Preparation method of green regenerated carbon fiber thermoplastic material plate and building template

A technology of thermoplastic materials and building templates, which can be applied to flat products, other household appliances, household appliances, etc., can solve the problems of high price of new carbon fibers, low cost performance of building templates, environmental pollution, etc., and achieve the advantages of recycling, high strength, Easy release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

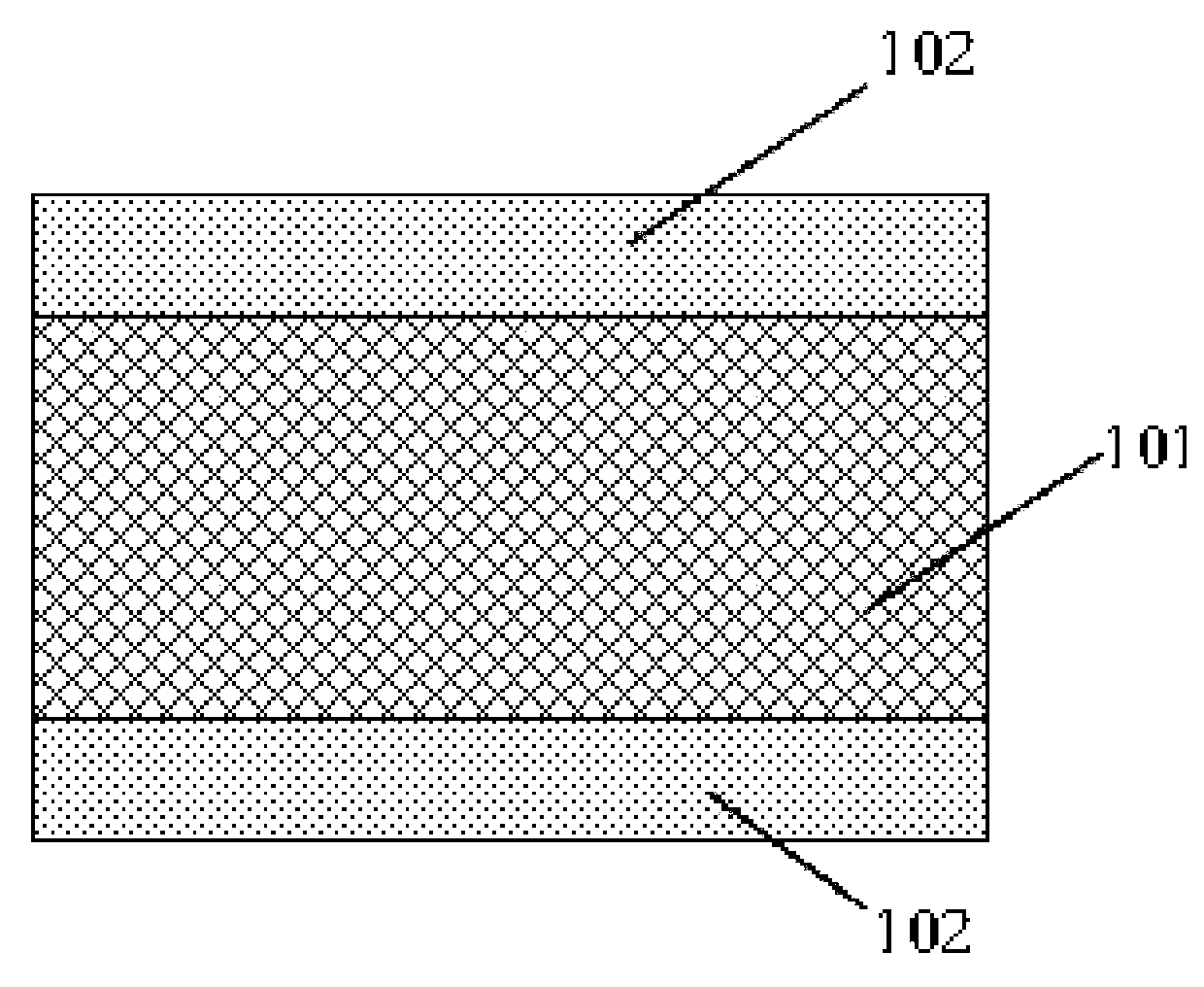

[0041] A method for preparing a green recycled carbon fiber thermoplastic material sheet, the green recycled carbon fiber thermoplastic composite material building template is a recycled carbon fiber thermoplastic material, and the recycled carbon fiber thermoplastic material includes a recycled carbon fiber non-woven felt layer 101 and a thermoplastic resin layer 102; The recycled carbon fiber thermoplastic material includes a recycled carbon fiber thermoplastic material. The carbon fiber nonwoven felt layer 101 and the thermoplastic resin layer 102 are formed by thermocompression.

[0042] In order to further explain this embodiment, it should be noted that the regenerated carbon fibers in the regenerated carbon fiber non-woven mat layer 101 are obtained by recycling carbon fiber composite wastes by pyrolysis; the regenerated carbon fibers in the regenerated carbon fiber non-woven mat layer 101 have a length of 50- 100mm, recycled carbon fiber non-woven felt layer is 50-500g / ...

Embodiment 2

[0045] like figure 2 As shown, a preparation method 1 of a green regenerated carbon fiber thermoplastic material sheet, the specific steps are:

[0046] 1) Preparation of recycled carbon fiber;

[0047] 2) Surface modification treatment of recycled carbon fiber, so that recycled carbon fiber and thermoplastic resin have strong bonding force;

[0048] 3) Preparation of regenerated carbon fiber non-woven felt layer 101: The processed recycled carbon fiber is prepared into a regenerated carbon fiber non-woven felt layer through the non-woven felt production equipment and process;

[0049] 4) Preparation of recycled carbon fiber thermoplastic material sheet: The thermoplastic resin powder and processing aid are spread on the upper and lower surfaces of the recycled carbon fiber non-woven felt layer, and the thermoplastic resin layer 102 on the upper and lower surfaces is formed by hot pressing.

[0050] In order to further explain this embodiment, it should be noted that, a pre...

Embodiment 3

[0052] like figure 1 As shown, a preparation method 2 of a green recycled carbon fiber thermoplastic material sheet, the specific steps are:

[0053] 1) Preparation of recycled carbon fiber;

[0054] 2) Surface modification treatment of recycled carbon fiber, so that recycled carbon fiber and thermoplastic resin have strong bonding force;

[0055] 3) Preparation of regenerated carbon fiber non-woven felt layer 101 and thermoplastic resin layer 102: The processed recycled carbon fiber is prepared into a regenerated carbon fiber non-woven felt layer 101 through the non-woven felt production equipment and process, and the thermoplastic resin fiber is prepared into a thermoplastic resin layer 102;

[0056] 4) The recycled carbon fiber thermoplastic material sheet is prepared by heating, pressurizing and cooling.

[0057] In order to further explain this embodiment, it should be noted that 30-60wt% regenerated carbon fiber fiber and 40-70wt% thermoplastic resin fiber are weighed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap