Design and manufacture method of high-pressure hydrogen self-tightening combined seal

A combination of sealing and manufacturing method technology, applied in the direction of manufacturing tools, mechanical equipment, passing components, etc., can solve problems such as hydrogen embrittlement, leakage failure, and forced sealing leakage of the cone surface, so as to improve hydrogen embrittlement resistance and fatigue resistance , the effect of improving the stability of the organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A method for designing and manufacturing a high-pressure hydrogen-facing self-tightening combined seal, comprising the following steps:

[0059] S1, performing structural design on the metal structure; the material of the self-tightening metal structure 20 is austenitic stainless steel.

[0060] S2, machining the metal structure after structural design.

[0061] S3. Grinding and rolling the surface of the metal structure after machining to ensure that different parts of the metal structure meet the requirements of surface roughness. For example, when the metal structure is in service under alternating and pulse loads, the surface roughness requirements.

[0062] At the same time, due to the inhomogeneity of the material composition of austenitic stainless steel, there will be a local area with few austenitic elements, which is the unstable area of austenitic stainless steel. Deformation to induce martensitic transformation in the unstable region of austenitic stainl...

Embodiment 2

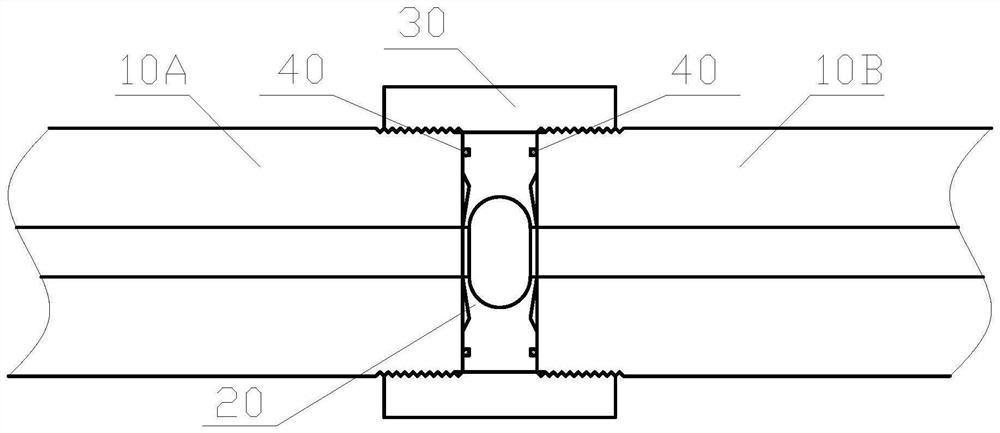

[0070] The overall connection structure of the high-pressure hydrogenation pipeline used in the hydrogenation station includes the following components: several sections of high-pressure hydrogenation pipelines, and sealing connectors for connecting the several sections of high-pressure hydrogenation pipelines in two phases.

[0071] The self-tightening metal structure 20 in this embodiment is a sealed connection between two sections of high-pressure hydrogen pipelines.

