A wear-resistant super-amphiphobic self-cleaning film and its preparation method

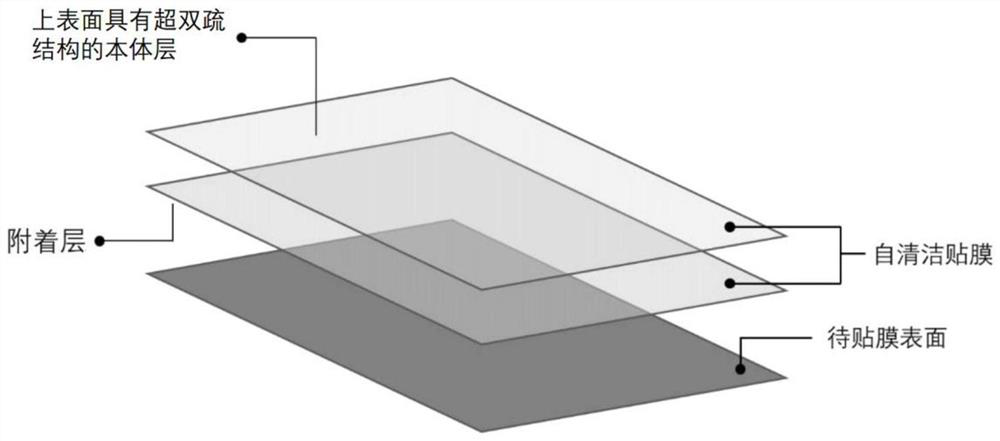

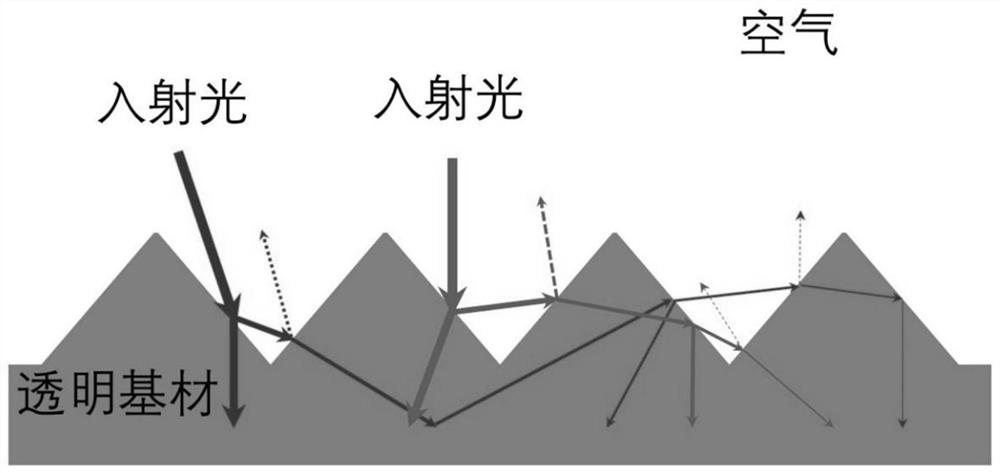

A self-cleaning, super-amphiphobic technology, used in glass manufacturing equipment, manufacturing tools, glass re-molding, etc., can solve the problems of super-amphiphobic surface processing, lack of mechanical strength, difficult maintenance, etc., to achieve high universality and versatility, enhanced light transmittance, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

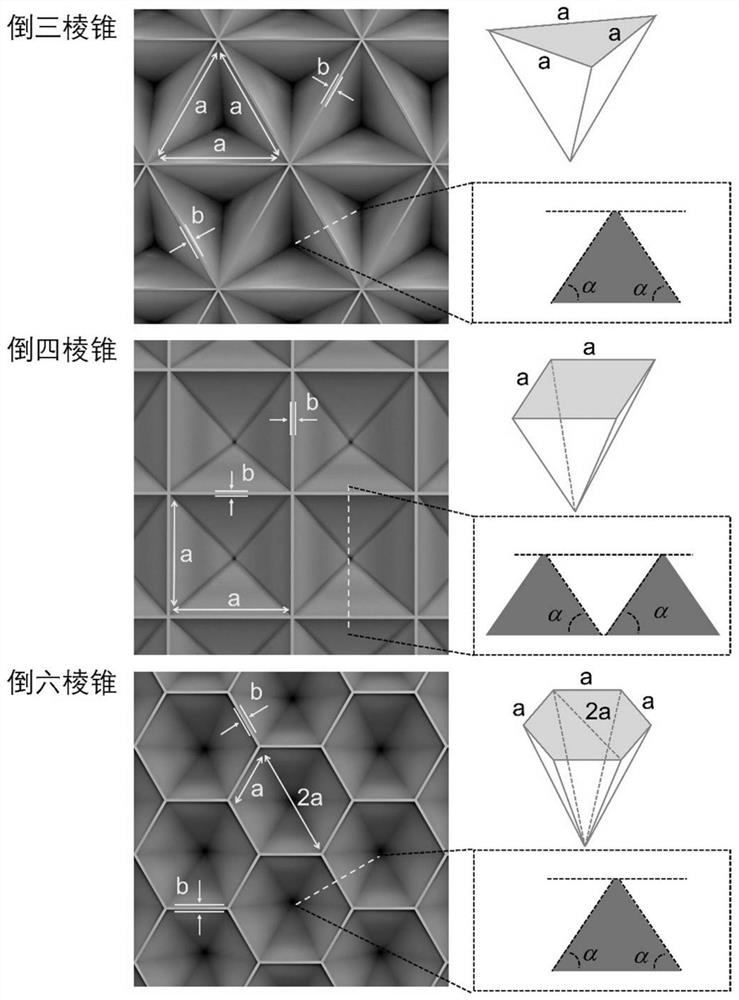

[0068] Preparation of microstructured glass by hot pressing method: place the shaped prefabricated glass sheet (thickness 170 μm) on the microstructure mold for hot pressing precision molding, such as Figure 4 shown. Place the prefabricated glass sheet on the mold and heat the temperature to 300°C; nitrogen gas is introduced to prevent the mold from being oxidized at high temperature. Through external pressurization and compression molding under 0.5MPa pressure, the microstructure of the mold surface is imprinted onto the surface of the prefabricated glass substrate. Finally, the pressure is released, and the molded prefabricated sheet is cooled to room temperature and released from the mold to obtain a surface with a microstructure. A glass plate with an inverted pyramid microstructure prepared by hot pressing, wherein the angle between the side wall and the bottom surface of the inverted pyramid is 45°, the side length of the bottom surface is 40 μm, and the distance betwe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com