Preparation method and application of P-modified g-C3N4 catalyst

A technology of g-c3n4 and catalyst is applied in the field of photocatalysis to achieve the effects of simple preparation, improved catalytic activity and enhanced absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

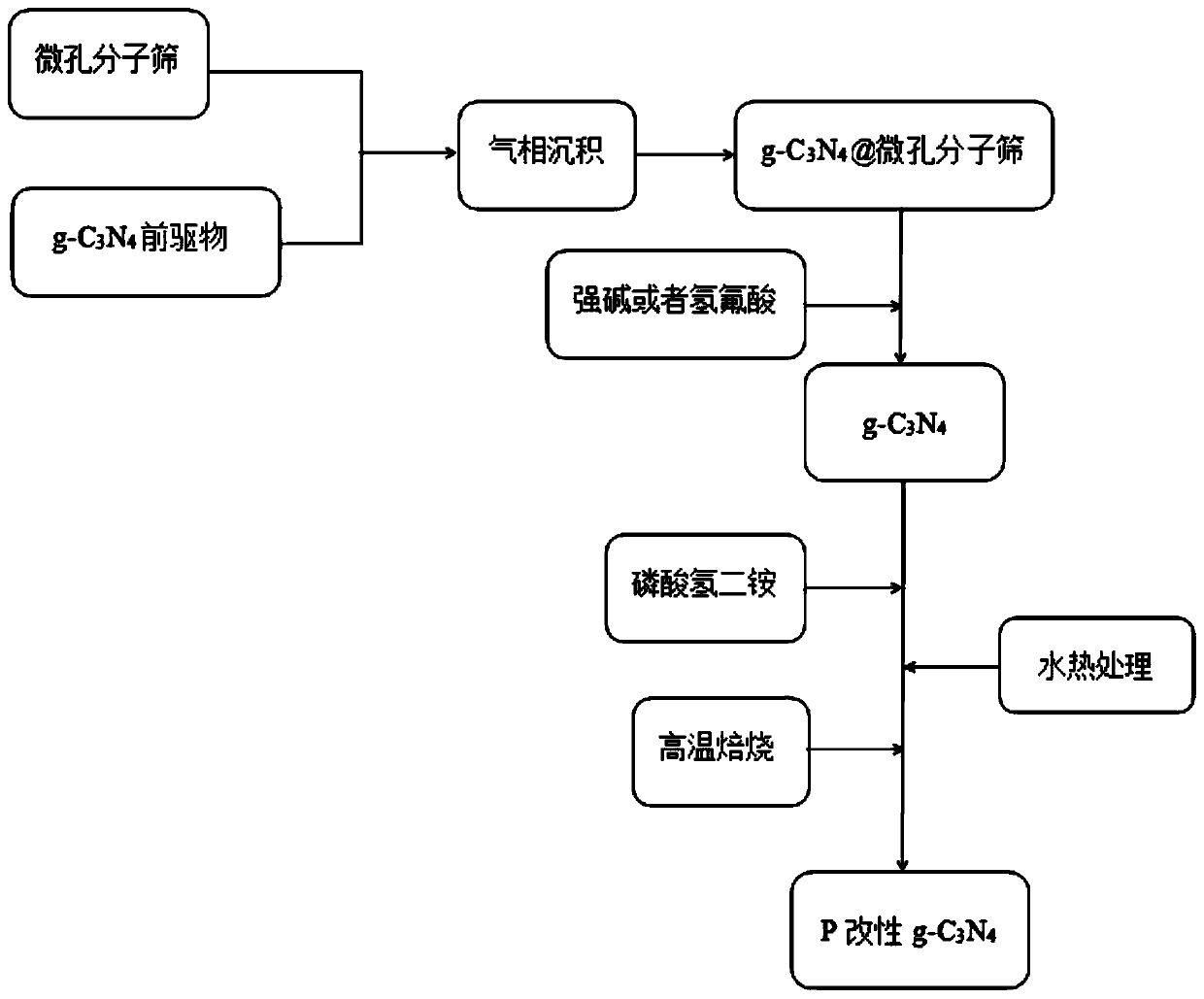

[0029] Preparation of g-C by Vapor-Phase Deposition Method Using Staged Roasting 3 N 4 : Put 50g of melamine into the crucible, then spread 0.5g of microporous Beta molecular sieve on the surface of the melamine, put a cover on the top of the crucible, heat from room temperature to 320°C at a heating rate of 5°C / min, and keep the temperature for 3h. Then heated to 550 °C at a heating rate of 5 °C / min, kept for 1 h, and naturally cooled to room temperature to prepare g-C 3 N 4 @Microporous Beta Molecular Sieve. Weigh 1.0g of g-C 3 N 4 @Microporous Beta molecular sieve was added to 10mL of 10M NaOH solution to remove the microporous molecular sieve, treated at 80°C for 4h, filtered, rinsed with deionized water until neutral, and dried at 100°C for 10h to obtain a light yellow solid , labeled g-C 3 N 4 (Beta)-1, the specific preparation process is as follows figure 1 shown.

