Invisible orthodontic special three-layer co-pressure composite membrane and preparation method thereof

A composite diaphragm, invisible orthodontic technology, applied in the field of invisible orthodontic treatment materials, can solve the problems of unsatisfactory treatment effect of invisible appliances, low stress relaxation rate, high stress relaxation rate, etc., so as to improve wearing experience and improve strength and impact properties, the effect of low stress relaxation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

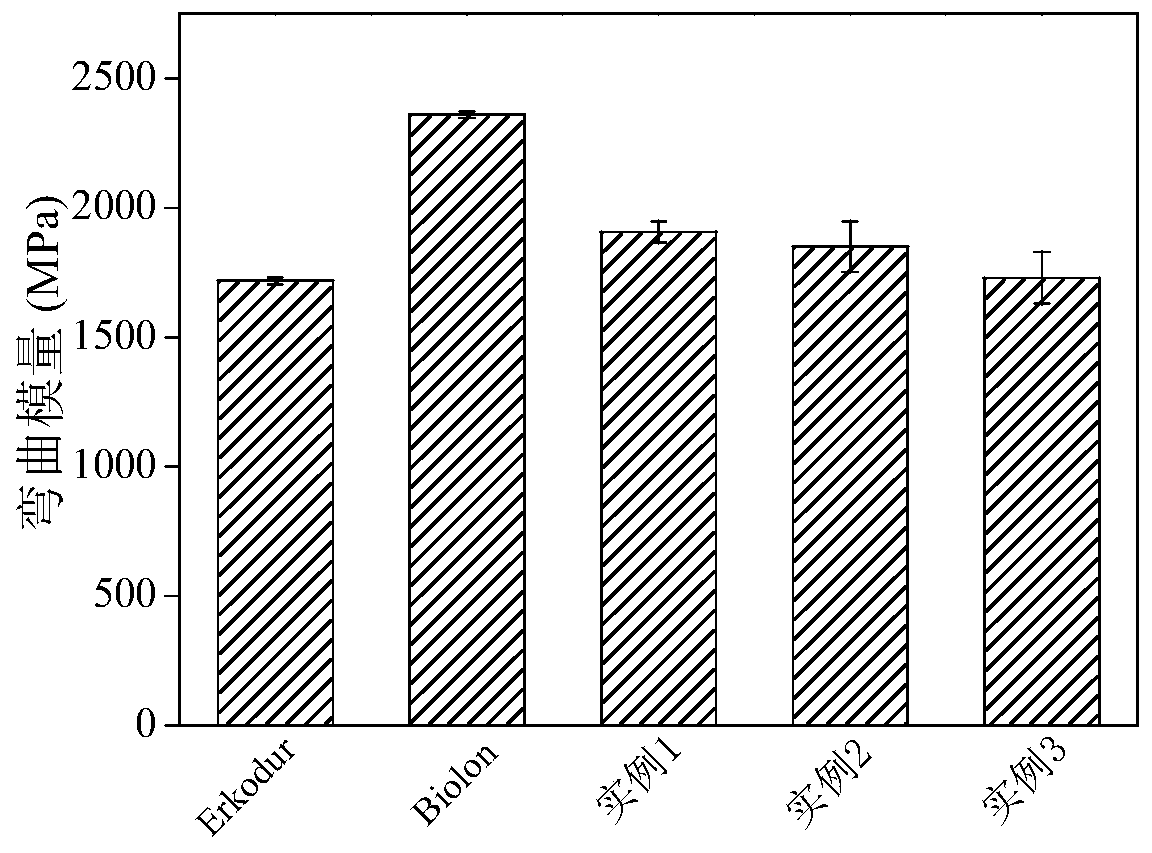

Embodiment 1

[0025] This embodiment provides a special three-layer co-pressed composite diaphragm for invisible correction, which has a three-layer structure. The outer layer A is PETG-BR003 from Eastman Chemical Company of the United States with a thickness of 0.2mm and a hardness of 72D, and the middle layer B is 0.5mm thick. The PVC-S-700 of Qilu Petrochemical Co., Ltd., the outer layer C is PP-180R of Korea SKM Company with a thickness of 0.2mm.

