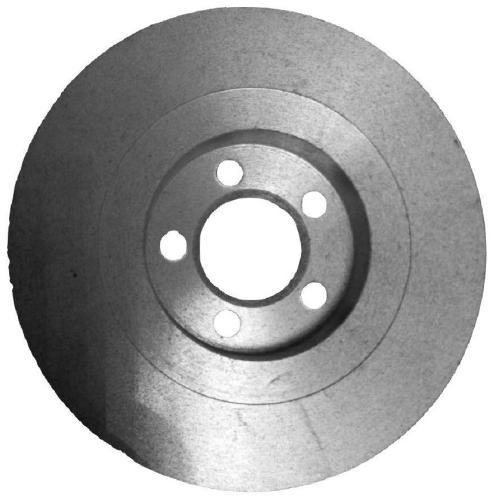

Method for controlling titanium and silicon carbide particles to sufficiently react and brake disc prepared through method

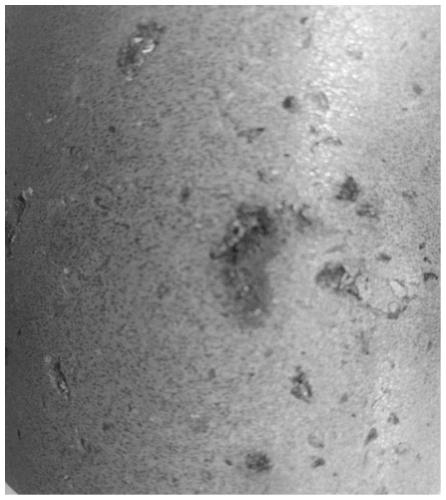

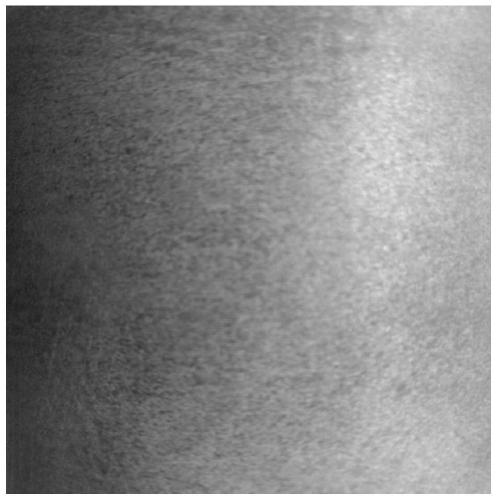

A silicon carbide particle, fully reactive technology, used in brake discs, mechanical equipment, friction linings, etc., can solve the problems of poor fluidity, unstable friction, uneven hard particle silicon carbide, etc., to improve the microhardness and tensile strength, guaranteed cycle life, uniform surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: the method for controlling the full reaction of titanium and silicon carbide particles

[0021] The method for controlling the full reaction of titanium and silicon carbide particles includes the following steps, setting an electromagnetic stirrer in an intermediate frequency stirring electric furnace, recording by mass percentage, preparing 10%-15% of Zn, 6%-15% of Si, and the balance being Al, stir evenly into a mixture in the intermediate frequency stirring electric furnace, after the intermediate frequency stirring electric furnace heats up to 820°C-900°C, mix silicon carbide powder or diamond powder with a mass ratio of 10%-30% of the mixture and 15%-50% of the mass of the mixture The specific potassium fluorotitanate powder is added to the intermediate frequency stirring electric furnace and electromagnetically stirred for 10-60 minutes. After the melt is formed in the intermediate frequency stirring electric furnace, the slag is removed from the melt...

Embodiment 2

[0025] Embodiment 2: the method for controlling the full reaction of titanium and silicon carbide particles

[0026] The method for controlling the full reaction of titanium and silicon carbide particles includes the following steps, setting an electromagnetic stirrer in an intermediate frequency stirring electric furnace, recording by mass percentage, preparing 10%-15% of Zn, 6%-15% of Si, and the balance being Al, stir evenly into a mixture in the intermediate frequency stirring electric furnace, after the intermediate frequency stirring electric furnace heats up to 820°C-900°C, mix silicon carbide powder or diamond powder with a mass ratio of 10%-30% of the mixture and 15%-50% of the mass of the mixture The specific potassium fluorotitanate powder is added to the intermediate frequency stirring electric furnace for electromagnetic stirring for 10-60 minutes. After the mixed melt is formed in the intermediate frequency stirring electric furnace, the mixed melt is added after ...

Embodiment 3

[0027] Embodiment 3: the method for controlling the full reaction of titanium and silicon carbide particles

[0028] The method for controlling the full reaction of titanium and silicon carbide particles includes the following steps: set an electromagnetic stirrer in an intermediate frequency stirring electric furnace, record by mass percentage, prepare 10% Zn, 6% Si, and Al as the balance, and prepare in the intermediate frequency stirring electric furnace Stir evenly in the electric furnace to form a mixture. After the intermediate frequency stirring electric furnace heats up to 820°C, add silicon carbide powder or diamond powder with a mixture mass ratio of 10% and potassium fluorotitanate powder with a mixture mass ratio of 15% into the intermediate frequency stirring electric furnace for electromagnetic stirring After 10 minutes, the melt is formed in the intermediate frequency stirring electric furnace and the slag is removed from the melt. When the temperature is 700°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com