A pipeline body safety management method

A technology of safety management and pipeline, applied in the field of pipeline management, can solve the problems of inability to perform intelligent evaluation, comprehensive analysis and evaluation, and inability to manage, etc., to achieve the effect of solving data islands, making up for a huge amount of work, and avoiding discrepancies in film reviews

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

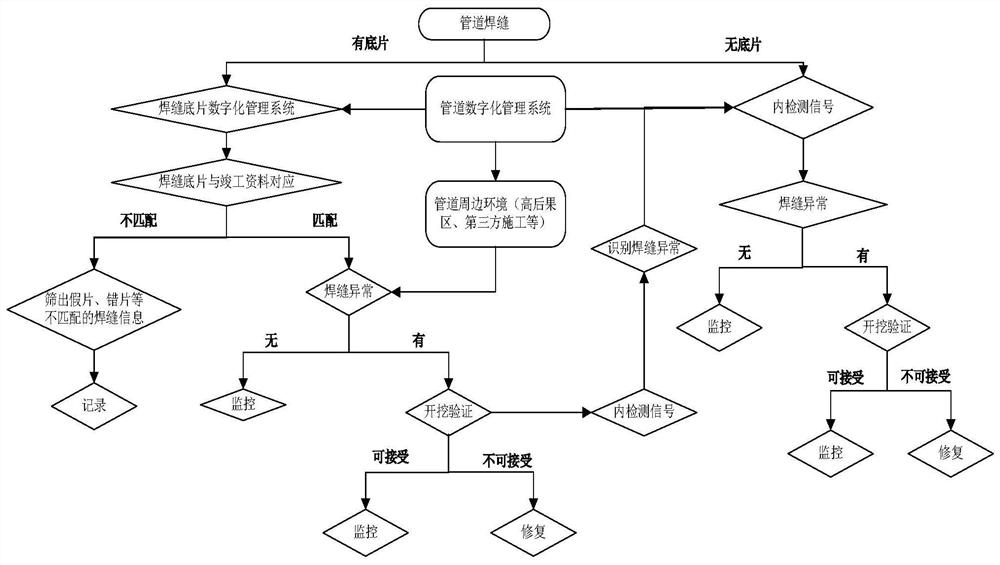

[0031] see Figure 1-2 , the pipeline body safety management method based on weld intelligent evaluation and big data comprehensive analysis in this embodiment includes the following steps:

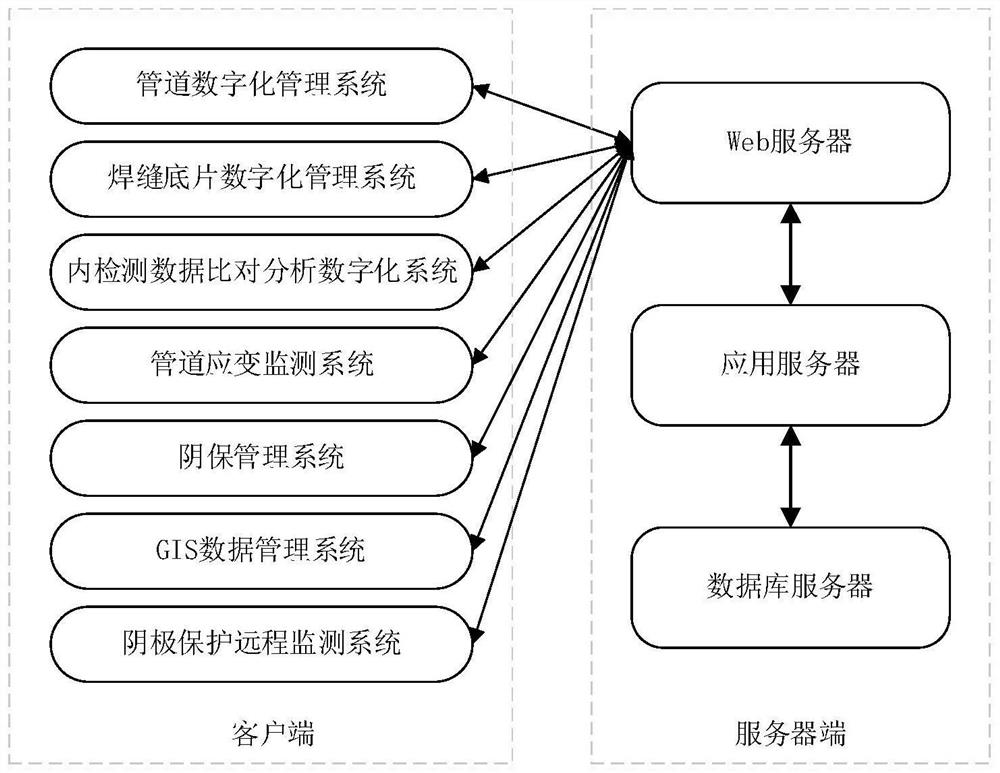

[0032] Step 1, the existing data management systems are all independent of each other, using the Internet-based database sharing method (system structure such as figure 2As shown), the pipeline digital management system is connected with the weld film digital management system to realize data sharing. Among them, the pipeline digital management system is used to realize the management of information such as completion data, third-party construction, and high-consequence areas, and the weld film digitalization The management system realizes the management of the weld electronic film;

[0033] Step 2. Align the weld negatives with the weld information of the as-built data according to the position information and weld number, so as to realize the following functions:

[0034] (1) Screen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com