A preparation method for forging forming of a near-β-type titanium alloy forging with high strength and high toughness

A high-strength, high-toughness, titanium alloy technology, applied in metal processing equipment and other directions, can solve the problems of near-β-type titanium alloy forgings that are difficult to match in strength and plasticity, difficult to obtain homogeneous fine ternary structure, and low fracture toughness and fatigue resistance. , to achieve the effects of stable and controllable quality, promotion of tissue uniformity, and high strength and plasticity matching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

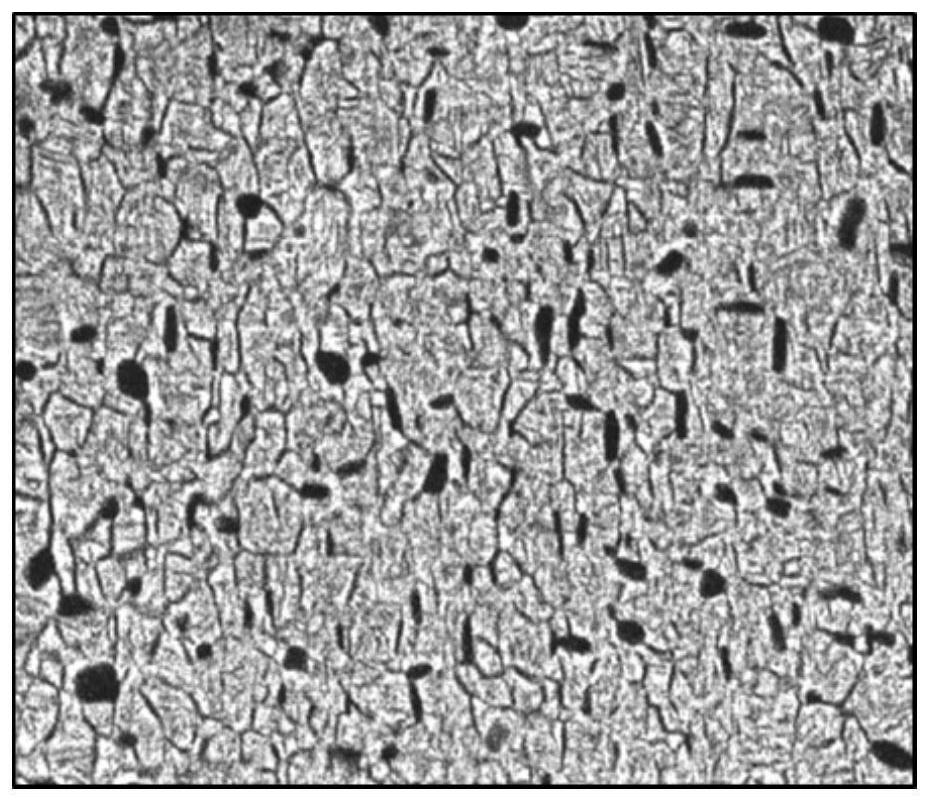

[0033] 1) The Ti-55531 near-β-type titanium alloy ingot of Φ220 specification is used, and the phase transition temperature of the ingot is 845°C. Use a resistance furnace to heat the ingot to 1100°C above the β-phase transition temperature, keep it warm for 8 hours, then use a 3,500-ton fast forging machine to repeatedly upset and elongate in the β-phase region for 3 times, and the final forging temperature is not lower than 850°C. The total forging ratio is controlled at 2.5. After forging, it is cooled to room temperature in the air and subjected to surface grinding treatment to obtain a forged billet with a cross-sectional diameter of 200-220 mm.

[0034] 2) Using a resistance furnace, heat the forging billet obtained in step 1) to 855°C, keep it warm for 2 hours, and carry out radial forging on a 600-ton precision forging machine. 20mm / s, the total forging time is 15 minutes, the total forging ratio is 6, and the final forging temperature is not less than 815°C.

[0035]...

