SiO2-TiO2 composite metamaterial structure photocatalyst and preparation method thereof

A technology of structured light and catalyst, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of low solar energy utilization, low quantum efficiency, etc., to improve photocatalytic performance and reduce liquid Effect of low surface tension and reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

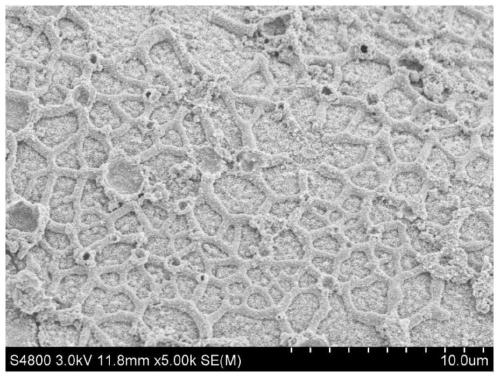

Image

Examples

Embodiment 1

[0015] A SiO 2 -TiO 2 The preparation method of composite metamaterial structure photocatalyst, the steps are as follows:

[0016] (1) Mix styrene and α-methacrylic acid at a ratio of 30:1 by volume, add water to make a 6vol% solution, and heat to 75°C. After the solution is stable, add 0.14g persulfuric acid per 100mL Potassium, reacted for 10 hours to obtain polystyrene sol, then mixed and diluted polystyrene sol with deionized water at a ratio of 1:30, and deposited vertically at 40°C to form colloidal crystals.

[0017] (2) Mix 2mL tetraethyl orthosilicate and absolute ethanol at a ratio of 1:1.5 and stir evenly. After stirring evenly, add 2g of citric acid; take another beaker and mix absolute ethanol and deionized water at a ratio of 1:1. Prepare 10 mL of solution. After the two solutions were mixed and stirred evenly, ammonia water was added to adjust the pH value of the solution to 8, and after stirring for 5 minutes, SiO 2 Sol. Prepared SiO 2 The sol is impregna...

Embodiment 2

[0021] A SiO 2 -TiO 2 The preparation method of composite metamaterial structure photocatalyst, the steps are as follows:

[0022] (1) Mix styrene and α-methacrylic acid evenly at a ratio of 15:1 by volume, add water to make 6vol% and heat to 80°C. After the solution is stable, add 0.10g of potassium persulfate per 100mL to react After 8 hours, the polystyrene sol was obtained, and then the polystyrene sol was mixed and diluted with deionized water at a ratio of 1:20, and then deposited vertically at 40°C to form colloidal crystals.

[0023] (2) Mix 2mL tetraethyl orthosilicate and absolute ethanol at a ratio of 1:1.5 and stir evenly. After stirring evenly, add 3g of citric acid; take another beaker and mix absolute ethanol and deionized water at a ratio of 1:1 Prepare 10 mL of solution. After the two solutions were mixed and stirred evenly, ammonia water was added to adjust the pH value of the solution to 8, and after stirring for 5 minutes, SiO 2 Sol. Prepared SiO 2 Th...

Embodiment 3

[0026] A SiO 2 -TiO 2 The preparation method of composite metamaterial structure photocatalyst, the steps are as follows:

[0027] (1) Mix styrene and α-methacrylic acid evenly at a ratio of 30:1 by volume, add water to make 6vol% and heat to 85°C. After the solution is stable, add 0.2g potassium persulfate per 100mL to react After 9 hours, the polystyrene sol was obtained, and then the polystyrene sol was mixed and diluted with deionized water at a ratio of 1:15, and then deposited vertically at 40°C to form colloidal crystals.

[0028] (2) Mix 3mL tetraethyl orthosilicate and absolute ethanol at a ratio of 1:1.5 and stir evenly. After stirring evenly, add 2g of citric acid; take another beaker and mix absolute ethanol and deionized water at a ratio of 1:1 Prepare 12mL of solution. After the two solutions were mixed and stirred evenly, ammonia water was added to adjust the pH value of the solution to 8, and after stirring for 5 minutes, SiO 2 Sol. Prepared SiO 2 The sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com