Phosphoric acid etching agent and preparation method thereof

A phosphoric acid etchant and phosphoric acid technology, used in pharmaceutical formulations, dental preparations, press mold cups, etc., can solve problems such as caking and poor shape, and achieve the effects of extending storage period, improving surface properties and reducing surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0041] A phosphoric acid etchant, said phosphoric acid etchant is mainly made of phosphoric acid, fumed silica, glycerin, sodium lauryl ether sulfate, polyethylene glycol, methylene blue, purified water, said phosphoric acid The parts by weight of phosphoric acid in the etchant are 350 parts by weight, the parts by weight of fumed silica are 100 parts, the parts by weight of glycerin are 100 parts, the parts by weight of sodium lauryl ether sulfate are 10 parts, polyethylene glycol The parts by weight of alcohol are 20 parts by weight, the parts by weight of methylene blue are 0.01 parts by weight, and the parts by weight of purified water are 250 parts by weight.

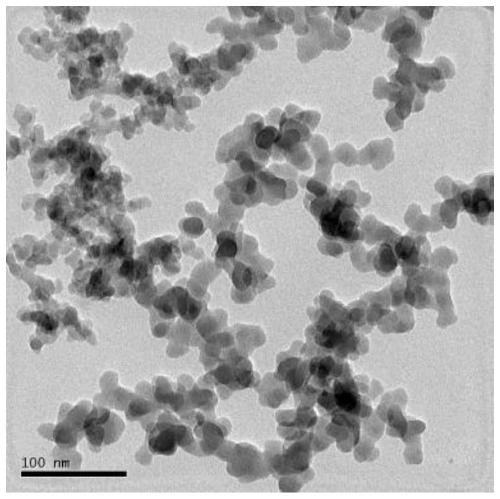

[0042]A phosphoric acid etching agent described in this embodiment, the average primary particle size of fumed silica in the phosphoric acid etching agent is 7-40nm, the aggregate particle size is 200-300nm, and the specific surface area is 200m 2 / g, SiO 2 Content ≥ 99.0%.

[0043] A phosphoric acid etching agen...

specific Embodiment approach 2

[0056] A phosphoric acid etchant, said phosphoric acid etchant is mainly made of phosphoric acid, fumed silica, glycerin, sodium lauryl ether sulfate, polyethylene glycol, methylene blue, purified water, said phosphoric acid The parts by weight of phosphoric acid in the etching agent are 380 parts by weight, the parts by weight of fumed silica are 250 parts by weight, the parts by weight of glycerin are 250 parts, the parts by weight of sodium lauryl ether sulfate are 50 parts, polyethylene glycol The parts by weight of alcohol are 50 parts by weight, the parts by weight of methylene blue are 1 part by weight, and the parts by weight of purified water are 400 parts by weight.

[0057] A phosphoric acid etching agent described in this embodiment, the average primary particle size of fumed silica in the phosphoric acid etching agent is 7-40nm, the aggregate particle size is 200-300nm, and the specific surface area is 200m 2 / g, SiO 2 Content ≥ 99.0%.

[0058] A phosphoric acid...

specific Embodiment approach 3

[0070] A phosphoric acid etchant, said phosphoric acid etchant is mainly made of phosphoric acid, fumed silicon dioxide, glycerin, sodium lauryl ether sulfate, polyethylene glycol, methylene blue, purified water, and its parts by weight are respectively 350-380 parts of phosphoric acid, 100-250 parts of fumed silica, 100-250 parts of glycerin, 10-50 parts of sodium lauryl ether sulfate, 20-50 parts of polyethylene glycol, 0.01-1 Parts of methylene blue, 250-400 parts of purified water.

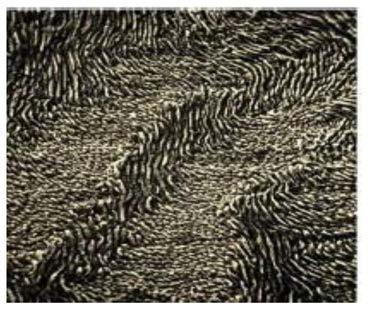

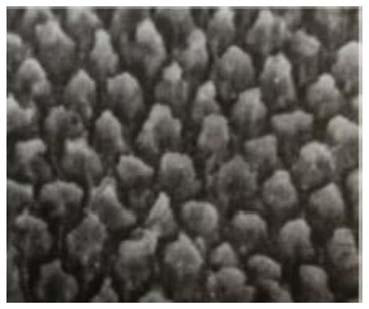

[0071] A phosphoric acid etchant described in this embodiment is used for intraoral restoration or orthodontic treatment. The corrosion of the etchant is used to treat the surface of restorations such as tooth bodies, metals, and ceramics to remove contamination layers, roughness, etc. surface and improve its surface properties. Polyethylene glycol is a good solubilizer, stable and not easy to deteriorate. It can adjust the consistency of the paste and prolong the storage period of the paste;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com