Embodiment 2

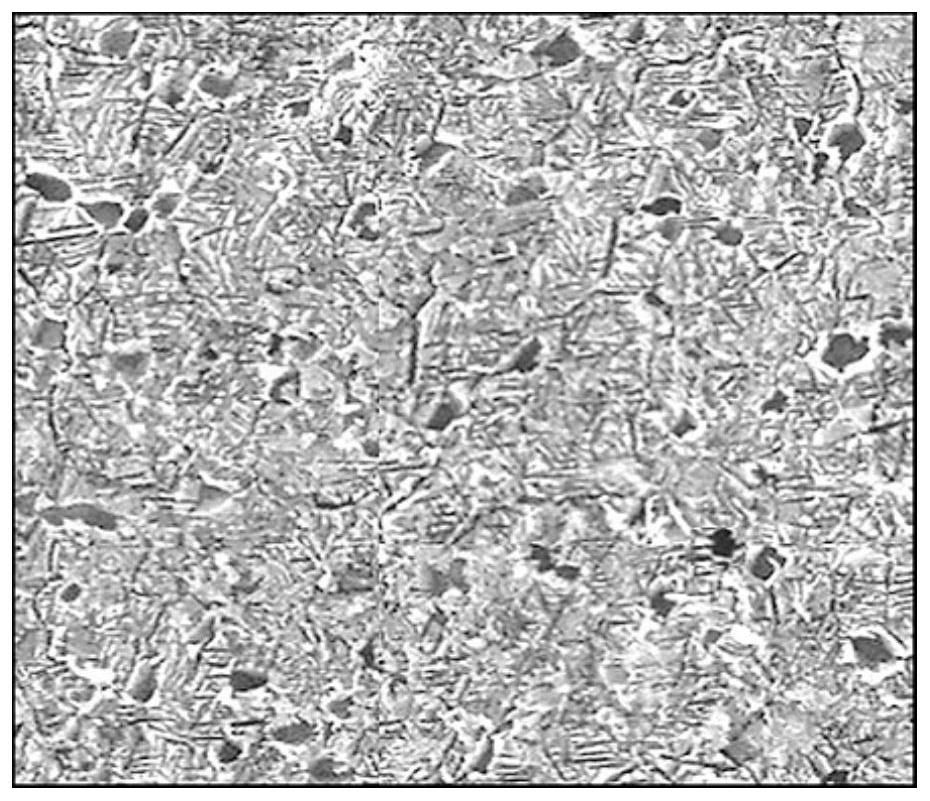

[0043] 1) The Ti-7333 near-β-type titanium alloy ingot of Φ220 specification is used, and the phase transition temperature of the ingot is 855°C. Use a resistance furnace to heat the ingot to 1150°C above the β-phase transition temperature, keep it warm for 8 hours, then use a 3,500-ton fast forging machine to repeatedly upset and elongate in the β-phase area for 3 times, and the final forging temperature is not lower than 860°C. The total forging ratio is controlled at 2.5. After forging, it is cooled to room temperature in the air and subjected to surface grinding treatment to obtain a forged billet with a cross-sectional diameter of 220-250 mm.

[0044] 2) Using a resistance furnace, heat the forging billet obtained in step 1) to 865°C, keep it warm for 2 hours, and carry out radial forging on a 600-ton precision forging machine. 20mm / s, the total forging time is 15 minutes, the total forging ratio is 6, and the final forging temperature is not less than 825°C.

[0045] 3)...

Embodiment 3

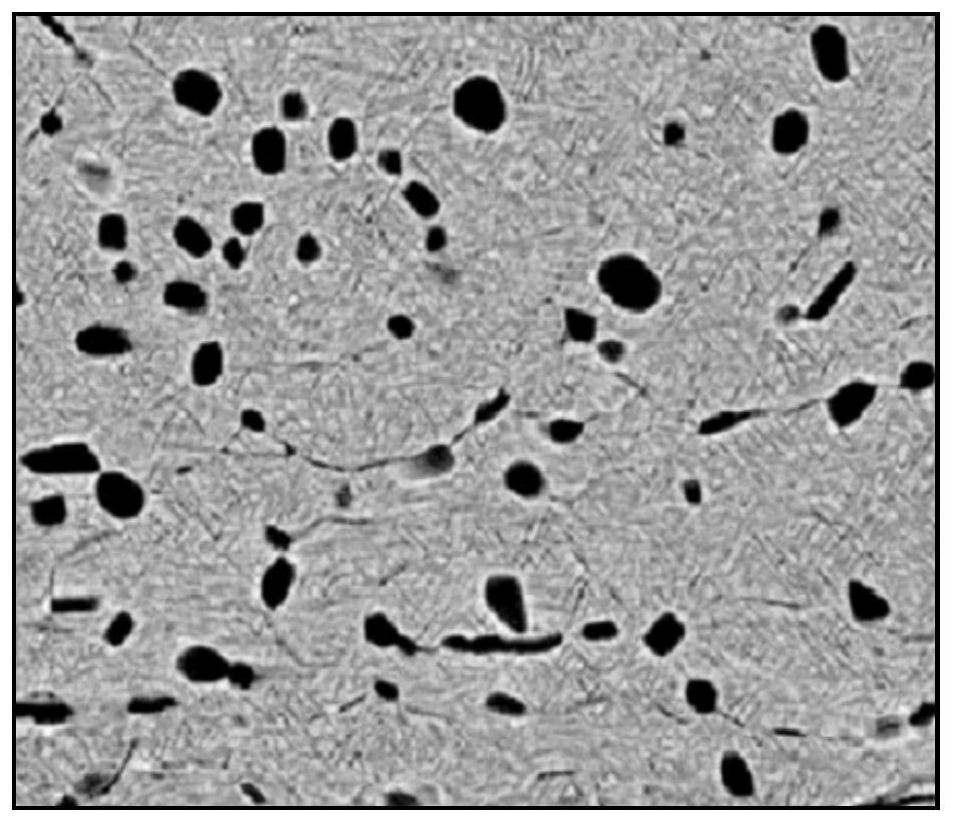

[0053] 1) The Ti-1023 near-β-type titanium alloy ingot of Φ260 specification is used, and the phase transition temperature of the ingot is 805°C. Use a resistance furnace to heat the ingot to 1050°C above the β-phase transition temperature, keep it warm for 10 hours, and then use a 3,500-ton fast forging machine to repeatedly upset and elongate in the β-phase area for 3 times, and the final forging temperature is not lower than 805°C. The total forging ratio is controlled at 4.5. After forging, it is cooled to room temperature in the air and subjected to surface grinding treatment to obtain a forged billet with a cross-sectional diameter of 240-270mm.

[0054] 2) Using a resistance furnace, heat the forging billet obtained in step 1) to 815°C, keep it warm for 2 hours, and carry out radial forging on a 600-ton precision forging machine. 25mm / s, the total forging time is 12 minutes, the total forging ratio is 8, and the final forging temperature is not less than 785°C.

[0055...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com