Preparation method for MOF crystal form transformation

A technology of crystal transformation and ionic liquid, which is applied in the preparation of MOF crystal transformation and metal organic framework preparation, to achieve the effect of accelerating crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

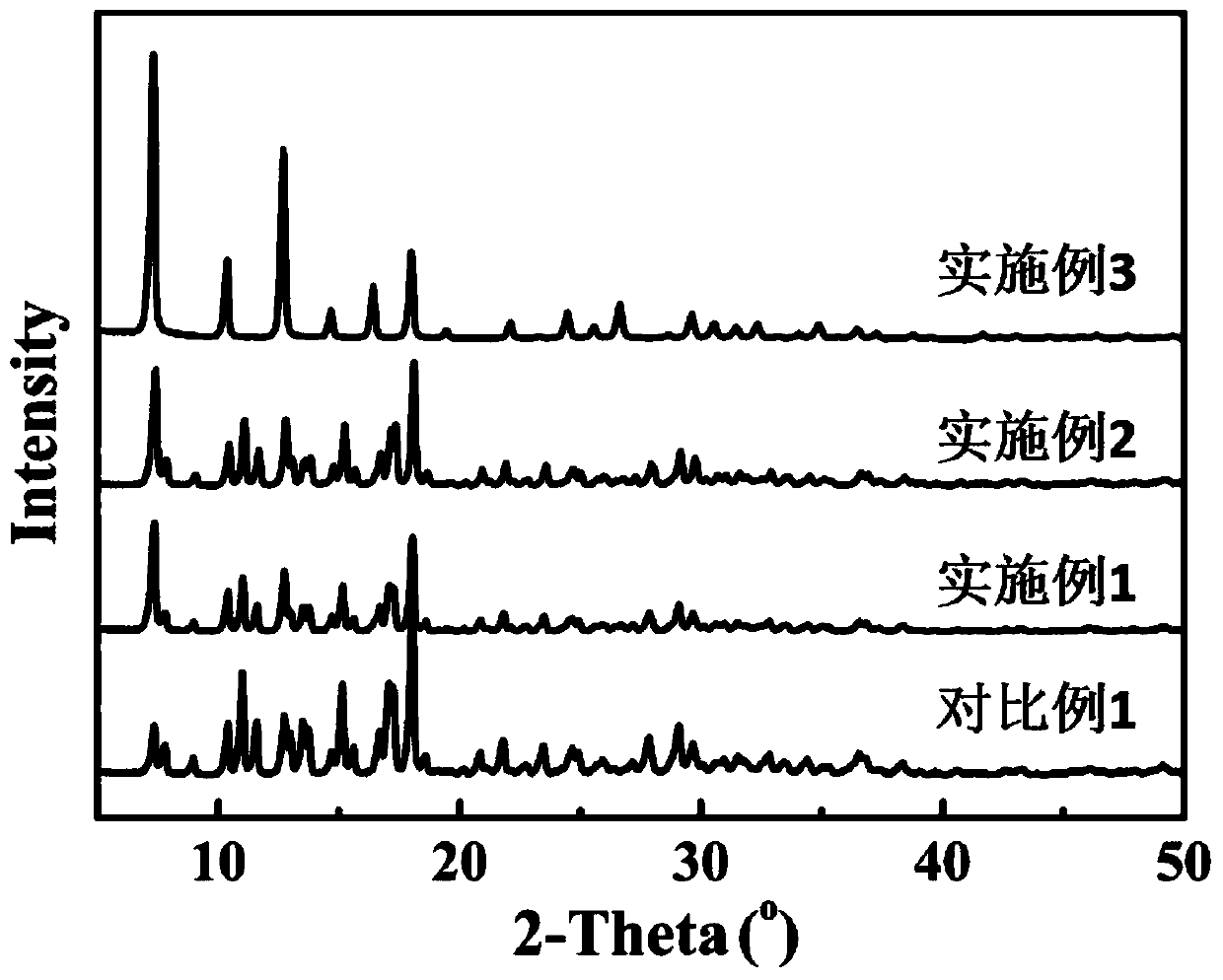

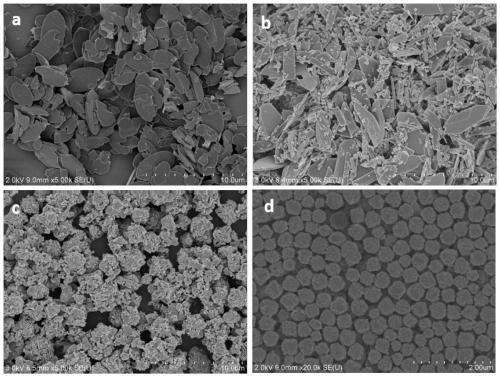

[0027] The composition of solution B was changed, and 1.30 g of HIm was dissolved in a mixed solvent composed of 39.75 g of water and 0.25 g of ionic liquid 1-hexyl-3-methylimidazolium chloride to form solution B, and the rest were the same as in comparative example 1. Its XRD such as figure 1 As shown, the obtained ZIF-L / ZIF-8 mixed crystal form. Scanning electron microscopy shows irregular leaf morphology, such as figure 2 (b) shown.

Embodiment 2

[0029] The composition of solution B was changed, and 1.30 g of HIm was dissolved in a mixed solvent composed of 37.5 g of water and 2.5 g of ionic liquid 1-hexyl-3-methylimidazolium chloride to form solution B, and the rest were the same as in comparative example 1. Its XRD such as figure 1 As shown, the obtained ZIF-L / ZIF-8 mixed crystal form. Immediately after the solution AB was mixed, a large number of precipitates were produced, and the crystallization speed was obviously accelerated. Scanning electron microscopy reveals irregular particles such as figure 2 (c) shown.

Embodiment 3

[0031] The composition of solution B was changed, and 1.30 g of HIm was dissolved in a mixed solvent composed of 35 g of water and 5 g of ionic liquid 1-hexyl-3-methylimidazolium chloride to form solution B, and the rest were the same as in Comparative Example 1. Immediately after the solution AB was mixed, a large amount of precipitates were produced, and its XRD was as follows: figure 1 As shown, a single crystal form of ZIF-8 was obtained. Scanning electron microscopy shows regular-sized particles, about 400nm, such as figure 2 (d) shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com