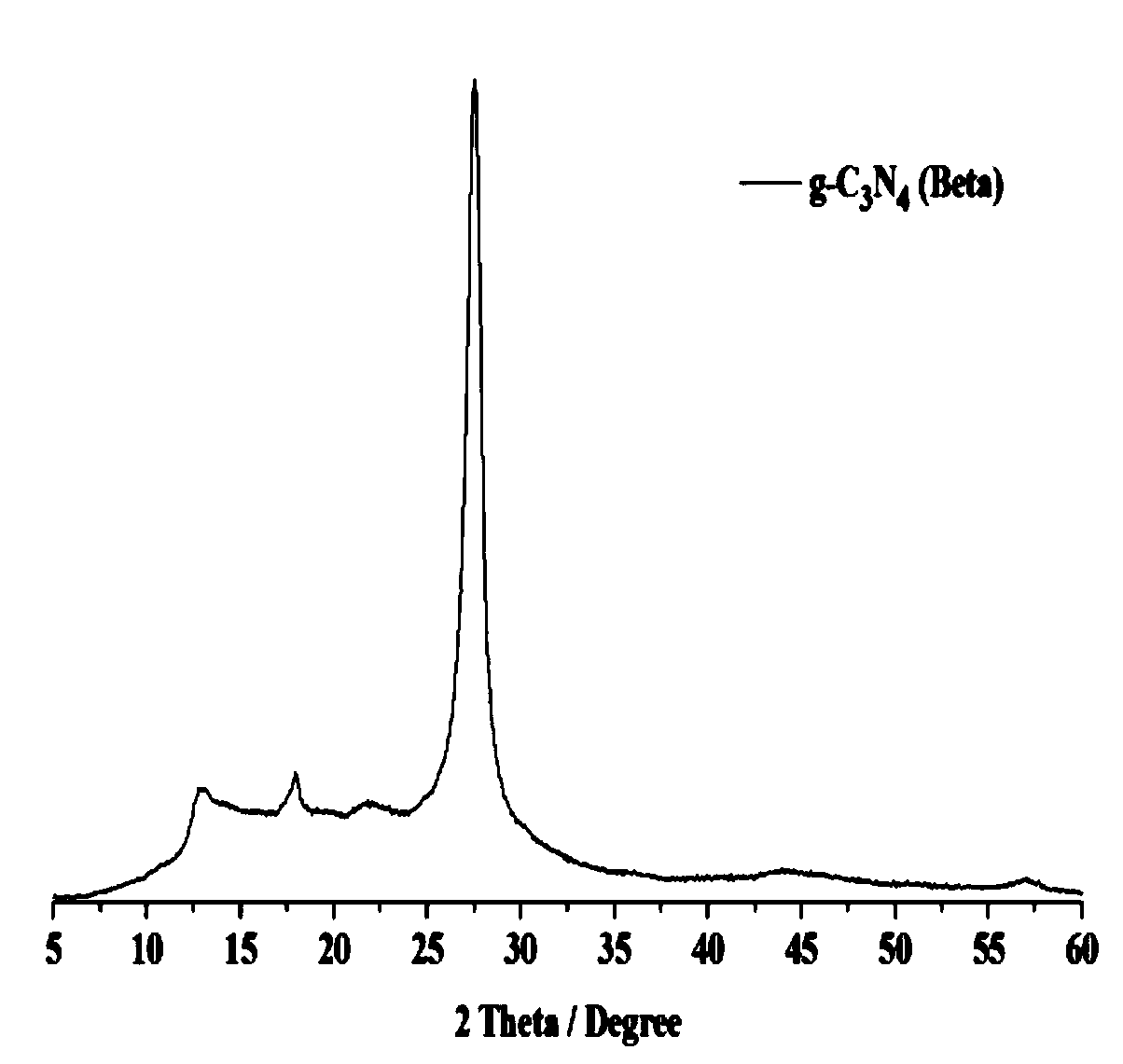

[0030] Characterized by XRD, the specific results are shown in figure 2 . from figure 2 It ...

Embodiment 2

[0032] The preparation process is the same as in Example 1, the only difference is that the quality of the microporous Beta molecular sieve is 5.0g, and the obtained light yellow solid is marked as g-C 3 N 4 (Beta)-2.

Embodiment 3

[0034] The preparation process is the same as in Example 1, the only difference is that the quality of the microporous Beta molecular sieve is 0.05g, and the obtained light yellow solid is marked as g-C 3 N 4 (Beta)-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com