Curable resin composition comprising phthalonitrile oligomers, and prepolymer thereof

A phthalonitrile, curing resin technology, used in applications, inks, household appliances, etc., can solve the problems of low viscosity, mold leakage, etc., and achieve the effect of excellent wettability and excellent processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

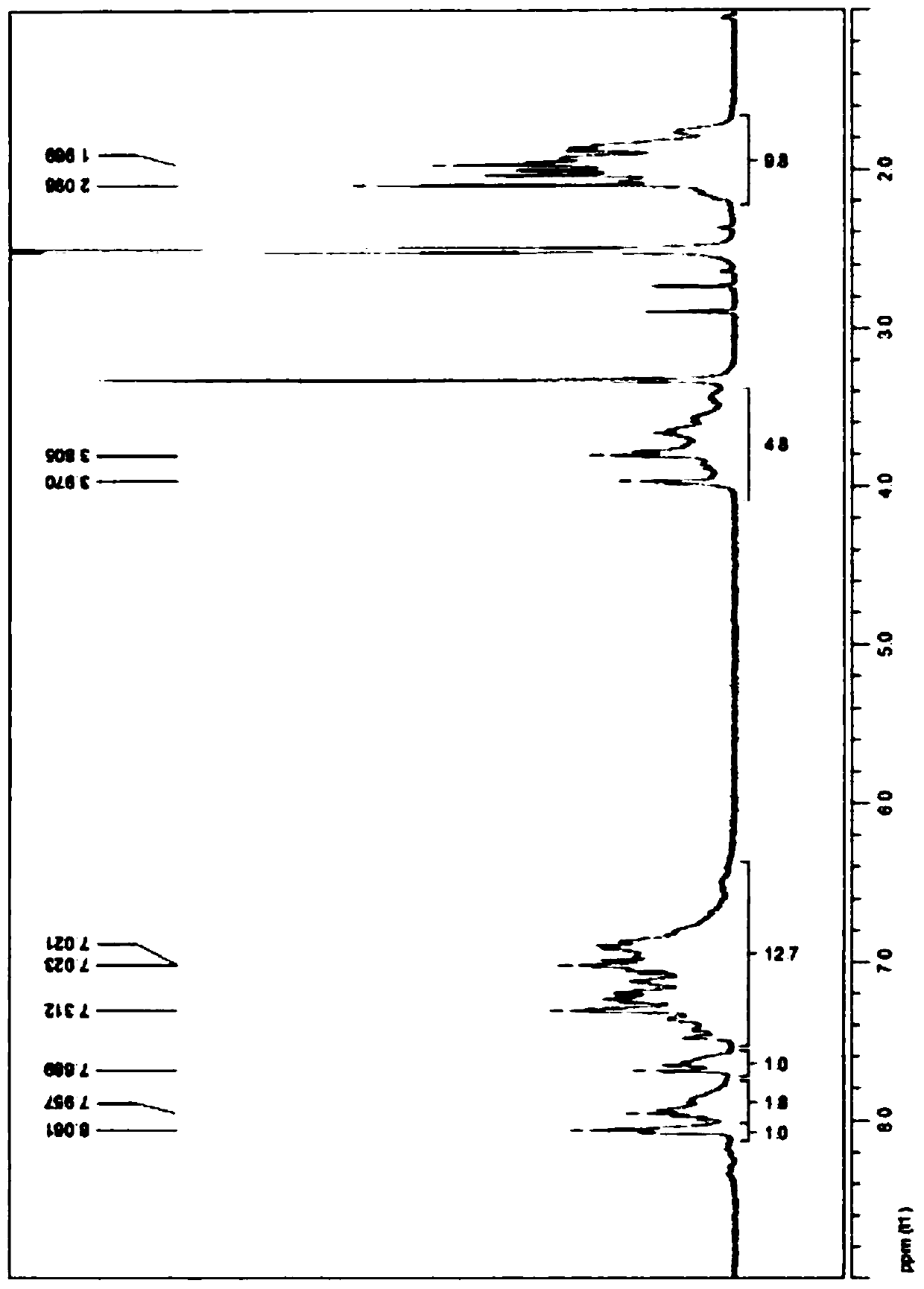

[0237] Preparation example 1. Synthesis of phthalonitrile oligomer (PN-1)

[0238] A phthalonitrile oligomer represented by the following chemical formula PN-1 was synthesized as follows.

[0239]

[0240] 41.1 g of an oligomer represented by chemical formula KA-1 (weight average molecular weight 1,360 g / mol) and 165.0 g of DMF (dimethylformamide) were introduced into a 3-necked round bottom flask, and the mixture was stirred at room temperature to dissolve . 51.9 g of 4-nitrophthalonitrile was added thereto, 70.0 g of DMF was added, and the mixture was stirred to dissolve. Subsequently, 49.8 g of potassium carbonate and 30.0 g of DMF were introduced together, and the temperature was raised to 85° C. while stirring. After allowing the reaction to proceed for about 5 hours, the reaction solution was cooled to room temperature. The cooled reaction solution was poured into 0.2N aqueous hydrochloric acid solution for neutralization and precipitation. After filtering, it w...

preparation example 2

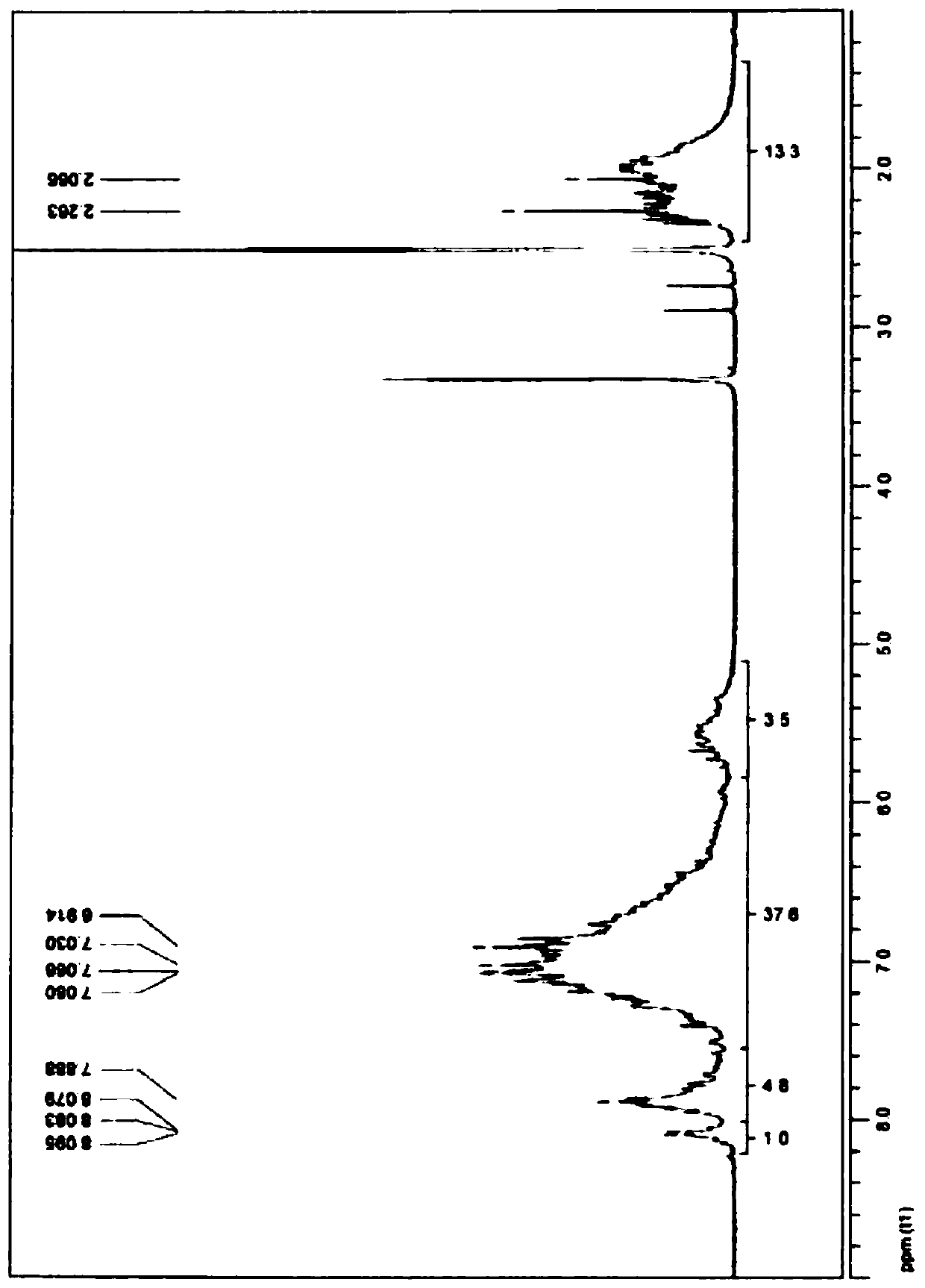

[0242] Preparation example 2. Synthesis of phthalonitrile oligomer (PN-2)

[0243] A phthalonitrile oligomer represented by the following chemical formula PN-2 was synthesized as follows.

