Bisphenol acid-based epoxy resin emulsifier, and water-based emulsion and preparation method thereof

A bisphenolic acid-based epoxy resin and water-based emulsion technology, which is applied in the field of special emulsifiers and epoxy resins, can solve problems such as difficult to meet the requirements of green environmental protection, ecological environment hazards, etc., and achieve the effect that is conducive to sustainable development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

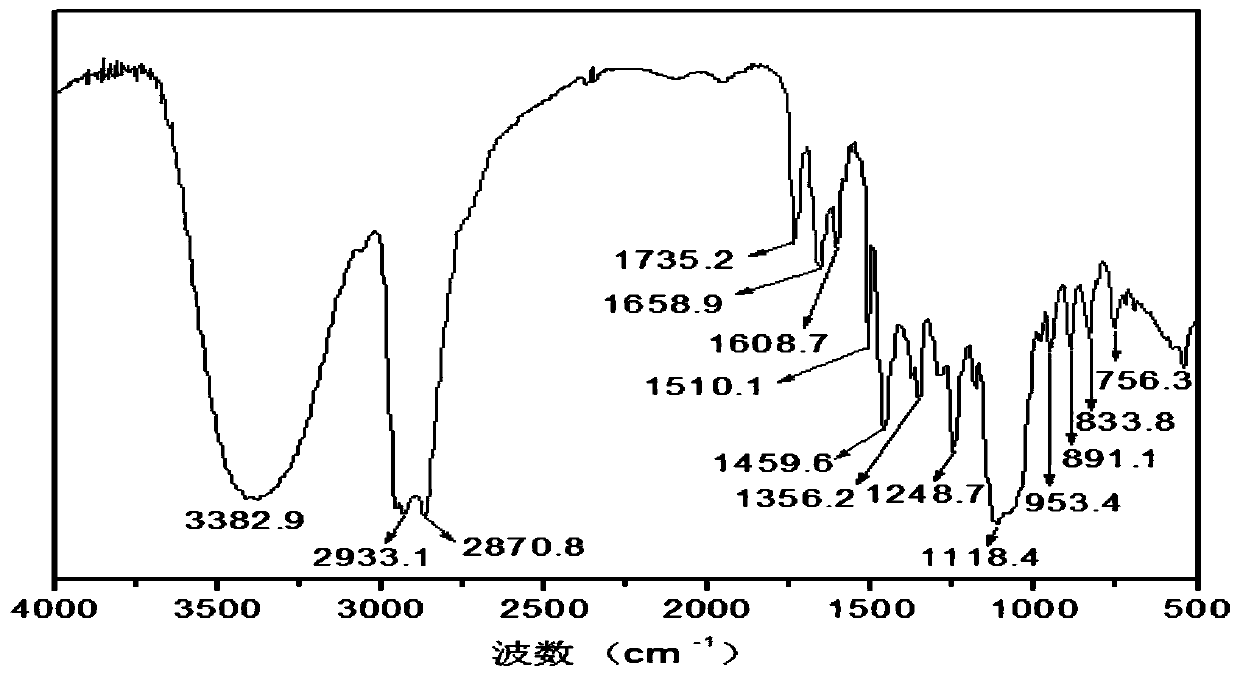

[0032] Preparation of emulsifier DPAE-nDOPO-(3-n) (MEA-PEGGE-MEA-PEGGE) (n=1):

