Double-flow monodisperse droplet flow generation method and device

A generating device and monodisperse technology, applied in chemical instruments and methods, fluid controllers, measuring tubes/pipettes, etc., to achieve the effects of precise control of the frequency range, simple operation, and improved utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

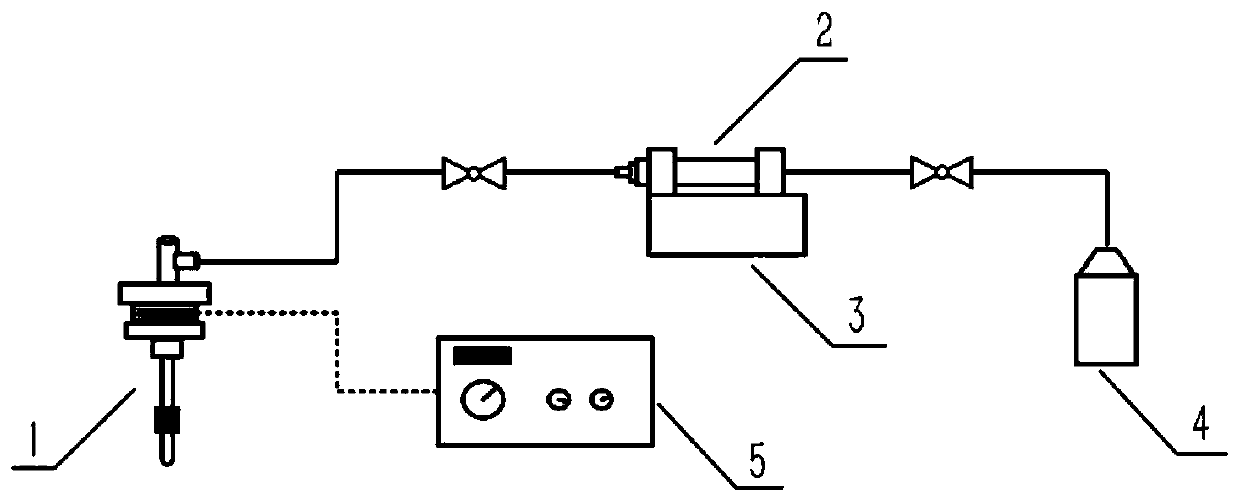

[0044] like figure 1As shown, the dual-flow monodisperse droplet flow generating device provided in this embodiment includes: a droplet flow generator 1 , a syringe 2 , a syringe pump 3 , a liquid storage bottle 4 , and a piezoelectric driver 5 .