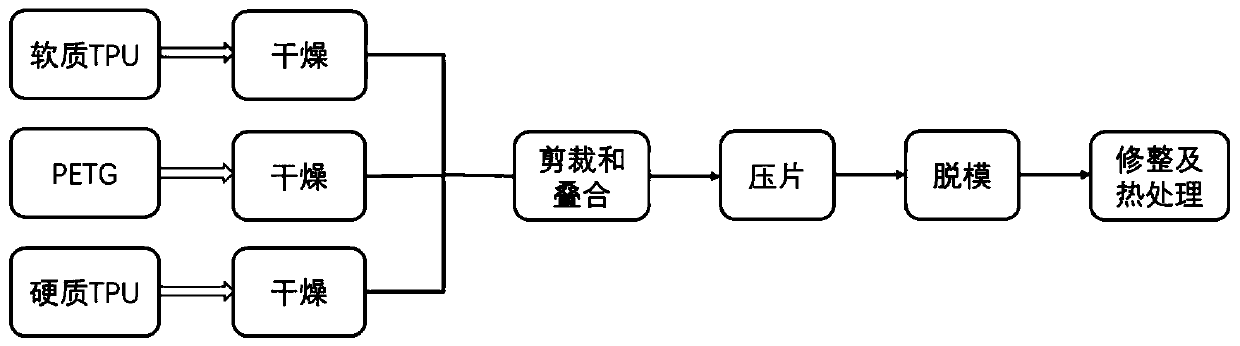

[0026] The preparation process of the three-layer co-pressed composite diaphragm for invisible correction is as follows: figure 2 As shown, the details are as follows: (a) Drying: PETG-BR003 from Eastman Chemical Company of the United States was dried at 70°C for 4 hours for later use, and PVC-S-700 of Qilu Petrochemical was dried at 70°C for 4 hours for later use. PP-180R was dried at 90°C for 4 hours for later use; (b) cutting and lamination: cut the dried PETG, PVC and PP into discs of the same size, then cleaned the surface with ethanol ...

Embodiment 2

[0029] Repeat embodiment 1, difference is: the thickness of top layer PETG-BR003 is controlled at 0.25mm, the thickness of middle layer PVC-S-700 is at 0.6mm, and the thickness of outer layer PP-180R is controlled at 0.15mm. In addition, during the drying process, PETG-BR003 was dried at 85°C for 5 hours, PVC-S-700 was dried at 85°C for 5 hours, and PP-180R was dried at 105°C for 5 hours; during the tableting process, the mold was preheated When the temperature reaches 160°C, put PETG-BR003 between the polyester film layers for preheating, the pressure is 3MPa, and the time is 2min. The outer layer of PP is placed on the two layers of materials for preheating and pressing, the steps are the same as above, and finally hot pressing at a pressure of 8MPa for 3 minutes, and at the same time, the deflation operation is performed every 10s to release the gas between the materials , the final hot pressing time is 6min. Then the laminated material is cold-pressed under a flat vulcani...

Embodiment 3

[0032] Repeat Example 1, the difference is: the thickness of the surface layer PETG-BR003 is controlled at 0.3mm, the thickness of the middle layer PVC-S-700 is controlled at 0.45mm, and the thickness of the outer layer PP-180R is controlled at 0.3mm. In addition, during the drying process, PETG-BR003 was dried at 100°C for 6 hours, PVC-S-700 was dried at 100°C for 6 hours, and PP-180R was dried at 120°C for 6 hours; during the tableting process, the mold was preheated When the temperature reaches 170°C, put PETG-BR003 between the polyester film layers for preheating, the pressure is 4MPa, and the time is 2min. The outer layer of PP is placed on the two layers of materials for preheating and pressing, the steps are the same as above, and finally hot pressing at a pressure of 10MPa for 4 minutes, and at the same time, the deflation operation is performed every 10s to release the gas between the materials , the final hot pressing time is 8min. Then the laminated material is col...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com