Nanosilver disinfection antibacterial air filter element and preparation method thereof

An air filter, nano-silver technology, applied in botany equipment and methods, disinfectants, separation methods, etc., can solve problems that affect the use of air filters, air filter mildew, fragile equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

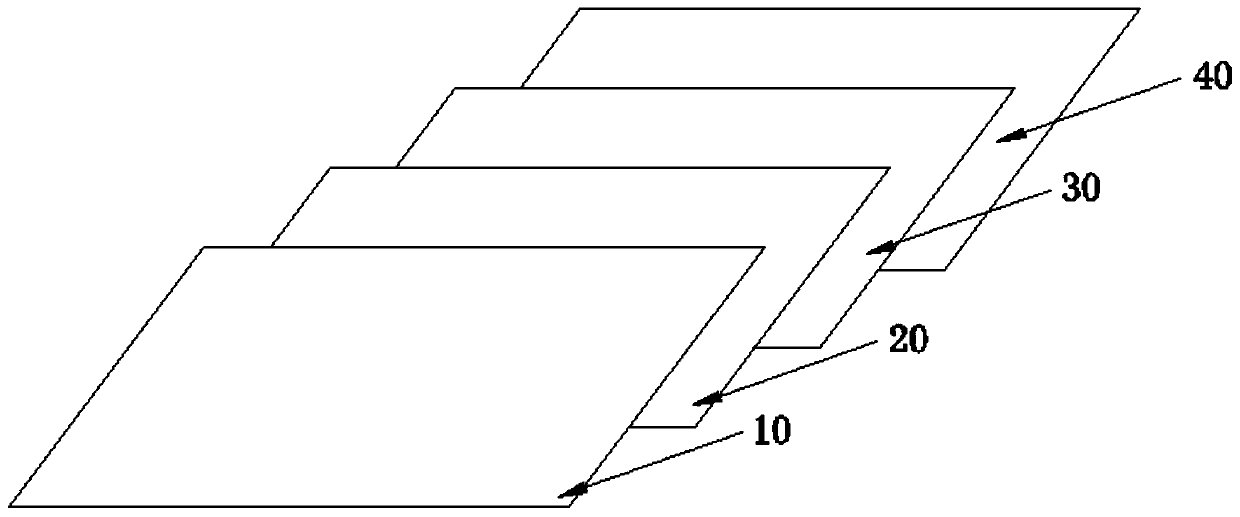

[0035] In the present embodiment, the preparation method of the above-mentioned nano-silver disinfection and antibacterial air filter comprises the following steps:

[0036] S1: Preparation of nano-silver disinfection and antibacterial non-woven fabric 10 in the hydrophobic layer, see Table 1 and Table 2 for details, as follows:

[0037] S11: The preparation of disinfecting and antibacterial nano-silver-silver ion solution, according to parts by weight, including:

[0038]

[0039] S12: Take a suitable hydrophobic non-woven fabric as a carrier, soak the hydrophobic non-woven fabric carrier in the above-mentioned disinfected and antibacterial nano-silver-silver ion solution for 10-30min according to the mass ratio of 1:50-1000;

[0040] S13: Take out the hydrophobic non-woven fabric carrier in the sterilized antibacterial nano-silver-silver ion solution, and dry it at 80-120°C for 10-30min;

[0041] S14: Take out the non-woven fabric after drying, and prepare the nano-silve...

Embodiment 1

[0053] In the present embodiment, the preparation method of the above-mentioned nano-silver disinfection and antibacterial air filter comprises the following steps:

[0054] S1: Preparation of nano-silver disinfection and antibacterial non-woven fabric 10 in the hydrophobic layer, see Table 1 and Table 2 for details, as follows:

[0055] S11: The preparation of disinfecting and antibacterial nano-silver-silver ion solution, according to parts by weight, including:

[0056]

[0057] S12: Take a suitable hydrophobic non-woven fabric as a carrier, and soak the hydrophobic non-woven fabric carrier in the above-mentioned disinfected and antibacterial nano-silver-silver ion solution for 10-30 minutes at a mass ratio of 1:50;

[0058] S13: Take out the hydrophobic non-woven fabric carrier in the sterilized antibacterial nano-silver-silver ion solution, and dry it at 80-120°C for 10-30min;

[0059] S14: Take out the non-woven fabric after drying, and prepare the nano-silver disinf...

Embodiment 2

[0070] In the present embodiment, the preparation method of the above-mentioned nano-silver disinfection and antibacterial air filter comprises the following steps:

[0071] S1: Preparation of nano-silver disinfection and antibacterial non-woven fabric 10 in the hydrophobic layer, see Table 1 and Table 2 for details, as follows:

[0072] S11: The preparation of disinfecting and antibacterial nano-silver-silver ion solution, according to parts by weight, including:

[0073]

[0074] S12: Take a suitable hydrophobic non-woven fabric as a carrier, and soak the hydrophobic non-woven fabric carrier in the above-mentioned disinfected antibacterial nano-silver-silver ion solution for 10-30 minutes according to the mass ratio of 1:200;

[0075] S13: Take out the hydrophobic non-woven fabric carrier in the sterilized antibacterial nano-silver-silver ion solution, and dry it at 80-120°C for 10-30min;

[0076] S14: Take out the non-woven fabric after drying, and prepare the nano-silv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com