Modified asphalt waterproof coating material

A technology of modified asphalt and waterproof coatings, applied in asphalt coatings, fire-resistant coatings, coatings, etc., can solve the problems that waterproof coatings cannot achieve waterproof effect, coating film damage, etc., to improve high-temperature rutting resistance and aging resistance. , Good anti-aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

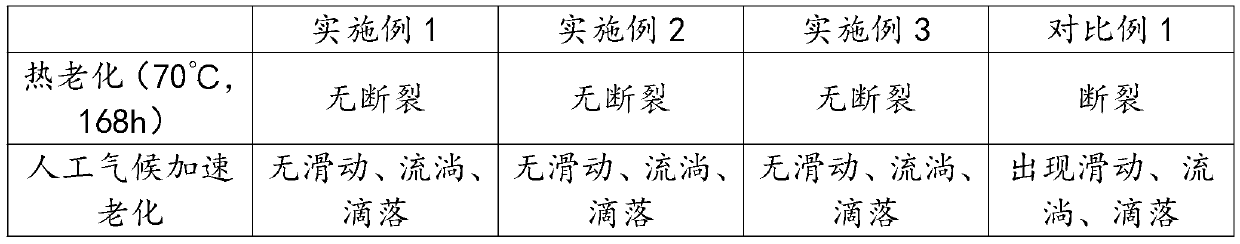

Examples

Embodiment 1

[0029] A modified asphalt waterproof coating, made of the following raw materials in parts by weight: 100 parts of modified asphalt emulsion, 25 parts of styrene-butadiene rubber, 10 parts of desulfurization powder, 20 parts of pine tar, 10 parts of lauric acid, dibutyl phthalate 5 parts of ester, 25 parts of talcum powder, 3 parts of polyethylene glycol;

[0030] The preparation steps of this waterproof coating are as follows:

[0031] Step S1: adding styrene-butadiene rubber and desulfurized powder into a pulverizer for pulverization, passing through a 60-mesh sieve and mixing to obtain the first mixture;

[0032] Step S2: Add the modified asphalt emulsion into the stirring tank, stir at a speed of 1500r / min and a temperature of 140°C, and add the first mixture and pine tar prepared in step S1, and stir for 30min to obtain the first colloid;

[0033] Step S3: Add the first base liquid prepared in step S2 into a stirred tank, stir at a rotating speed of 3000r / min and a temp...

Embodiment 2

[0041] A modified asphalt waterproof coating, made of the following raw materials in parts by weight: 110 parts of modified asphalt emulsion, 28 parts of styrene-butadiene rubber, 11 parts of desulfurization powder, 23 parts of pine tar, 13 parts of lauric acid, dibutyl phthalate 7 parts of ester, 28 parts of talcum powder, 4 parts of polyethylene glycol;

[0042] The preparation steps of this waterproof coating are as follows:

[0043] Step S1: adding styrene-butadiene rubber and desulfurized powder into a pulverizer for pulverization, passing through a 70-mesh sieve and mixing to obtain the first mixture;

[0044] Step S2: Add the modified asphalt emulsion into the stirring tank, stir at a speed of 1800r / min and a temperature of 145°C, add the first mixture and pine tar prepared in step S1, and stir for 40min to obtain the first colloid;

[0045]Step S3: Add the first base liquid prepared in step S2 into a stirring tank, stir at a speed of 3500r / min, and a temperature of 1...

Embodiment 3

[0053] A modified asphalt waterproof coating, made of the following raw materials in parts by weight: 120 parts of modified asphalt emulsion, 30 parts of styrene-butadiene rubber, 13 parts of desulfurization powder, 25 parts of pine tar, 15 parts of lauric acid, dibutyl phthalate 8 parts of ester, 30 parts of talcum powder, 5 parts of polyethylene glycol;

[0054] The preparation steps of this waterproof coating are as follows:

[0055] Step S1: adding styrene-butadiene rubber and desulfurized powder into a pulverizer for pulverization, passing through an 80-mesh sieve and mixing to obtain the first mixture;

[0056] Step S2: Add the modified asphalt emulsion into the stirring tank, stir at a speed of 2000r / min and a temperature of 150°C, and add the first mixture and pine tar prepared in step S1, and stir for 50min to obtain the first colloid;

[0057] Step S3: Add the first base liquid prepared in step S2 into a stirring tank, stir at a speed of 4000r / min and a temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com