Low-cost large-scale-application radiation refrigeration thin film and preparing method

A radiation refrigeration and large-area technology, applied in refrigerators, refrigeration and liquefaction, devices for coating liquid on surfaces, etc., can solve problems such as difficult application and promotion, high cost, and difficult processing of micro-nano structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

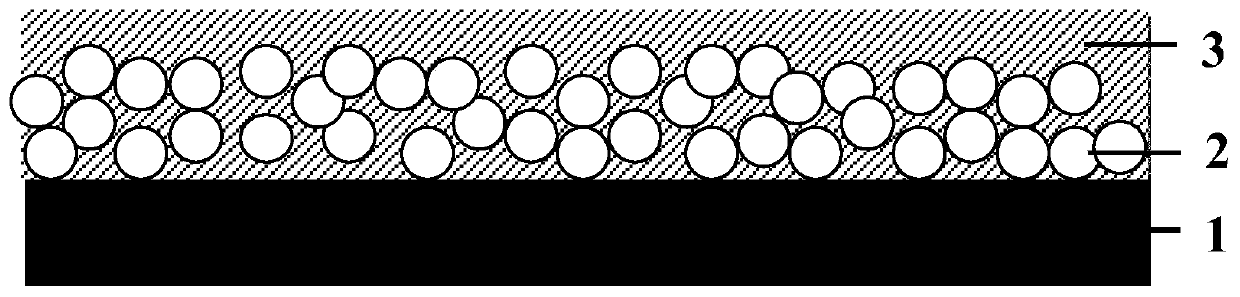

[0012] Example 1: First configure the precursor solution: (a) PDMS solution: mix polydimethylsiloxane prepolymer A and crosslinking agent B in chloroform at a mixing ratio of 10:1:20, Then stir it with magnetic force to make it evenly mixed, and let it stand for use. (b) Particle dispersion: 20nm Si 3 N 4 Particles were dispersed in deionized water, ultrasonically stirred for 20 minutes, and magnetically stirred for 3 minutes before use. Then start the sample preparation: put the evaporated silver glass substrate with a thickness of 100nm on the surface of the flat plate of the film scraper, then spray the configured particle dispersion on the aluminum foil, and then place it in a fume hood to dry naturally for 20 minutes. Then invert an appropriate amount of the prepared PDMS solution on the initial end of the film scraping coating, and select a 6um thick wire rod to scrape coating at a certain speed. Put the coated film into an oven and cure it at 100 degrees Celsius for ...

Embodiment 2

[0013] Embodiment 2: The preparation method of the precursor solution of organic matter and particulate matter is the same as that of Embodiment 1, and SiO with a particle size of 100 nm is used 2 . Then start the sample preparation: place the evaporated gold glass substrate with a thickness of 150nm on the surface of the flat plate of the film scraper, spray the configured particle dispersion on the aluminum foil, and then place it in a fume hood to dry naturally for 20 minutes. Then the sample was placed on the suction cup of the spin coater, and the prepared PDMS solution was spin-coated on the surface of the sample. Put the coated film into an oven and cure it at 100 degrees Celsius for one hour. Finally, take it out and let it cool down to obtain a 1.5um thick PDMS film. Test the spectrum by infrared and visible spectrometers, and subtract the appropriate size to test the actual cooling effect.

Embodiment 3

[0014] Embodiment 3: The preparation method of organic matter and particulate matter precursor solution is the same as that of Embodiment 1, and the particles used are 100nm TiO 2 . Then start the sample preparation: lay the aluminum foil flat on the surface of the flat plate of the film scraper, spray the prepared particle dispersion on the aluminum foil, and then place it in a fume hood to dry naturally for 20 minutes. Then PDMS was sprayed on the surface of the sample, and the coated film was put into an oven for curing at 100 degrees Celsius for one hour. Finally, take it out and let it cool down to obtain a 1.5um thick PDMS film. Test the spectrum through infrared and visible spectrometers, and cut the appropriate size to test the actual cooling effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com