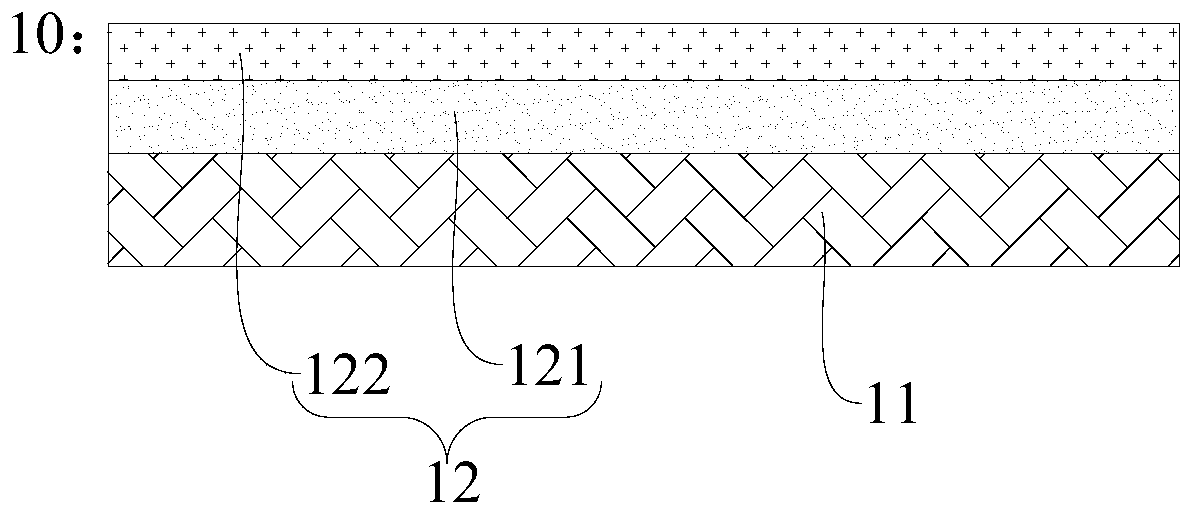

[0047] In the glove box, take 0.05g of scaly graphite and evenly sprinkle it on the metal lithium foil negative electrode, then apply and press it manually, and react at 60°C for 6 hours. Blow off the excess graphite powder on the surface to obtain a metal lithium negative electrode sheet with a protective layer of 10nm thickness, wherein the protective layer includes a lithium carbide layer and a graphite layer adsorbed on the surface of the lithium carbide layer, and the lithium negative electrode sheet is cut for later use. As the positive electrode material, the sulfide electrolyte (LPSCl) is used as the electrolyte membrane, and the assembly cycle test of the all-solid-state battery is carried out. After 27 cycles, the battery capacity retention rate is 82.6%. The specific test results are as follows Figure 5 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com