Concrete retarder with good uniform mixing plasticity

A concrete and retarder technology, applied in the field of building materials, can solve the problems of unsatisfactory concrete strength and air pollution, and achieve the effects of inhibiting the hydration process of cement, saving labor and prolonging the setting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

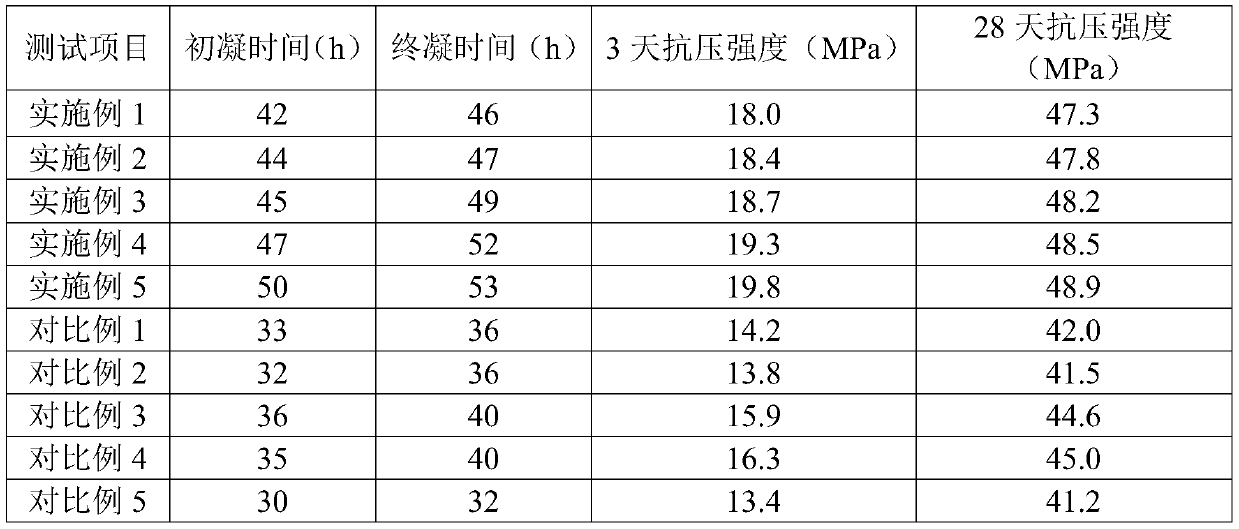

Examples

Embodiment 1

[0028] A well-mixed concrete retarder with good plasticity is characterized in that it is made of the following components by weight: 5 parts of hyperbranched borate ester, 10 parts of porous polysaccharide microspheres, 3 parts of zinc borosilicate, ethylene Potassium trifluoroborate / phosphoenolpyruvate / polyethylene glycol monoallyl ether / 2-acrylamido-2-methylpropanesulfonic acid copolymer 3 parts, attapulgite 10 parts, water 40 parts, alkanes 1 part of phenol polyoxyethylene ether, 3 parts of ethanol, and 3 parts of sulfobutyl-β-cyclodextrin; the particle size of the attapulgite is 50 mesh.

[0029] The preparation method of the ethylene potassium trifluoroborate / phosphoenolpyruvate / polyethylene glycol monoallyl ether / 2-acrylamido-2-methylpropanesulfonic acid copolymer comprises the following steps: Potassium fluoroborate, phosphoenolpyruvate, polyethylene glycol monoallyl ether, 2-acrylamido-2-methylpropanesulfonic acid, and azobisisobutylamidine hydrochloride were added to...

Embodiment 2

[0033] A well-mixed concrete retarder with good plasticity is characterized in that it is made of the following components by weight: 6 parts of hyperbranched borate ester, 12 parts of porous polysaccharide microspheres, 3.5 parts of zinc borosilicate, ethylene Potassium trifluoroborate / phosphoenolpyruvate / polyethylene glycol monoallyl ether / 2-acrylamido-2-methylpropanesulfonic acid copolymer 4 parts, attapulgite 12 parts, water 45 parts, fat 1.5 parts of alcohol polyoxyethylene ether, 3.5 parts of isopropanol, and 3.5 parts of sulfobutyl-β-cyclodextrin; the particle size of the attapulgite is 70 mesh.

[0034] The preparation method of the ethylene potassium trifluoroborate / phosphoenolpyruvate / polyethylene glycol monoallyl ether / 2-acrylamido-2-methylpropanesulfonic acid copolymer comprises the following steps: Potassium fluoroborate, phosphoenolpyruvate, polyethylene glycol monoallyl ether, 2-acrylamido-2-methylpropanesulfonic acid, and azobisisobutylimidazoline hydrochloride...

Embodiment 3

[0038] A well-mixed concrete retarder with good plasticity retention is characterized in that it is made of the following components by weight: 6.5 parts of hyperbranched borate ester, 15 parts of porous polysaccharide microspheres, 4 parts of zinc borosilicate, ethylene Potassium trifluoroborate / phosphoenolpyruvate / polyethylene glycol monoallyl ether / 2-acrylamido-2-methylpropanesulfonic acid copolymer 4.5 parts, attapulgite 13 parts, water 50 parts, alkanes 2 parts of phenol polyoxyethylene ether, 4 parts of glycerin, and 4 parts of sulfobutyl-β-cyclodextrin; the particle size of the attapulgite is 100 mesh.

[0039] The preparation method of the ethylene potassium trifluoroborate / phosphoenolpyruvate / polyethylene glycol monoallyl ether / 2-acrylamido-2-methylpropanesulfonic acid copolymer comprises the following steps: Potassium fluoroborate, phosphoenolpyruvate, polyethylene glycol monoallyl ether, 2-acrylamido-2-methylpropanesulfonic acid, and azobiscyanovaleric acid are adde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com