Low-nitrogen combustor

A low-nitrogen burner and combustion cylinder technology, applied in the direction of burners, gas fuel burners, combustion methods, etc., can solve the problems of multiple nitrogen oxides, achieve uniform temperature, complete combustion, and improve the effect of disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

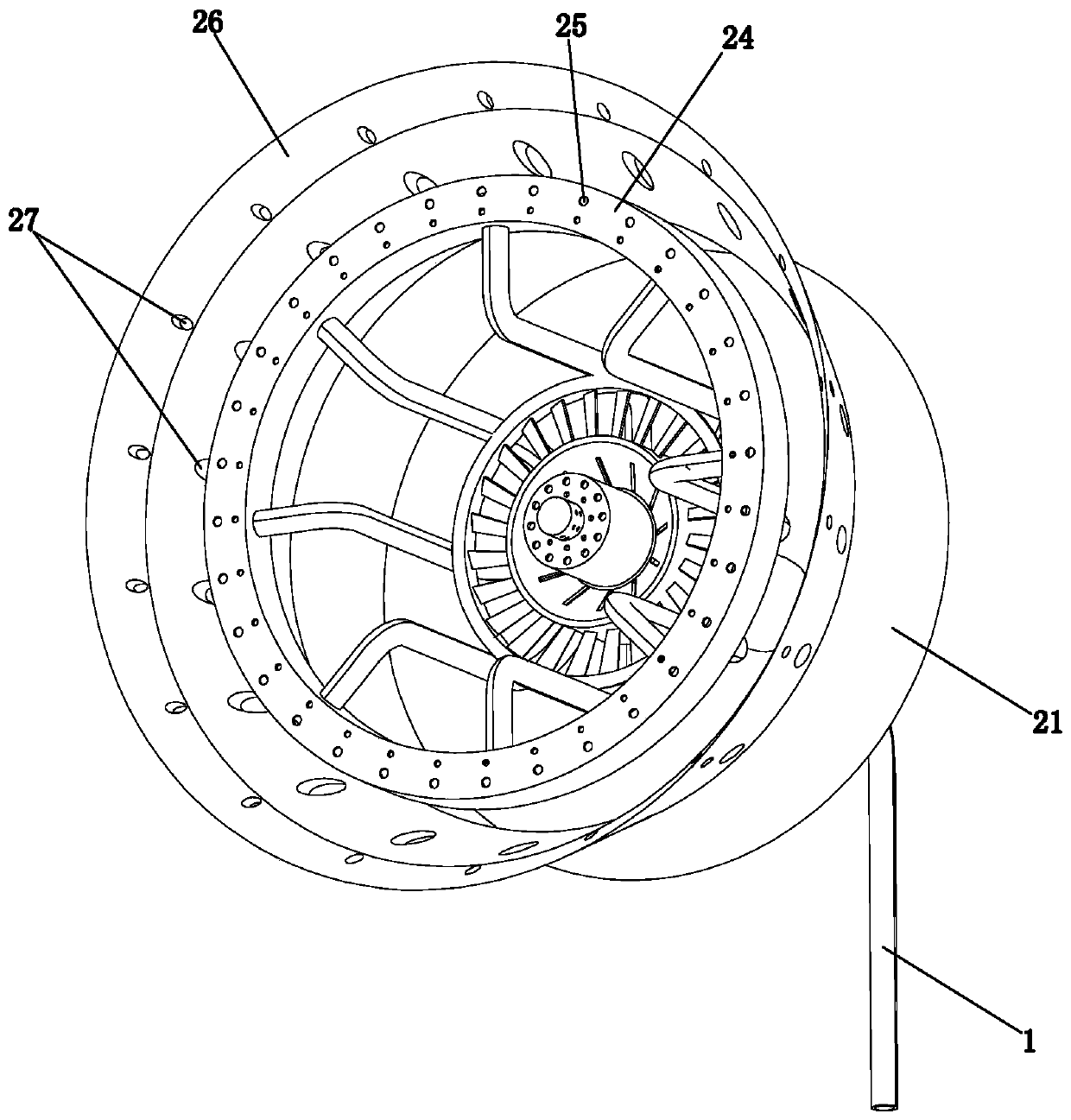

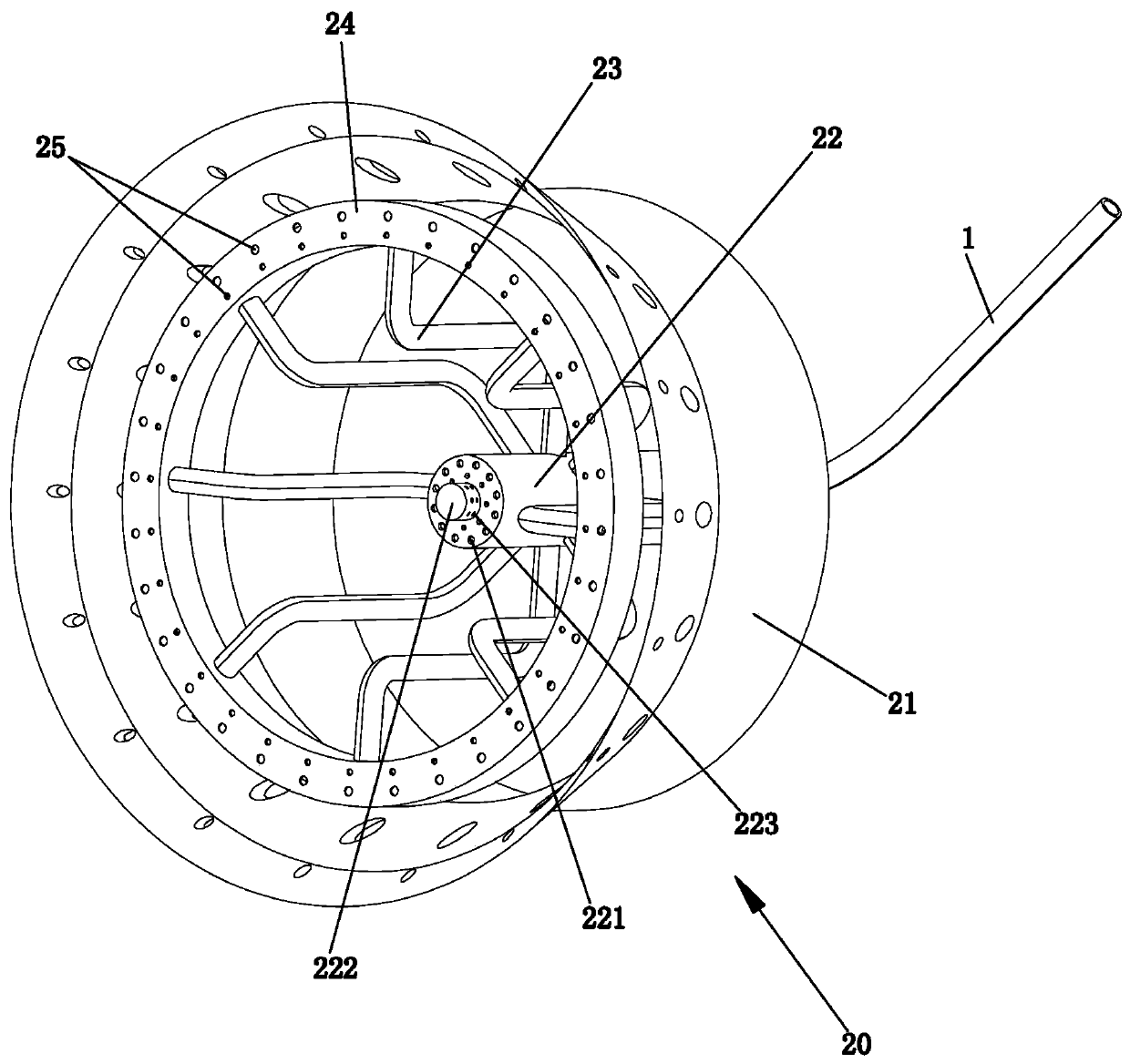

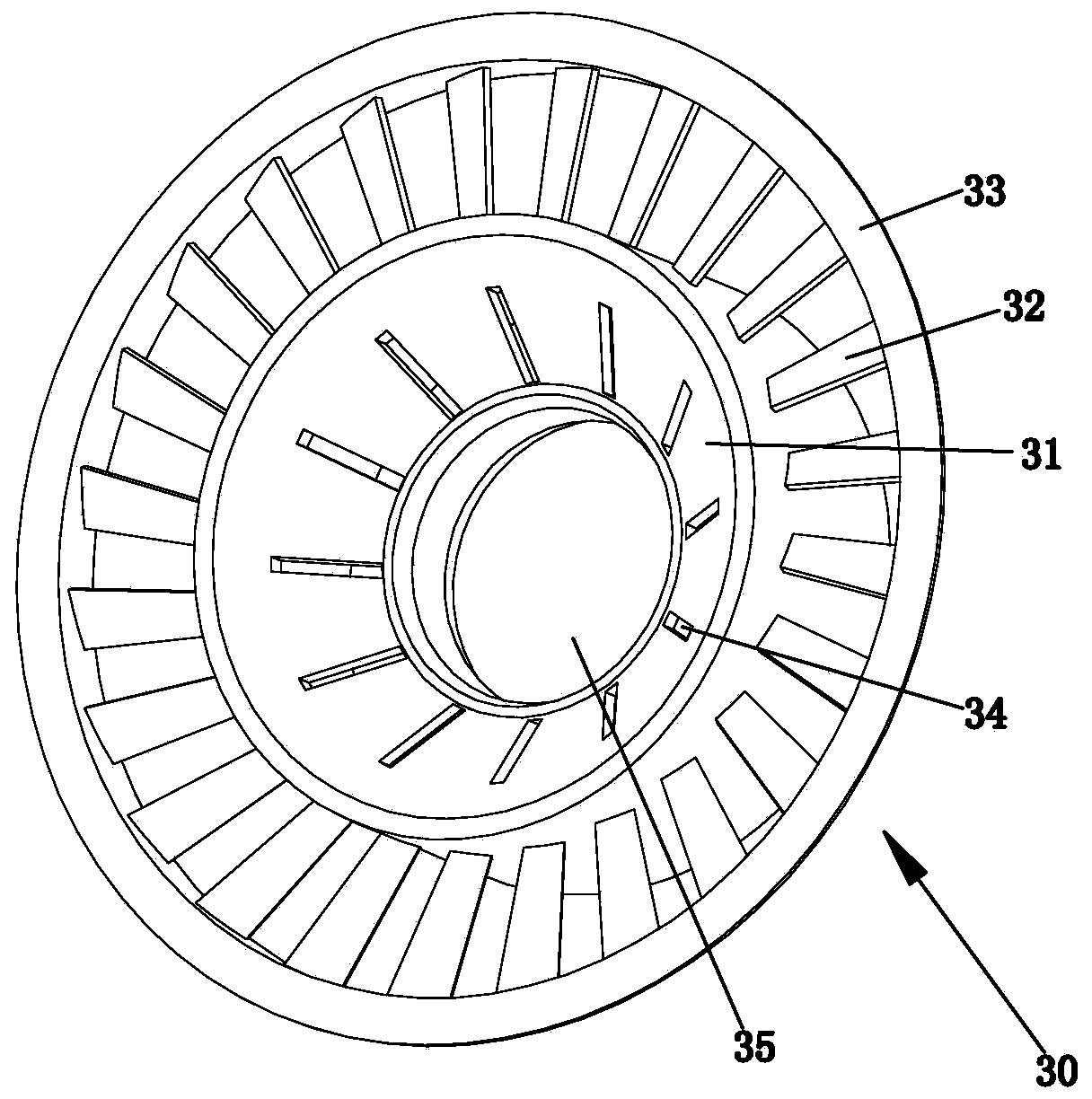

[0031] Please check Figure 1 to Figure 5 , a preferred embodiment of the low-nitrogen burner, the low-nitrogen burner, which includes a hollow combustion cylinder 10, a gas injection mechanism 20 and a swirl mechanism 30.

[0032] like Figure 4 As shown, the combustion cylinder 10 includes an upper cylinder 11 and a lower cylinder 12 , the upper cylinder 11 and the lower cylinder 12 are connected by a stepped surface 13 , and the diameter of the upper cylinder 11 is larger than that of the lower cylinder 12 . The bottom opening of the lower cylinder 12 is an air inlet, that is, an air and gas inlet, and the top opening of the upper cylinder 11 is an air outlet for combustion products.

[0033] The gas injection mechanism 20 is fixed in the combustion cylinder 10, which includes a hollow injection body 21, a main gas distribution pipe 22, several surrounding gas distribution pipes 23 and an annular outlet pipe 24, and the main gas distribution pipe 22 is located in the injec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com