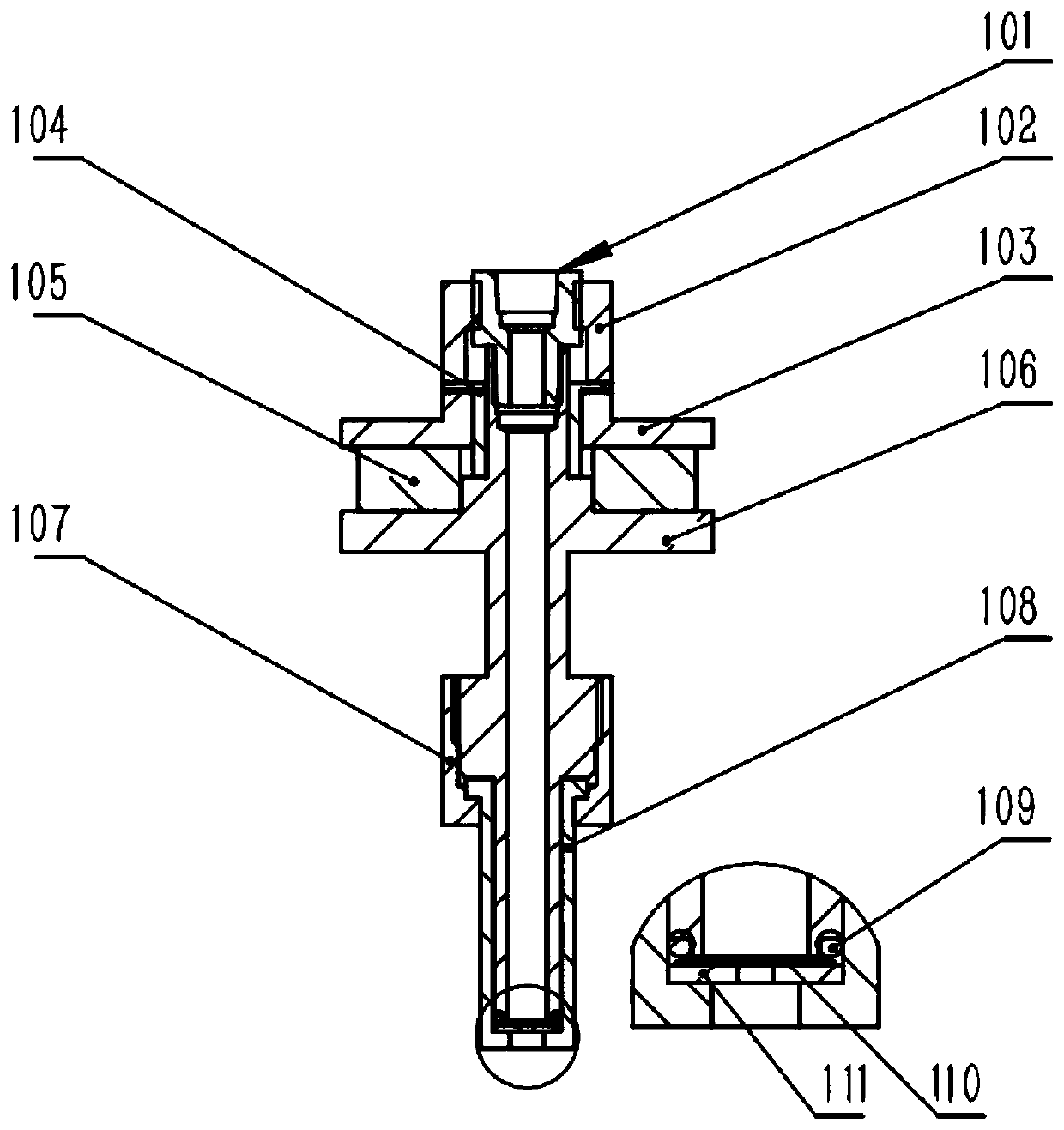

[0045] like figure 2 As shown, the droplet flow generator 1 includes: an external thread adapter 101, an internal thread pressure ring 102, an annular end cap 103, a "T"-shaped cylinder 104, a piezoelectric ceramic sheet 105, a support chamber 106, a spray chamber 108 and Spray cavity fixing cap 107; "T" type cylinder 104 is placed inside the annular end cover 103, and the piezoelectric ceramic sheet 105 is fixed on the shoulder of the support cavity 106; one end of the external thread adapter 101 is connected to the support cavity 106 through threads, The other end is connected with the intern...

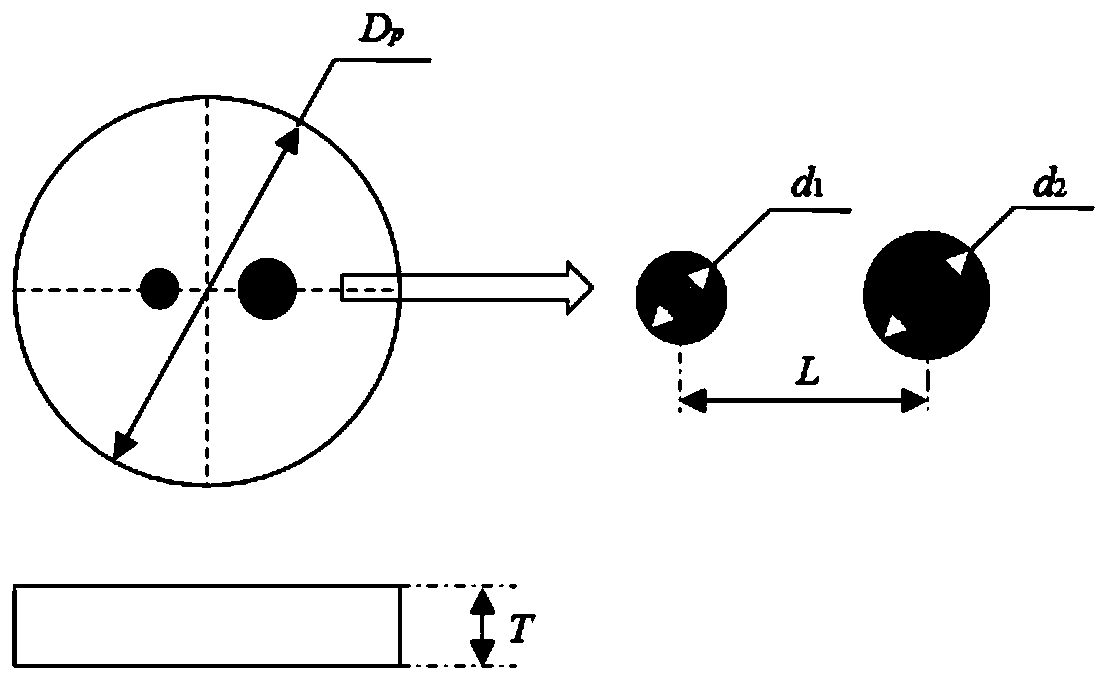

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com