[0244]

[0245] 48.0 g of an oligomer represented by chemical formula NE-1 (weight average molecular weight 1,600 g / mol) and 165.0 g of DMF (dimethylformamide) were introduced into a 3-necked round bottom flask, and the mixture was stirred at room temperature to dissolve . 48.5 g of 4-nitrophthalonitrile was added thereto, 70.0 g of DMF was added, and the mixture was stirred to dissolve. Subsequently, 46.4 g of potassium carbonate and 30.0 g of DMF were introduced together, and the temperature was raised to 85° C. while stirring. After allowing the reaction to proceed for about 5 hours, the reaction solution was cooled to room temperature. The cooled reaction solution was poured into 0.2N aqueous hydrochloric acid solution for neutralization and precipitation. After filtering, it w...

preparation example 3

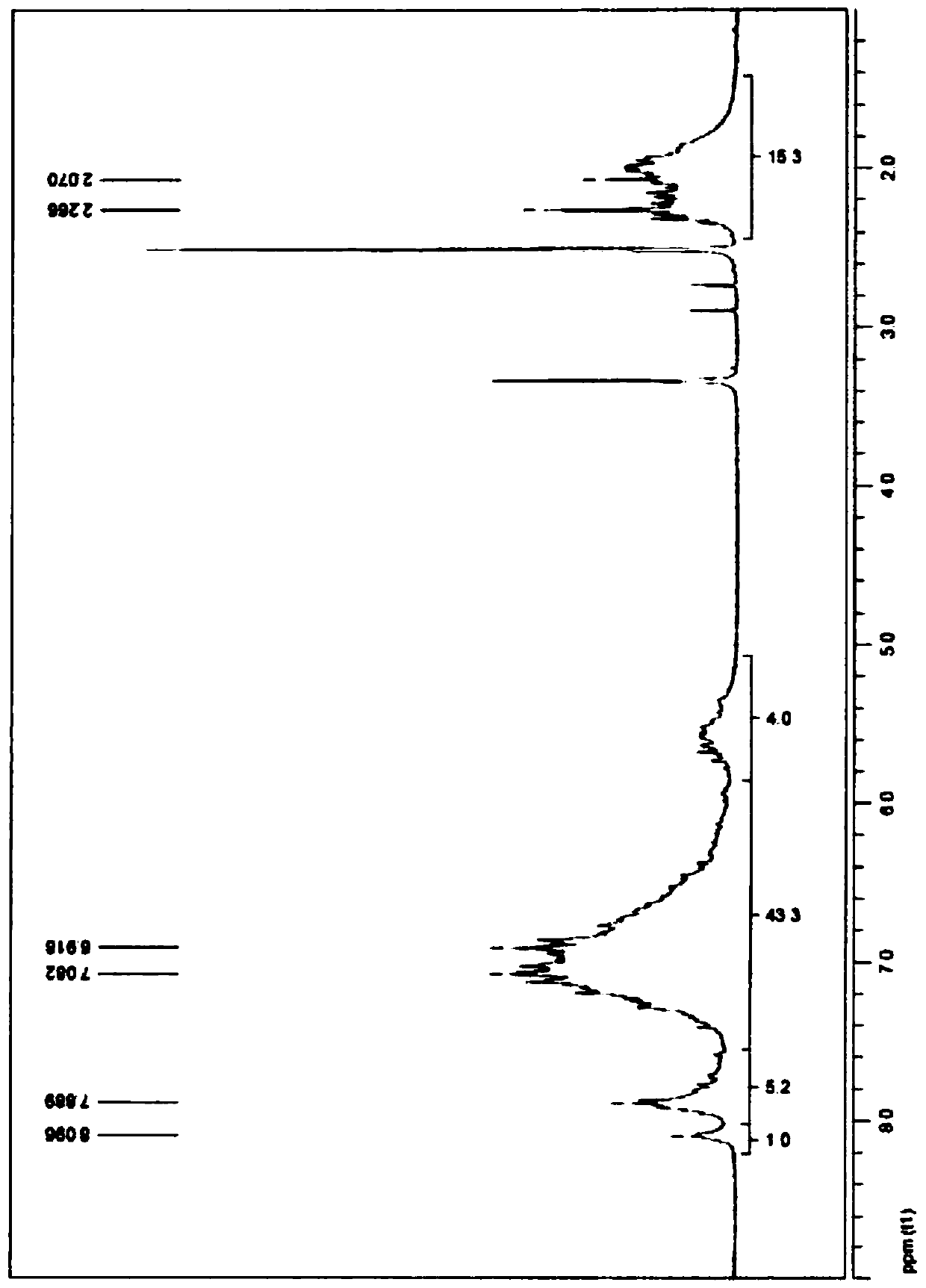

[0247] Preparation Example 3: Synthesis of phthalonitrile oligomer (PN-3)

[0248] The oligomer (PN-3) represented by the chemical formula PN-2 having a weight-average molecular weight of 2,400 g / mol was obtained in a yield of 96% by weight by the same method as Preparation Example 2 except that 1,700 g The oligomer represented by the chemical formula NE-1 of the weight average molecular weight per mol was substituted for the oligomer represented by the chemical formula NE-1 (weight average molecular weight 1,600 g / mol).

[0249]

[0250] image 3 shows the phthalonitrile oligomer PN-3 1 H-NMR analysis results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com