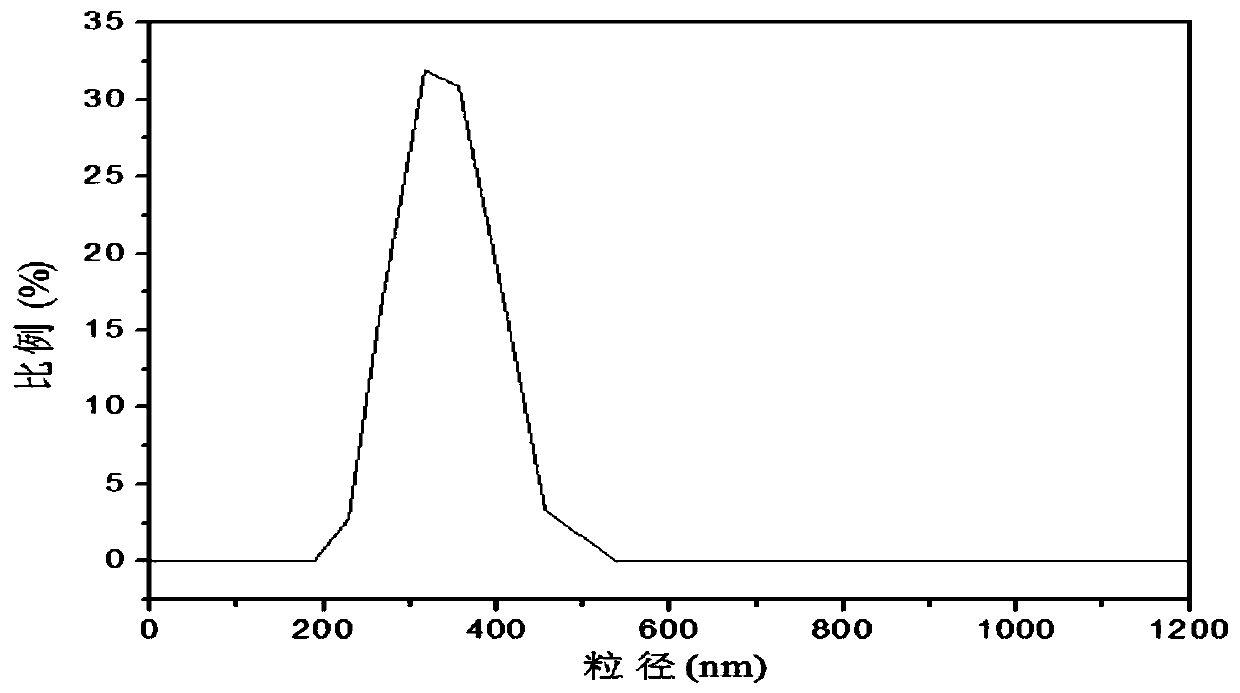

[0033] (1) Preparation of DPAE and DPAE-1DOPO adducts: first add bisphenolic acid (45.8g, 0.16mol) and epichlorohydrin (263.7g, 2.88) into a 1000ml three-necked flask with a stirring device and reflux condenser. mol), stir and heat for 30 minutes, add 3.61g of tetrabutylammonium bromide (TBAB) as a catalyst, gradually increase the temperature to 110°C, react for 8 hours, recover the excess epichlorohydrin by distillation under reduced pressure, and then add 150 Grams of ethyl acetate solvent, adjust the temperature to 25°C and add NaOH (19.2g, 0.48mol) solution (40% by mass NaOH aqueous solution) to close the loop for 2 hours, then transfer the reaction solution to a separatory funnel and add water to wash 3 Sub-to-neutral, stand still, separate the water layer, and distill the oil layer product under reduced pressure to obtain a light yellow semi-solid epoxy resin (DPAE, its epoxy value is 0.56). T...

Embodiment 2

[0050] Preparation of emulsifier DPAE-nDOPO-(3-n) (MEA-PEGGE-MEA-PEGGE) (n=2):

