Through-hole reflow soldering equipment and machining method

A reflow soldering and reflow soldering machine technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of waste of resources, increase of artificial plug-ins and wave soldering processes, and high temperature resistance of components, to prevent high temperature damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] In order to make those skilled in the art better understand the technical solution of the present invention, the technical solution of the present invention will be described in detail below with reference to the drawings and specific embodiments, but the embodiments of the present invention are not limited thereto.

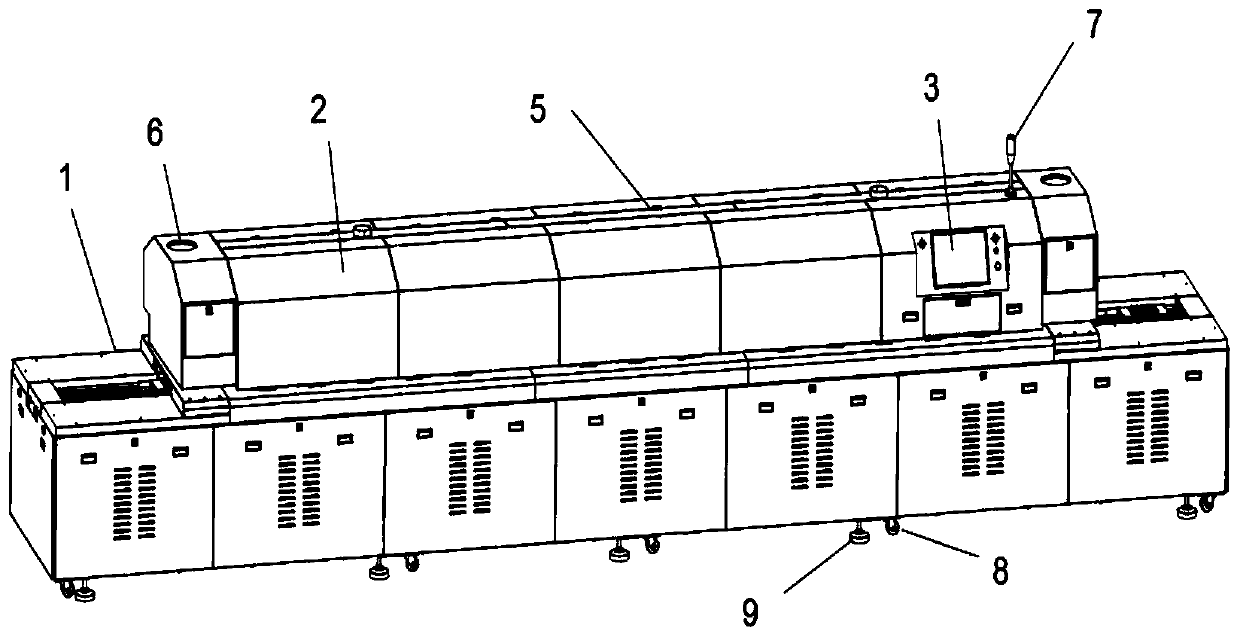

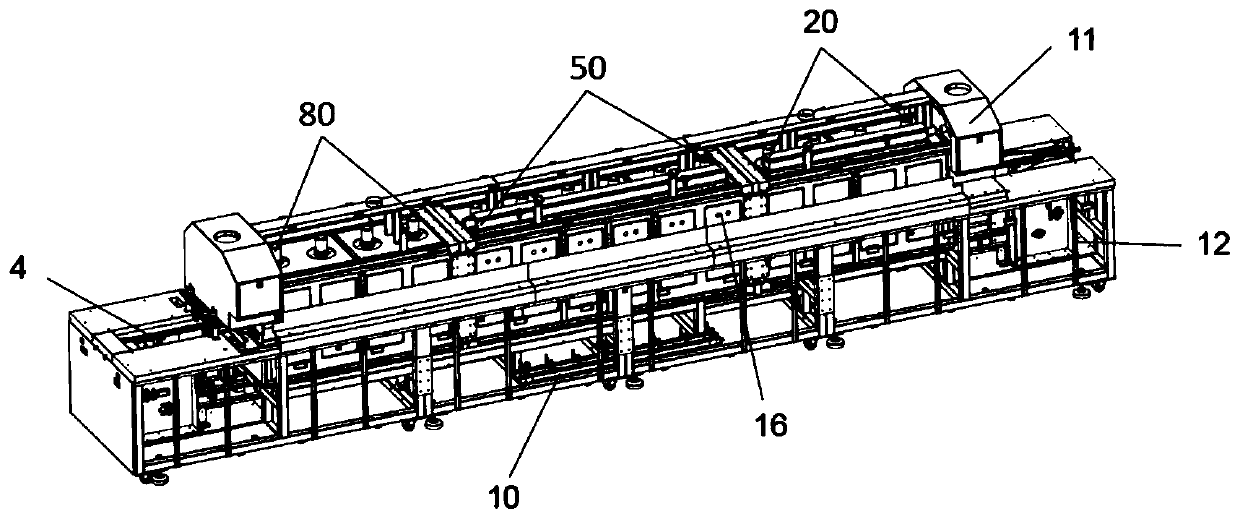

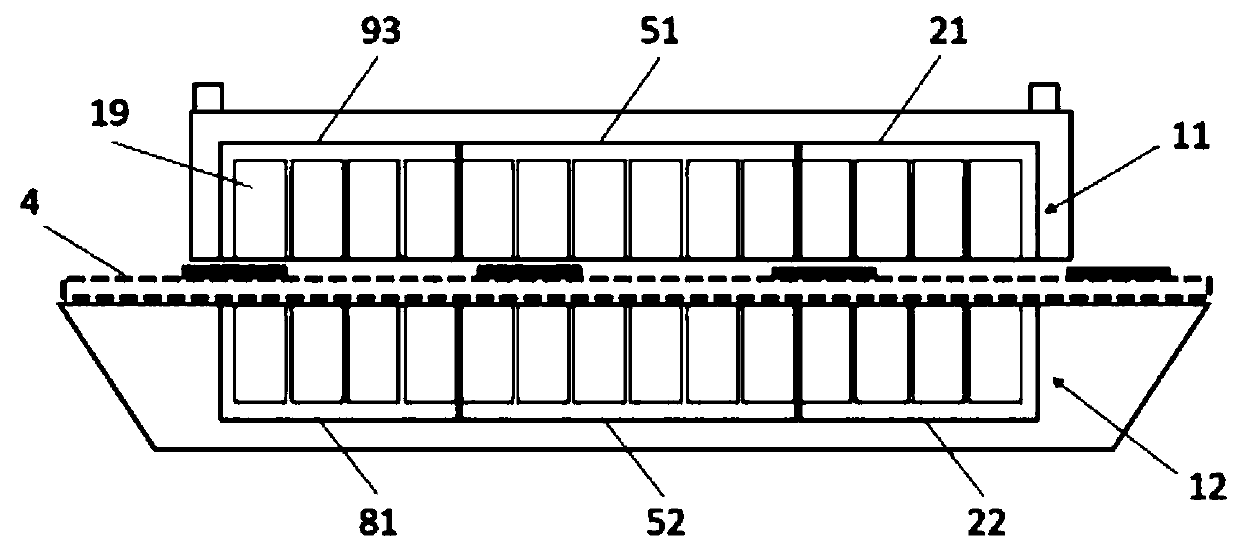

[0062] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 with Figure 12 Shown is the overall and partial structural view of the through-hole reflow soldering equipment of the present invention.

[0063] Such as Figures 1 to 4 As shown, it is a structural diagram of the through-hole reflow soldering equipment of the present invention. A through-hole reflow soldering equipment includes a through-hole reflow soldering machine 1, and the machine 1 is respectively set into three temperature zones along the horizontal direction, that is, the first Temperature zon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com