Vortex light-based micro-vibration detection device for constant-rotating-speed rotating object

A detection device and constant speed technology, applied in measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve problems such as difficult measurement and frequency change, and achieve the effects of easy control, rapid response and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] specific implementation plan

[0039] In the present invention, the superposition vortex beam is used as the detection carrier, and the specific implementation steps are as follows:

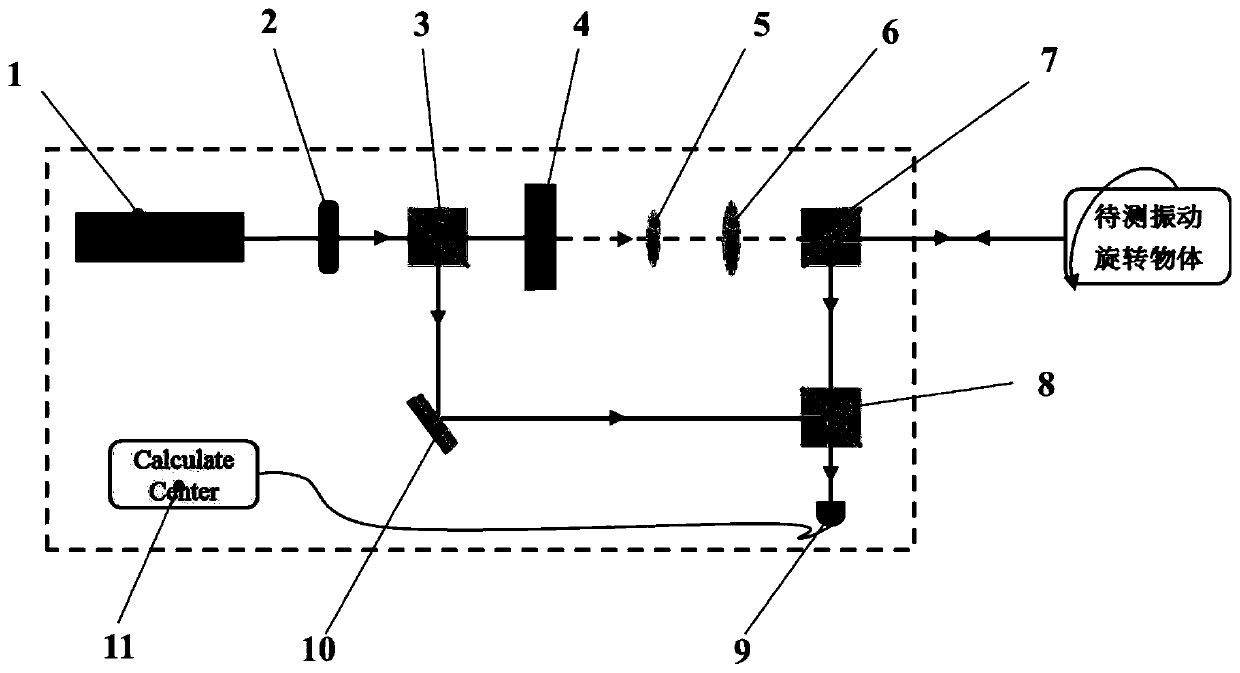

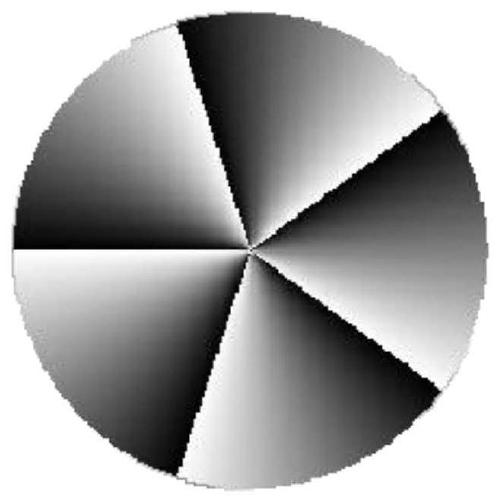

[0040] First, the laser (1) generates a laser beam with a wavelength of 632.8nm, which becomes horizontally polarized light after passing through the polarizer (2), and then is divided into two beams by the beam splitter (3), and one beam is used as the detection light and projected on the spiral phase plate ( 4), another beam is directed to the plane reflector (10) as local oscillation light, and the basic structure of the spiral phase plate is as follows figure 2 shown.

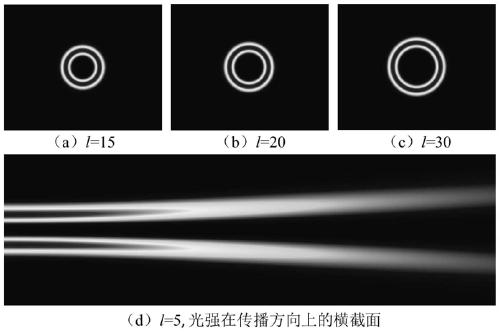

[0041] The light beam passing through the spiral phase plate (4) becomes a vortex light with a specific topological charge. The lens groups (5) and (6) expand and collimate the vortex beam, and then pass through the beam splitting prism (7) to irradiate to For the rotating object to be tested, the light beam reflecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com