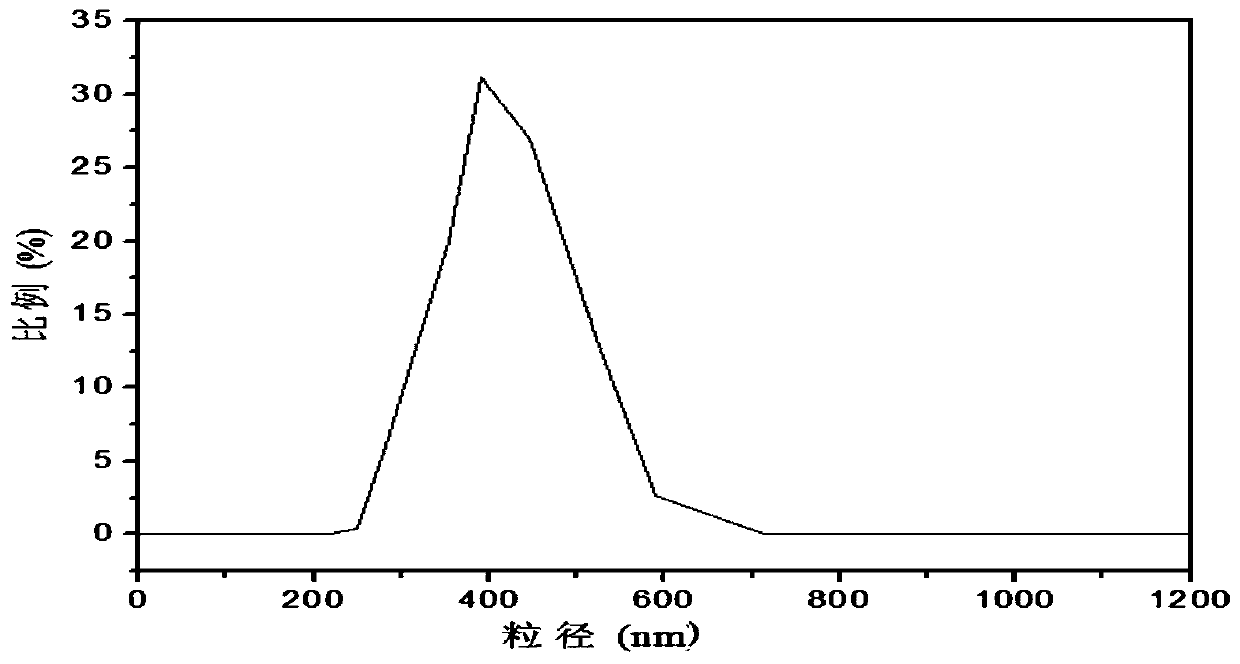

[0051] (1) Preparation of DPAE and DPAE-2DOPO adducts: first add bisphenolic acid (45.8g, 0.16mol) and epichlorohydrin (263.7g, 2.88) into a 1000ml three-necked flask with a stirring device and reflux condenser. mol), stir and heat for 30 minutes, add 3.61g of tetrabutylammonium bromide (TBAB) as a catalyst, gradually increase the temperature to 110°C, after reacting for 8 hours, recover the excess epichlorohydrin by distillation under reduced pressure, and then add 150 Grams of ethyl acetate solvent, adjust the temperature to 25°C and add NaOH (19.2g, 0.48mol) solution (40% by mass NaOH aqueous solution) to close the loop for 2 hours, then transfer the reaction solution to a separatory funnel and add water to wash 4 Sub-to-neutral, stand still, separate the water layer, distill the oil layer product under reduced pressure to obtain a light yellow semi-solid epoxy resin (DPAE, the epoxy value measure...

Embodiment 3

[0063] Preparation of emulsifier DPAE-nDOPO-(3-n) (MEA-PEGGE-MEA-PEGGE) (n=1.5):

[0064] (1) Preparation of DPAE and DPAE-1.5DOPO adducts: first add bisphenolic acid (45.8g, 0.16mol) and epichlorohydrin (263.7g, 2.88mol), stir and heat for 30 minutes, add 3.65g of tetrabutylammonium bromide (TBAB) as a catalyst, gradually increase the temperature to 110°C, react for 8 hours, recover the excess epichlorohydrin by distillation under reduced pressure, and then add 150 grams of ethyl acetate solvent, adjust the temperature to 25°C and add NaOH (19.2g, 0.48mol) solution (40% by mass NaOH aqueous solution) to close the loop for 2 hours, then transfer the reaction solution to a separatory funnel and add water to wash 3 times to neutral, let stand, separate the water layer, distill the oil layer product under reduced pressure to obtain a light yellow semi-solid epoxy resin (DPAE, its epoxy value is 0.56). Take 10.71g of bisphenolic acid-based epoxy resin (DPAE), 6.48g of DOPO, 1.20g of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com