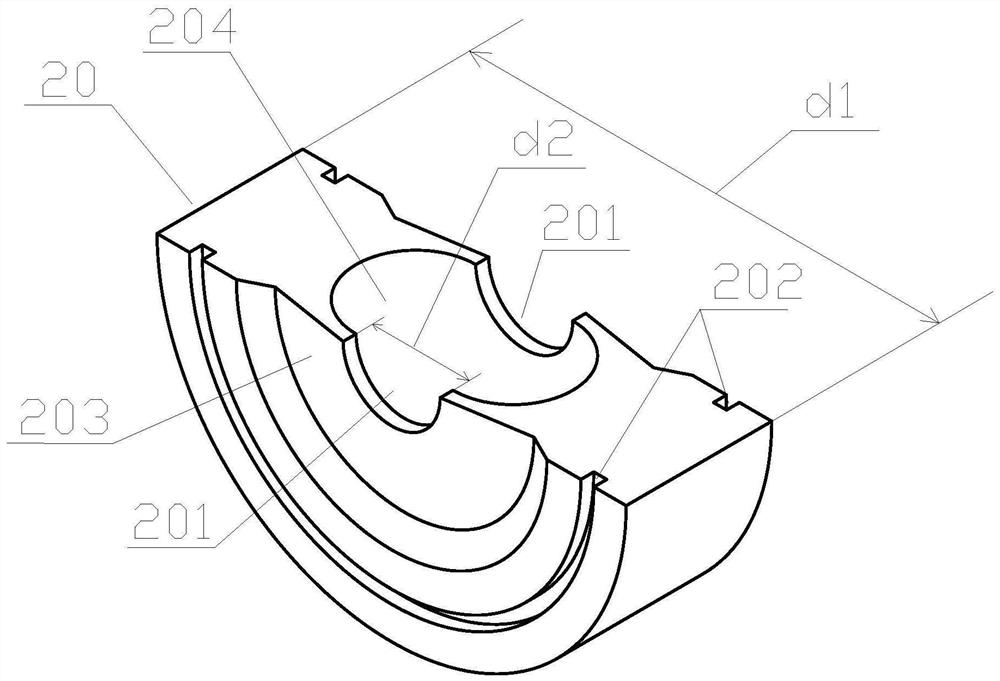

[0072] Depend on figure 2 As shown, the self-tightening metal structure 20 has a flat cylindrical shape as a whole, and both outer surfaces along the transmission direction of the high-pressure hydrogen pipeline are circular, and the diameters of the two outer surfaces are both d1, and the diameter d1 of the two outer surfaces is It is equal to the outer diameter d4 of the high-pressure hydrogen pipeline.

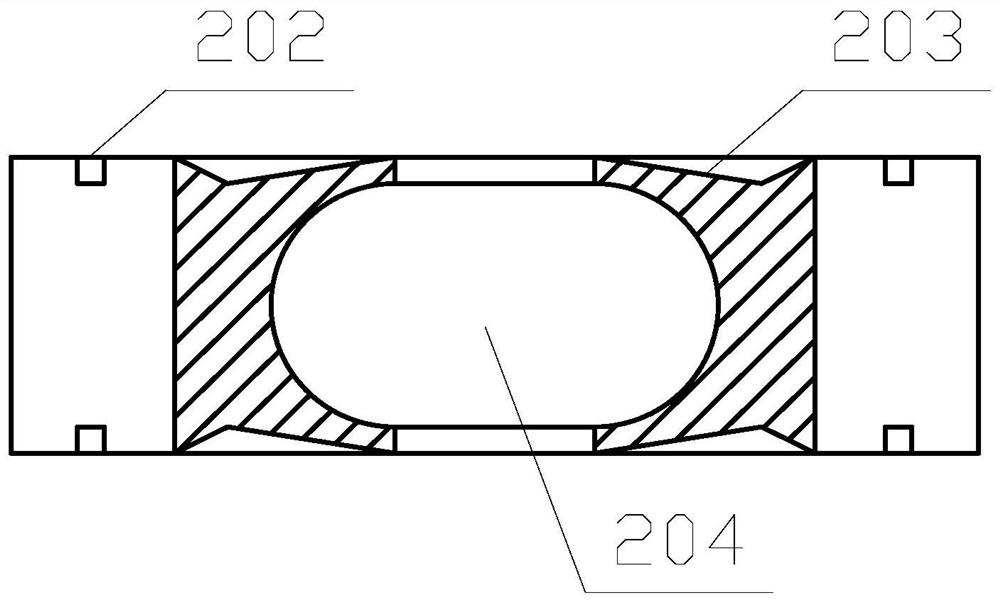

[0073] Depend on figure 2 with image 3 As shown, the self-tightening metal structure 20 is provid...

Embodiment 3

[0081] A method for designing and manufacturing a high-pressure hydrogen-facing self-tightening combined seal, comprising the following steps:

[0082] S1, carry out structural design on the self-tightening metal structure 20 in the second embodiment, the material of the self-tightening metal structure 20 in the second embodiment is austenitic stainless steel.

[0083] In step S1, the following steps are specifically included:

[0084] S11. Determine the service temperature and pressure of the self-tightening metal structure 20 according to the requirements of the hydrogen refueling station and according to the service temperature, pressure, specifications and other parameters of the high-pressure hydrogen pipeline.

[0085] S12, according to the service temperature and pressure of the self-tightening combined seal, select a rubber ring 40 of suitable material and size; wherein, the specific material of the rubber ring 40 can be selected from ethylene-propylene rubber, silicon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com