Boiler smoke treatment device

A treatment device, boiler flue gas technology, applied in the direction of climate sustainability, greenhouse gas reduction, fixed tubular conduit assembly, etc., can solve the problems of poor sulfur dioxide treatment effect, low dust treatment efficiency, inconvenient dust precipitation cleaning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

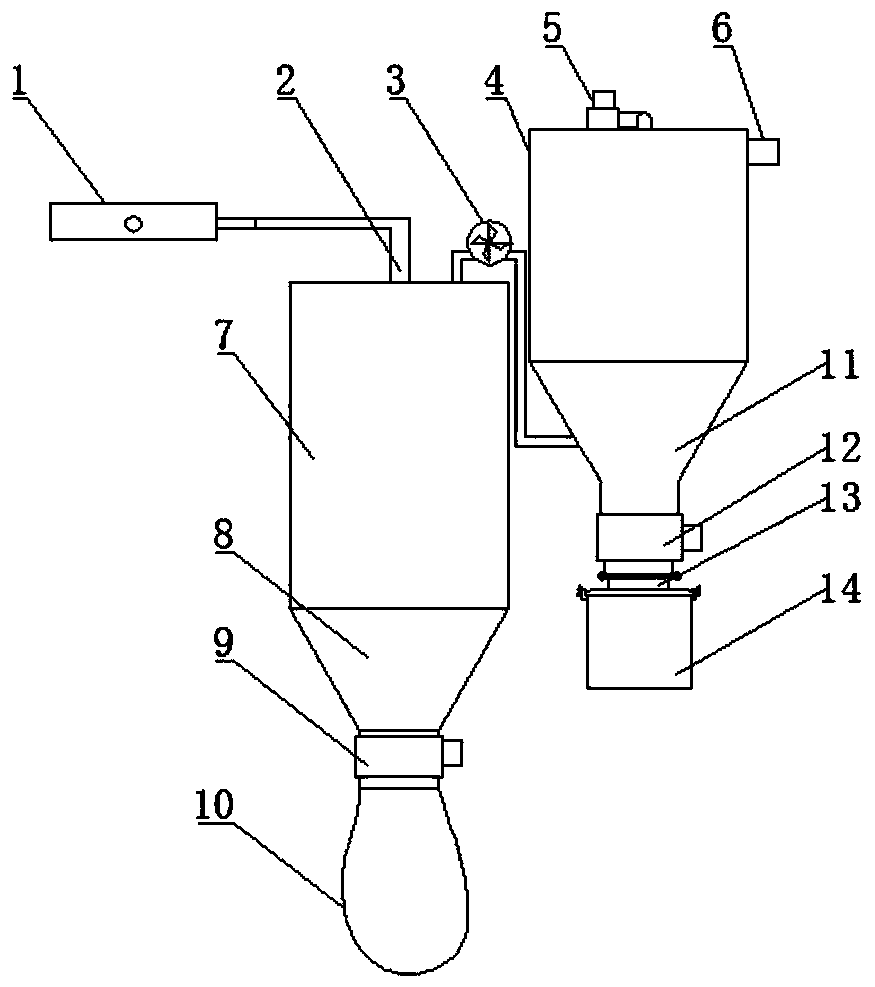

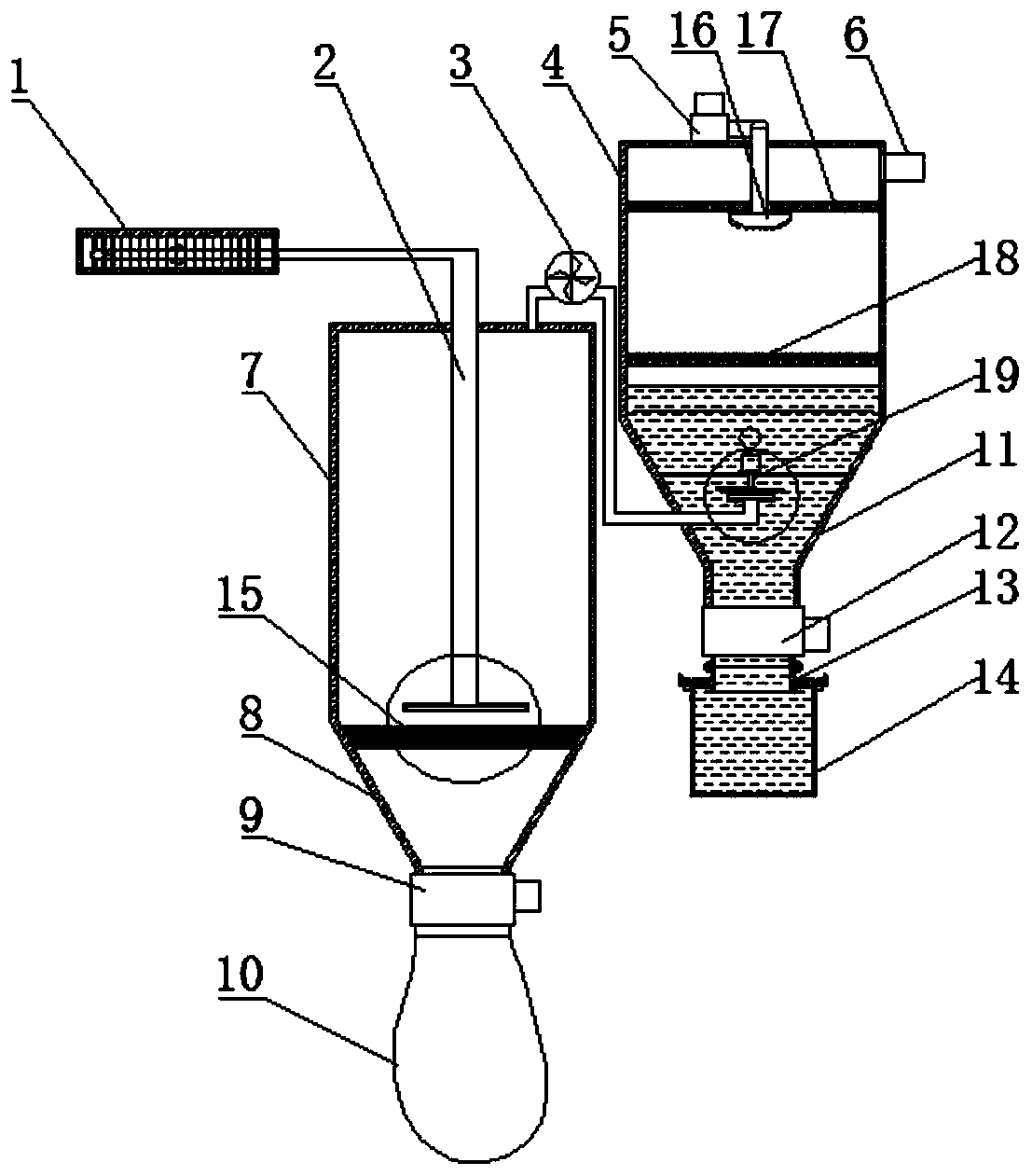

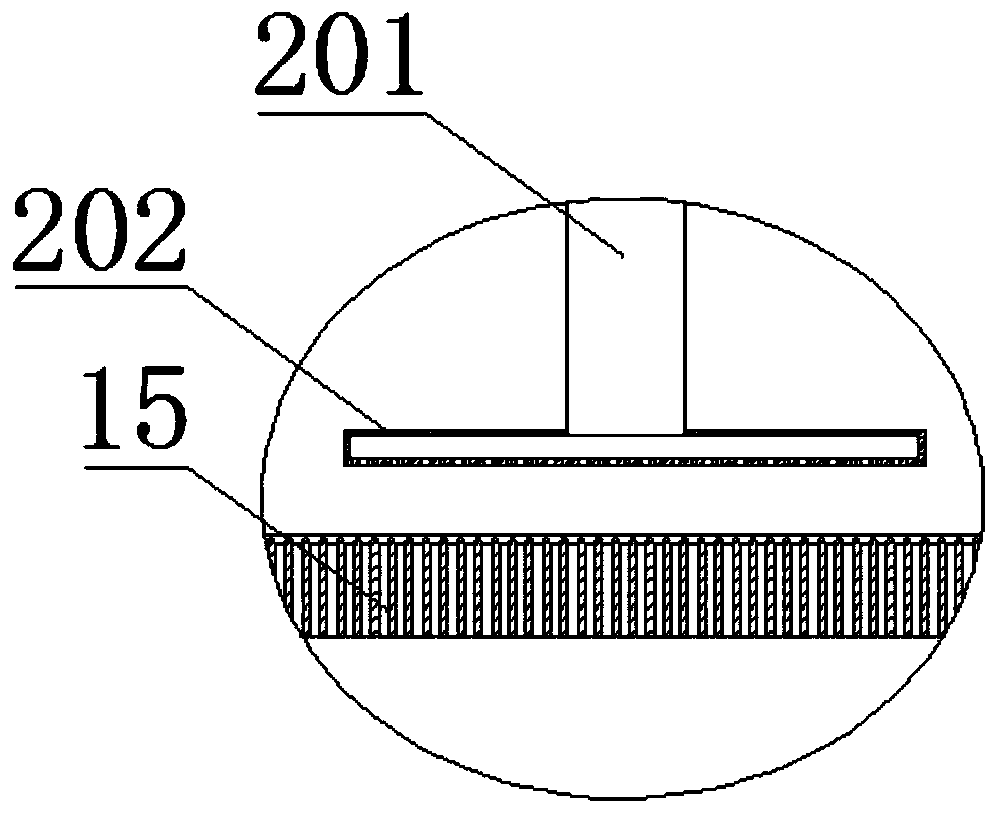

[0027] Example 1, please refer to figure 1 and figure 2, comprising a heat recovery device 1, a filter box 4 and a dust removal box 7, the intake end of the heat recovery device 1 is connected to the exhaust pipe of the boiler through a pipe to realize the collection of boiler flue gas and the recovery of heat in the flue gas, and The gas outlet end of the heat recovery device 1 is connected to a smoke inlet mechanism 2 through a pipe, and the heat recovery device 1 sends the flue gas after heat recovery to the smoke inlet mechanism 2, and the smoke inlet mechanism 2 is connected to the upper end of the dust removal box 7, and the dust removal box 7 The lower end of the dust collection hopper is integrally provided with an ash collecting hopper 8, which realizes the collection of deposited dust. The lower port of the ash collecting hopper 8 is provided with a first electric valve 9, and the lower port of the first electric valve 9 is provided with a fixed cover. There is a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com